KNIFE MAKING TOOLS: Our belt grinders for knife making are one of the world’s oldest crafts, and while man began by sharpening stones to get the job done, knife making has evolved into an art form of supreme caliber over time.

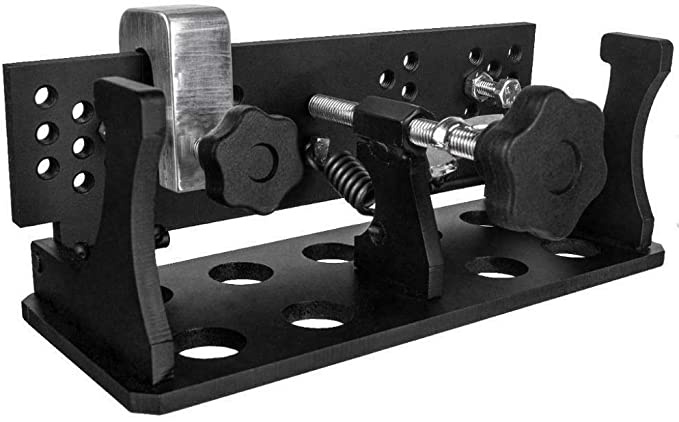

HIGH QUALITY: Our jig grinder angle is specifically designed for knife making and is used for grinding bevel angles on knife blades as well as blank grinding. Using the belt grinder jig relieves strain on the hands and improves the precision with which the belt is ground. The bottom has been polished and slides smoothly across the working table.

The removal of unwanted residue is important because knife making is not an always clean and clear material. Belt knife grinder There is always the possibility of unwanted paint or residue remaining on a surface, and using a belt knife grinder will keep the finish of the surface while removing the residue. Belt knife grinde.

EASY TO USE: Belt grinders are simple to operate and provide your materials with the finishing touch you’ve been looking for in a short amount of time. When used properly, a knife grinder can give you the shape and smooth surface of your knives with the least amount of effort on your part. Avoid tilting the grinder and applying excessive pressure.

FAST ACTION: If you are looking for a belt grinder for knife making, it means that you are looking for something that is more efficient than doing everything by hand. Belt grinders are popular because they allow you to remove material and shape material surfaces in a short amount of time. This is one of the reasons why people choose to use electric knife grinders.

This is the most straightforward and cost-effective jig model available without compromising on quality. The jig is designed for knife making, specifically for grinding bevel angles on a knife blade and blank grinding, as well as for blank grinding. The use of a jig relieves the strain on the hands and improves the precision of the grinding process. All of the parts and contact surfaces have been surface ground and closely fitted in order to achieve the greatest possible perpendicularity, which has an impact on the final shape of the blade. The bottom has been polished and slides smoothly across the working table. Powder coating is used to protect against corrosion. Professional blade smiths have verified the authenticity of this item.

POWERFUL COMPLETE MACHINE.

Knife-making belt grinders are available.

It’s a powerful, versatile machine that can replace a jigsaw, coping saw, or hand file while also removing material and producing a superior finish all at the same time, saving you time and money. This allows you to get into tight spaces while also dealing with irregular shapes.

.

Belt Grinder is a type of grinder that uses a belt to grind materials.

Base with a lot of hef.

Knife Making Belt is a type of belt that is used to make knives.

Knife-Making Instrument.

Jig for Belt Grinder and Knif.

Belt Grinder for Knife-Makin.

Belt Grinders Used in Knife Manufacturin.

Provides additional stability and protectio.

Finished in Powder Coat to Prevent Corrosio.

It is long-lasting and can be used for a long period of time.

.

Manual control is used.

Grinding is the function of this machine.

Electricity is used as a power source.

Model: 8″ Bevel Jig, 200mm in lengt.

Material for the jig is 6 mm AISI 1045 steel.

200 x 80 x 80 mm (8 x 3.2 x 3.2 inch) is the size of the object.

Weight (without the package): 1.5 kg (3.3 pounds).

Clamp made of aluminum alloy 5052 and hardtempere.

Angles are in the range of -15 to 35 degrees. Blades can be angled up to 35 degrees on either side of the blade.

My knife-making experience became more enjoyable.