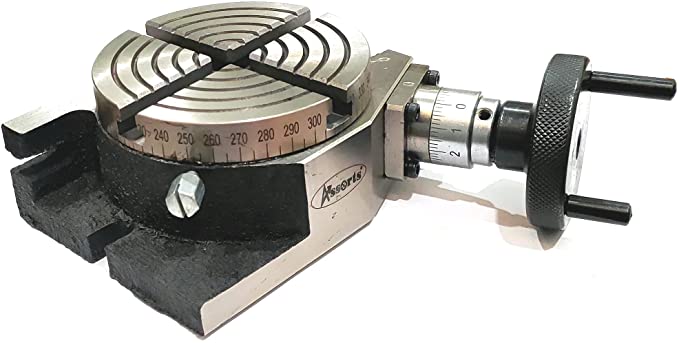

Ne. A lot of very high qualit. The 4″ / 100 mm Regular Rotary Table is made for small milling machines.

There are 360 degrees of rise on the table. Worm Gear Ratio is -1:36, which means that when you turn the handle, the table will move 10 degrees to the left or right.

Cente. The height in a vertical position is 2-1/16″ (50 mm approx. With the hand wheel, you can move it in 10 minute increments. You can also set the hand wheel to zero.

Can be put in both horizontal and vertical positions.

A rotary table that is 4 inches (100 mm) wide is made for small milling machines. It has a 100 mm diameter and is on a tabl. There are 360 degrees of rise on the table. Worm Gear Ratio is -1:36, which means that when you turn the handle, the table will move 10 degrees to the left or right. Cente. The height in a vertical position is 2-1/16″ (50 mm approx. With the hand wheel, you can move it in 10 minute increments. You can also set the hand wheel to zero. Can be put in both horizontal and vertical positions.

As someone else said, I think of these kinds of tools as a set. This one wasn’t any different. Remove the sharp edges with a file first. When that was done, I made a base plate to make sure it would fit on the mini mill. Next, we had to do something about the backlash. In this type of table, there are two types of backlash: one that you can’t fix is the space between the gears and the worm. Other than that, the worm spindle end play is the other thing to watch. To fix it, you just have to take off the handle/knob and the degree ring. Smooth out the ends of the set screws with some emory paper while you have them out. Then, remove the burrs they made on the shaft when they first put it in. The next time you remove the knobs and the indicator ring, you will wish you had done this. Putting them back together, put the degree ring on and then pull the worm shaft like you were trying to get it out. Slide the indicator ring up against the body of the table and tighten the set screw so that it doesn’t move around. This stops the worm shaft from moving at the end. If you do too much, the table will turn very quickly. Then you can turn the knob again. Afterward, the backlash on my was very small. I did this, and the backlash was very small. Make sure that the degree ring is also set up so that it zeroes out when the table is reading 0. To do that, you’ll have to play around a little, but it can be done. Next, we had to put in the lock screw. First, it’s small and made of brass. Over-tighten it, and it will be easy to break off, so do not do that. Drilled out my own 1/4-28 fine thread and tapped it. Then I put a small piece of brass in the hole and screwed in a new 1/4-28 threaded knob. 1/4 – 20 will also work. This means that I can now lock the table without worrying that the small brass screw will break off. I don’t care if the center hole runs straight or not. There is a good chance that it is. If not, I will rebore it and put it back on the machine. You should do these things, because they don’t do them at the factory, which is why it costs less. Even in India, labor is an extra cost. They also don’t work for free.