Ensure straight cuts with these two, simple cutting guides. With these two saw guides, you can use your circular saw to make cuts that rival a table saw’s for speed and accuracy. Like the straightedge guide, the crosscut guide is customized to your saw so you can simply line up the edge of the guide with your cutting mark and clamp it.

I planned to replace it once I settled into my new house, but when the time came to build a room divider/bookshelf unit, I decided to build a couple of my own makeshift circular saw guides instead. The guides are compact and store easily. It’s quick, safe and especially useful when you need to cut a sheet of plywood down to size or to rip a long straight edge on a wide piece of lumber to prepare it for further ripping on a table saw. The only difference is that I put a 1 x 2 stop on the bottom, perpendicular to the 1 x 4 guide, which automatically squares the guide across the piece being cut.

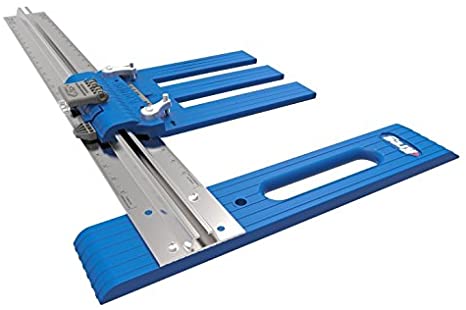

As I looked around for options for breaking down sheet goods in my home workshop, I saw that there are many nice guide systems for circular saws that looked decent. Some guide systems even come with a circular saw, and these look like a great alternative to a panel saw. I wanted something that would deliver a chip-free edge on veneered plywood that would rival what a panel saw or high end guide system could deliver. My solution was a dirt-simple work around; a hardboard circular saw guide that is made custom for my circular saw. With many circular saw guides you have to accommodate the distance from the fence to the blade. If you are tempted to keep the jig lighter by making the fence more narrow, be careful because the width adds rigidity which is critical for an accurate cutting guide, and it also provides more surface for clamping so that the clamp does not interfere with the circular saw operation,. Hold your saw base carefully against the fence as you make this cut, leaving you a base that is perfectly matched to your saw, with a zero clearance edge that will deliver a chip-free cut on veneers.

circular saw guide mdf Related Question:

Can you use a guide rail with a circular saw?

A Guide Rail is designed to be used with a Circular Saw for creating precise and straight cuts every time.

How do you cut MDF straight with a circular saw?

Attach a sturdy blade to a circular saw. To make straight cuts in your MDF, acquire a circular saw that has a cutting speed between 3,000 and 3,350 metres per second (9,800 and 11,000 ft/s). For the best cut possible, install a blade that has at least 60 teeth and a width of about 355 mm (14.0 in).

What can I use as a guide for a circular saw?

Straightedge guide This is the perfect rip cut circular saw guide. To use this circular saw guide rail, line the guide up with your marks, clamp it down, and run your saw along it to make a cabinet-quality cut.

What can I use for a straight edge on a circular saw?

Use a Board as a Straightedge The key is to use a wide board so that you can keep your clamps clear of the motor of the circular saw.

How do you cut MDF cleanly?

To cut MDF without chipping, you need to get sharp carbide tipped blades with a higher number of teeth, clean the table saw and install the blade, adjust it to match the size of the board, start the saw, and push the MDF board along the marked lines until the cut is completed.

What saw blade is best for MDF?

Cutting MDF and man-made materials: Use a 50-tooth to 80-tooth blade. 60-tooth and up blades often make better cuts in dense materials. Plastic laminate: Use an 80-tooth cross-cut blade. You may be able to use a 60-tooth composite blade for thinner materials.

Can I cut MDF with a Stanley knife?

2) You need a utility knife that can be used for cutting atleast 1/2″ MDF. There are many different brands out there, but I personally just use the ones made by Stanley or Olfa.

Which way should the teeth face on a circular saw?

The teeth should be cutting UPWARDS, in a clock-wise direction. You’ll also notice that when your blade is installed correctly, the teeth will be pointing upward. Remember: circular saws (as most saws) cut on the upward stroke.

Are saw guide rails universal?

The YouTool Guide Rail is universally suitable for almost all brands of saw, and is available up to 5 meters long.

Whats the difference between a circular saw and a skill saw?

Circular Saws vs. All skill saws are circular saws. They all have circular blades that spin rapidly to bite through wood. However, not all skill saws are circular saws. Circular saws can be gas-powered, have sidewinder or hypoid designs, or even be fixed to radial arms, which skill saws commonly aren’t.

What is a rip fence for circular saw?

The basic idea of the rip fence is a guide that attaches to the base of your saw and allows you to cut at a fixed distance from the edge of your board.

How do you cut a plywood with a circular saw without splintering?

To do so, place the best side (meaning the side of the door that will be most visible once it’s hung) face down. Then score along the edge of the cut line with a sharp utility knife. Now when you make the cut, the wood fibers will break off cleanly at the scored line, leaving a smooth, splinter-free cut.

How do you use a circular saw without a table?

Fit your circular saw with an edge guide. Set the depth of the blade accurately enough for it to go through the wood and not cut under the surface. Place the guide on base of the circular saw lines and markings you made earlier on the wood. Ensure that the saw is free to move, and the power cord is not entangled.

How do you cut a perfectly straight with a circular saw?

Make the Cut Line your circular saw up with the line you drew. When you turn your circular saw on, make sure that the blade is not touching the board. You don’t want the blade touching anything when you start it. Follow the line with the guide on your circular saw to make your cut.

Why is my circular saw cutting crooked?

What Causes a Circular Saw to Not Cut Straight. A faulty circular saw is likely to have issues such as an unstable blade or a warped blade edge. The problem could also be the way you operate the saw. If you do not operate the circular saw properly, it will not cut straight.