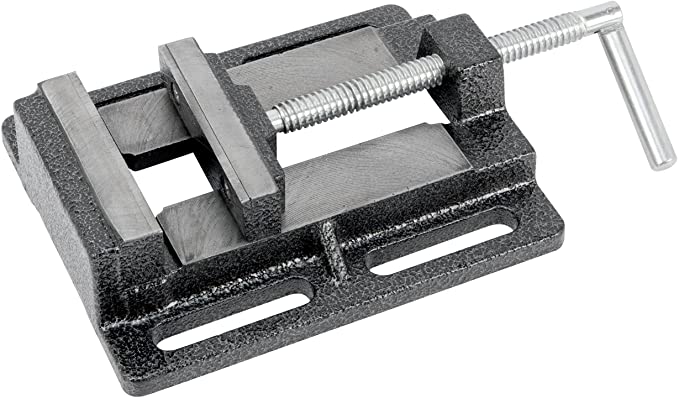

Jaw Opening: 4 inches, Throat Depth: 1-1/6 inche.

Drill press applications such as drilling, tapping, milling, and grinding have been specifically designed for this machine.

The handle is chrome plated and has a durable powder coat finish.

Jaw faces made of hardened steel that can be replace.

The base and slide have been precisely ground.

Drill press applications such as drilling, tapping, milling, and grinding have been specifically designed for this machine. The handle is chrome plated and has a long-lasting powder coat finish. Jaw faces made of hardened steel that can be replaced. The base and slide have been precisely ground. “Jaw Opening Number Four. 1-1/6″ is the depth of the throat.

Okay, when I bought this, I knew I wasn’t getting anything in the line of a machinist tool; after all, I only wanted to use it on my $57.00 Harbor Freight bench top drill press with an 8-inch chuck and chuck chuck. However, this vise did not pass the muster as a $4.00 Dollar Store item, to put it mildly. I’ve already spent more than an hour reworking things on it in order to bring it up to some semblance of a usable standard. The screwed-on jaw faces would not tighten up, despite the fact that the screws were tightened down. It appears that the poorly done job on making the holes in the jaw plates (tampered with) allowed the screw heads to contact the jaw frame before the plates were actually drawn down. I had to cut off the eyelet end of four electronic wire connectors in order to use them as spacers under the screw heads, which left two screws whose heads needed to be filed down in order to be flush with the jaw plates. There is also a piece of metal plate screwed to the bottom of the moving jaw that serves two purposes: first, it holds the jaw into the frame of the vise, and second, it serves as a glide. It looked like it needed to be shimmed, but it didn’t. When the screws were tightened, the plate was only slightly bent. They then backpedalled the screws just a little to allow the jaw to move, leaving the screws loose. In order to fix this, I flattened out the small plate and then found some small washers to use as shims, after which I put blue loc-tite on the screw threads. I turned the metal plate over so that the smooth side would better glide on the vise frame, as the jagged sharp edges had been stamped out with the jagged sharp edges facing upward to dig into the vise frame.

This is the worst purchase I’ve come across in a long time, and I’ve looked around. Now that that has been said, let us look at the bright side: the 2-1/2” vise is the perfect size for the 8-inch bench top drill press. So, because there isn’t anything else I can buy on Amazon to replace it at the moment, I’ll keep it, but I’ll keep looking for something better. I’d recommend looking for a better item for this item, and I’m not being picky about it. AT ANY PRICE, THIS IS NOT A DEAL!