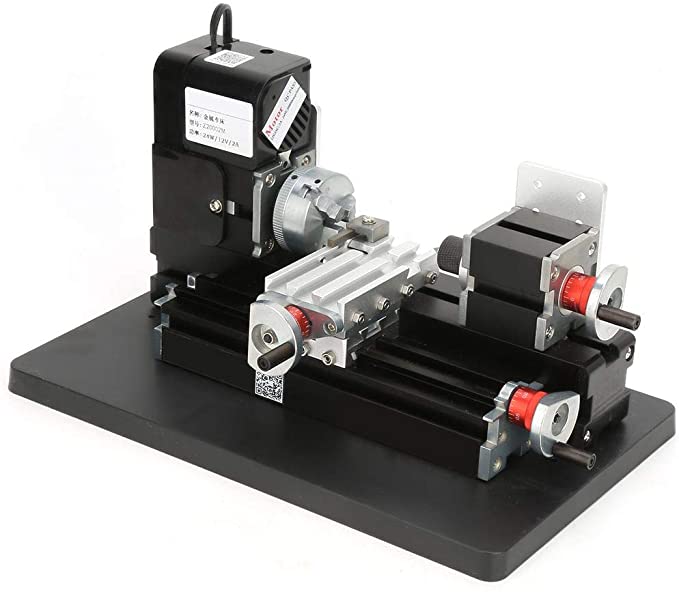

STRONG CONSTRUCTION IS KEY. High-speed steel is used in the construction of the lathe tool. The following are the primary components: headstock, tailstock, long machine bed, big slider, small slider, motor blade, gear, connection block, belt cover, and so on. Except for the belt cover, all of the parts are made of metal. The motor case and the headstock are joined together.

THE PRINCIPLES PARAMETER.

The height of the centers is 25mm, and the distance between them is 135mm. By utilizing a central block, the diameter can be increased to 100mm in diameter. The axis Z slider has a travel of 30mm. The travel of the axis X slider is 160mm. When using the lathe to machine metal, the motor speed is typically reduced to 2000 rpm.

EXTREMELY STRONG MOTO.

You can use it at home because it has a high torque ball bearing motor with a maximum rotating speed of up to 20000RPM and provides extremely strong cutting power while producing low noise.

The hand wheel improves the precision of workpiece processing by increasing the accuracy of scale lines to 0.02mm (0.02mm).

EXTENSIVE APPLICATION.

This mini metal lathe cut off tool, which is powered by a DC motor, can be used in a variety of applications including mini precision parts processing, sample processing, and modeling work. It can process soft metals, nonferrous metals, and precious metals.

A SATISFACTION GUARANTEE is provided.

Warranty for two years, with no restocking fees and no exchange fees.

We guarantee that every customer will be completely satisfied with their purchase; please do not hesitate to contact us if you have any questions about your purchase.

Within 24 hours, you will receive a professional and detailed response from us.

Now is the time to purchase.

Specification.

Motor rotational speed: 20,000 rp.

Voltage, current, and power at the input: 12VDC/2A/24.

Plug voltage ranges from 100 to 240V.

Type of plug: a US plu.

The maximum diameter of the material to be processed is 20mm.

The length of the processed material is 135mm.

Travel of the axis Z slider: 30m.

Travel of the axis X slider: 160m.

Working materials include lignin plastic, soft metal (gold, silver, copper, aluminum, and so on), acrylic, and plastic, amongst other things.

Packagelist.

1 * Mini Lathe (for small jobs.

1 * Power Adapte.

1 x Power Supply Adapte.

a single * Workbench Plat.

1 * Accessory Bag (optional).

1 * Sponge Pad (optional.

Note.

Please make a note if you require a plug adapter or any other special equipment.

When I bought this lathe, I intended to use it to turn spent ammo brass, but I ended up cutting the base and head off with a cut off wheel on my Dremel for jewelry and other projects.

In order to turn the brass cases while cutting them, this lathe has plenty of power.

The large coffee mug in the attached photos required 300 cases cut in three days, which I completed in three days. Since then, I’ve cut an additional 100+ cases for earrings that I’m currently working on. So far, the lathe is in good working order..

The chuck has been the only source of contention for me. It is supplied with two 1/8″ soft metal rods that are approximately 3″ in length and are inserted into holes in the chuck sleeves to complete the assembly. By squeezing the two rods together, you can tighten or loosen the chuck to your preference. I’ve bent both rods to the point of breaking them while attempting to get the chuck tight enough to hold the ammo brass in place. At one point, the chuck was becoming increasingly difficult to open and close without anything stuck in its teeth/jaws, so I disassembled it and coated it with graphite to make it operate more smoothly. While this worked at first, it has since returned to its previous state of being extremely difficult to tighten or loosen. The chuck does not appear to loosen while in use; the jaws simply do not appear to hold tightly to the brass I am turning, no matter how hard I try to tighten it. I have tried everything I can think of.

I currently have enough cut brass to complete my project, but I dread the prospect of having to use it again when I need to cut more. Maybe I’ll see if any other chucks are available for this lathe before making a decision.

Due to the fact that this lathe is not brushless and that the brushes are not replaceable, I also looked into replacement motors for it, just in case. In addition, replacement belts were sought. Unfortunately, I was unable to locate either anywhere. You may be out of luck if you need to replace either of those components depending on how many hours you plan to put in on this lathe in the future.

Given the number of hours I have put into this lathe and the fact that it is still in good working order, I have to say that it is a good little lathe for the money.