Cones are one type of shape.

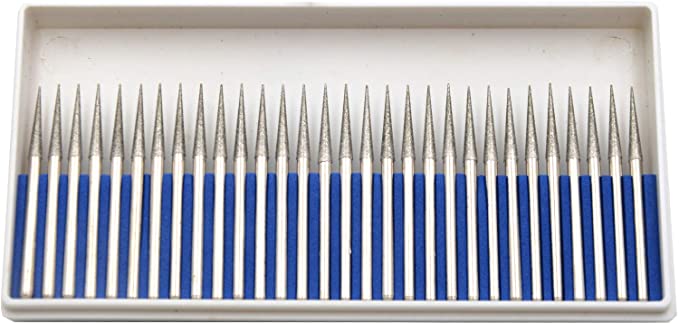

A set of 30 diamond-coated burrs with a 150 grit surface is included.

All burrs have a 3/32″ shank diameter (2.34mm.

Fine detail work, cutting, engraving, carving, touch-ups, and finishing are all possible with this tool.

Recommended for jewelers, lapidary use, craft modeling, home repair, hobbies, crafts, and other purposes, including but not limited t.

T10 3/32 inch shank in T10 siz.

Shape:con.

30 pieces are included in the package.

Shank length is 3/32 inches.

Drilling burr tools are very popular for drilling holes in beach sea glass, stones, and rocks for the purpose of making necklaces, earrings, pendants, and bracelets. This product can be used on a variety of solid surfaces including marble, ceramics, tile, brick, wood, fiberglass, glass, hardened steel, stone, rock carbide, gold, platinum, silver, plastic, and metal.

The following are examples of burr shapes.

bal.

con.

point with a needl.

tapere.

cylinder with a flat to.

ATTENTION: DO NOT USE IN THE DRYER.

Drilling is only permitted in wet conditions. These are delicate diamond drill bits with a very small diameter and a high degree of sensitivity. The diamond coating is only a thin layer of protection. Abuse will not be tolerated. Begin drilling the hole at an angle. Keep the drill in your hand and carefully move the drill around to ream out the sides of the hole while holding the drill in your hand. Allow the tool to do the heavy lifting.

The price is reasonable, and the diamonds are effective in cutting the wood (Butternut). However, the very first bit I used became “locked” in the collet of my electric motor (not a Dremel) handpiece, and attempting to remove it resulted in the destruction of the bur, which was unfortunately one of the most useful shapes offered. The shafts of the burs are plated, and the tolerances are likely to vary from exactly 3/32 inch to a few thousandths of an inch. All of them work fine after I switched to a different, hand tightened collet in a different motor, and I was careful not to over tighten the collet against the bur shafts while doing so.