‘User Guide’ is an abbreviation for “User Manual. Our package contains a CD that contains the installation instructions, a user manual, and the GRBL application software.

Windows XP, Windows 7, Windows 8, and Windows 10 are all supported operating systems. Please let us know if you require any assistance with the machine in question. Also, please let us know if you are unable to install the CH340 driver on Windows 10 using the instructions below.

Wide Range of Applicatio.

The machine is suitable for engraving and cutting soft metals and plastics such as acrylic, pvc, pcb, bamboo, MDF and silimar materials. It is also suitable for carving and engraving copper, aluminum and other soft metals.

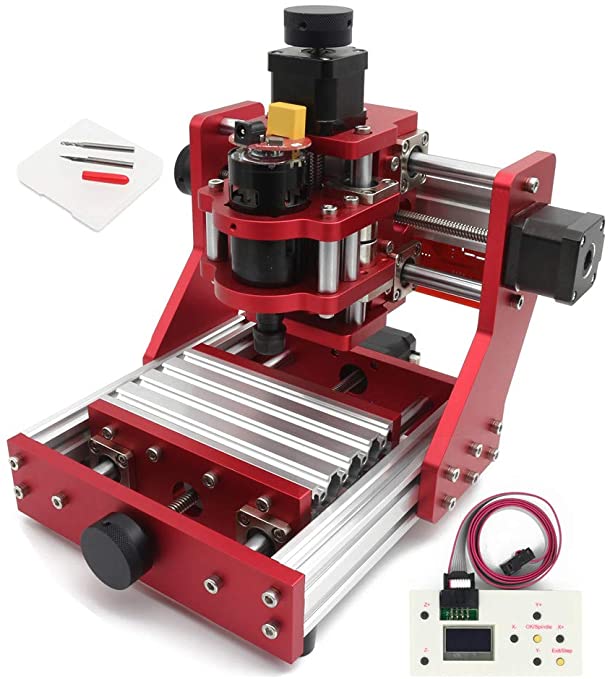

CNC 1310 is an abbreviation for Computer Numerical Control. Grblcontrol, Lite.fire, and Benbox are some of the control software options available. / Working area: 126mm*88mm*38mm/ Machine Dimensions: 281mm*281mm*287.5mm/Control Software: Grblcontrol, Lite.fire, and Benbo. Power is provided by a DC24V adapter (input: 110VAC-240VAC. • Spindle Motor: 775 spindle motor (12-36V), 24V 8000rpm • Spindle Chuck: ER11 • Stepper Motor: 2-phase 4-wire stepper motors • Stepper Chuck: ER11; (1.3A 0.25N.m.

‘Offline Controller’ is a term used to describe a controller that can be used while not connected to the internet.

The following are the primary advantages: 1, it can be used without a computer connected. 2,Supports both SD and TF cards at the same time, with a standard capacity of 1G on each card. can write G-code files or NC files into the root directory of the computer. Suppor. Manually adjust the X, Y, and Z axis locations to determine the engraving starting point, and manually open and close the spindle if necessary.

The first thing you should know about this product is that there are no assembly instructions included with it. Really. Instruction guidelines can be found on YouTube, but some videos may have slightly different instructions than others. With the exception of a few videos, the majority of them will demonstrate how to incorrectly install the slack spring coil. So be on the lookout. When attempting to assemble this machine, be sure to conduct thorough research first. After more than 2 hours of work, I was finally able to put the machine together and get it to work with their control module. This machine, on the other hand, does not come with a driver. A CD is included, which I assume is where the driver can be found, but I’m not sure which computers these days are equipped with a CD player. This is a result of poor planning on the part of the manufacturers. The machine is used by people on YouTube who use open source software to operate it. As a result, you can get around this problem. The working distance required by this machine was the source of my greatest concern. Following the installation of the drill bit, you will only have a 20mm distance between the material you wish to carve and the drill bit. This is a significantly lower price than the one that is advertised. Furthermore, the clamps that are provided are cumbersome and ineffective for small material blocks. When I needed to cut holes and a pattern on a 1.5-inch rod, the clams were on their way and made it impossible to use the tool. In no way, shape, or form will I recommend this machine. The fact that I will not is a shame because I desperately need to CNC some parts.