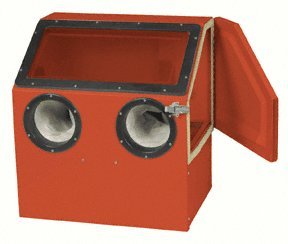

HF sells, only on line, an electric drying unit which works great. I got a good deal on a SnapOn cabinet via Craigslist.

Most abrasive blast cabinet operators choose an air compressor based on the horsepower of the air compressor. If the blast operation requires 80 PSI, then a single stage compressor that operates between 95-125 PSI will work, presuming the air compressor generates enough CFM to operate the blast cabinet. The oil-free rotary screw air compressor utilizes specially designed air ends to compress air without oil in the compression chamber, meaning you get true oil-free compressed air.

Looking for an air compressor for more than just small around the house stuff. I currently own the 3 gallon central pneumatic hotdog. I’m looking for something that has a little more power and capacity to potentially do some sand blasting or maybe hook up some tools to.

01-11-2009, 7:58 AM. I have a full size Harbor Freight blast cabinet I run with a Sears 2hp compressor, 26gal tank. If I remember right, I can blast about 10 minutes full pressure before the compressor kicks on. 01-15-2009, 7:40 AM.An oil/water separator, hose, 30 ounces of compressor oil, media.

best air compressor for harbor freight blast cabinet Related Question:

What size air compressor is needed for a Harbor Freight blast cabinet?

Requires 9.5 CFM at 90 PSI to operate.

What size air compressor do I need for a blast cabinet?

As a general rule when cabinet blasting, use a small nozzle setup (4-8 cfm) for 3-5 HP single-stage compressors and then only plan on blasting on an intermittent basis (to allow proper cooling of the compressor).

What size air compressor do I need to run a sandblaster?

Compressor Size and Efficiency You should use a tank with a minimum of 100 PSI for optimum efficiency with any abrasive sandblasting project. If you work with a lower PSI, you’ll add a significant amount of time to your project.

What PSI should I run my blast cabinet?

The blast pot’s optimum operating pressure is 90 PSI—this ensures the most efficient and effective blasting. Once pressurized, the compressor requires enough air flow to keep the pot at its minimum 50 PSI while still having enough CFMs to allow pressure out at the nozzle.

What is 2 stage air compressor?

In a single stage compressor, the air is compressed once; in a two stage compressor, the air is compressed twice for double the pressure. By increasing the number of cylinder stages and pressure, these machines work more effectively with a faster recovery time, and can handle more tools at once.

What is SCFM vs cfm?

The full form of CFM is Cubic Feet per Minute whereas the full form of SCFM is Standard Cubic Feet per Minute. CFM is always a smaller number than SCFM as it is calculated at higher pressure than the SCFM which makes the air volume smaller.

How much pressure do you need for sandblasting?

What Sandblasting Air Pressure Is Required? The blast pot requires a minimum of 50 PSI. This measure will allow the pop-up valve to seal and the internal pot to pressurize. While operating, the pressure of the pot will typically in the60-80 PSI range to ensure the most efficient amount of blasting.

What size compressor Do I need to spray paint?

While some air spray guns have a rating of lower than 10 CFM, we’d recommend your compressor CFM for spray painting is at least 12 CFM. For professionals, this figure may need to be higher – the important thing is you’ve checked your spray gun’s CFM requirements and chosen a compressor that exceeds that figure.

What kind of air compressor do I need for a paint gun?

For small projects or single panels, your Air Compressor should be rated at 100% of the CFM required by your paint gun. If you’re spraying a whole car, you’ll want 150-200%. For example: A 15-20 CFM air compressor is a good match for a 10 CFM paint gun.

Which compressor is best for sandblasting?

An air compressor which produces between 10CFM – 20 CFM is ideal for smaller sandblasting tasks. While a compressor which produces between 18CFM to 35 CFM is better for larger jobs where a more powerful experience is needed. While an industrial type of sandblasting needs a CFM of 50 – 100.

What kind of sand do you use for sandblasting?

Silica sand for sandblasting. The most commonly used type of sandblasting sand is silica sand. Silica sand is used primarily because it is not only of good quality and durability, but is also usually inexpensive and easily found.

How do you keep a sandblaster from clogging?

At the bottom of the sand blaster tank there should be a valve to regulate the rate of sand flow that enters the hose. Try closing this valve while opening the blasting nozzle then slowly open the sand flow valve. I have found that too much sand entering the hose causes it to the nozzle to clog or the hose to clog.

Do Soda Blasters work?

Soda blasting is particularly effective at removing light rust, mill scale, spray-paint graffiti, and fire damage soot without damaging the base material underneath.

Is higher CFM better air compressor?

A compressor with a higher CFM rating can deliver more air and is better suited for heavier applications, such as operating air wrenches and framing nail guns.

Which is better a single stage or two stage air compressor?

In general, two-stage air compressors are more efficient, run cooler and deliver more CFM than their single-stage counterparts. While that may seem like a convincing argument against single-stage models, it’s important to realize that they have advantages as well.