Install the blade and apply just enough tension to keep the blade securely on the wheels. Instead, tension the blade until your finger is only able to deflect the blade by about 1/4″. This test should be done at the back of the saw where nothing can get in the way of the blade. Adjust the thrust bearings carefully so that they do NOT rotate while the blade moves, but they DO begin to rotate as soon as light pressure is applied to the blade.

Even a low-end bandsaw blade tension meter can cost $300. If you use your bandsaw a lot or are doing delicate work, having the proper tension on the blade can be critical and the only way to accomplish this is with a bandsaw blade tension meter. With the bandsaw blade properly installed, and tensioned, and the blade guides properly set, the next issue is to make sure that the bandsaw table is square and level. We suggest that you go through the setup steps in this how to set up a bandsaw properly: the ultimate g guide before starting a new project and each time you change your bandsaw blade.

The first thing you need to do is install the blade. Remember, do not push too hard but rather adjust the amount of pressure and monitor the blade tracking. A known fact is if the blade slides in the cut slot easily, the table is 90 degrees to the blade.

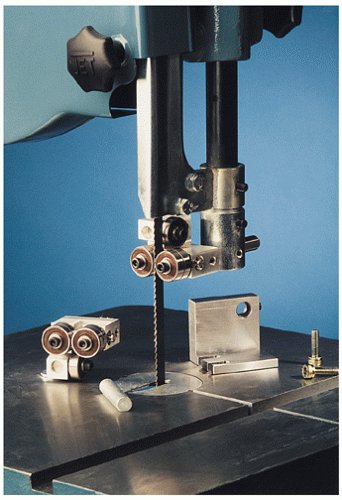

A bandsaw will only cut accurately if the blade guides are set correctly, so these are important. Some people have the bearings touching, others don’t, we tend to side with the latter and like them to be set around 0.5mm either side of the blade. Simply place the Buddy up against the blade, using the recess to counter the tooth set.

Whether you’re a beginner or could just use a refresher, we’re going to walk you through the process for a perfect bandsaw blade adjustment setup every time, no matter what blade you install. Lower the upper blade guide, open the wheel housing(s) and blade guard and carefully remove the blade. So it should be no real shocker that you’ll encounter conflicting schools of thought regarding blade placement on the wheels and how it affects blade “Drift”.

The band saw set up is to carefully install and align the blade. So being aware of how to set up the blade tension should be your priority step in bandsaw set up process. If the side guides come to contact with the blade or set at the parallel position to the blade teeth then the blade can be broken when it moves.

how to set up bandsaw Related Question:

How close do you set the side guides on the band saw?

The front of the side guides should be located about 1/16″ back from the deepest part of the blade gullets. You don’t want the side guides to contact the cutting teeth of the blade since the teeth flare out at a slight angle. This adjustment is made to both the top and bottom guides.

How far should the safety guard be above the stock?

Use a guard that is high enough to cover the part of the blade rising above the stock and wide enough to cover the blade when it is tilted. The blade height should be set so it does not extend more than about 3 mm (1/8 in) above the height of the piece being cut.

What must the operator do before operating the bandsaw?

Before the start of any sawing operation, the bandsaw machine operator needs to check the electrical connections — saw to power source. Look for cable splits or crimps and assure that a fork lift or other shop equipment are not inadvertently left near or plugged into a needed outlet.

How much tension should a bandsaw blade be?

For carbon steel toothed blades (cutting blades) this is typically 15,000 to 25,000 PSI. Slitting type blades typically are tensioned in the range of 12,000 to 20,000 PSI. In general bandsaw blades are never tensioned past 35,000 psi.

Why does my bandsaw blade keeps coming off?

Blade Tension Is Too Loose The most common reason why the blade is slipping off is that there isn’t enough tension to keep it on. Blades can slowly become loose after years of wear and tear, and eventually, you’ll need to tighten or replace them.

Where should you never place your hands while cutting on the bandsaw?

Always keep your hands on the sides of the blade while operating. never in front of blade!

What should be used to remove scrap stock from the bandsaw table?

Always use scrap wood to push or move scrap wood away from the blade. 13. Never leave the machine until it has come to a complete stop, then clean the table off by using a table broom, never your hands.

What should you not do with a bandsaw?

Never push on back of piece with fingers or thumb. Don’t reach across the blade. Make all cuts under power, not while blade is coasting. Never remove guard unless authorized by Technician or WRL Manager.

Can you rip wood on a bandsaw?

A band saw can shape curves, saw rough lumber safely, cut joinery, and even rip boards to width.

What is the number 1 safety rule of the band saw?

Band Saw Safety Rules from Mark Adams: 1. Follow the 3” rule from the blade; always keep fingers 3” from the blade. 2. Check the blade tension and tracking before starting.

Should you wear gloves when using a bandsaw?

Do not wear gloves while using a bandsaw (or any powered saw, drill press, or planer for that matter). The gloves will give you a false sense of security and do very little to protect your hands. In fact, they may end up getting your fingers pulled into the blade if the material catches.

What is the closest you should put your fingers to the blade while it is running?

Do not put your fingers closer than two inches from the blade. 3. Do not place your hands directly in line with the blade while cutting stock. 4.

What are the two safety checks you need to perform before turning on a bandsaw?

PRE-OPERATIONAL SAFETY CHECKS Ensure all guards are fitted, secure and functional. Do not operate if guards are missing or faulty. Check workspaces and walkways to ensure no slip/trip hazards are present. Ensure push stick is available.

What causes bandsaw blade drift?

Drift is cause because the blade buckles under the load. You can see that by stretching a ribbon between 2 points and applying a pressure to one of the edges, it will turn sideway easily. A sharp blade and high blade speed will help a lot with that.