Learning how to build a bandsaw mill can be quite the undertaking. Read on for some free bandsaw mill plans you can do yourself! As you can probably tell, learning how to build a bandsaw mill won’t be right for everyone.

Irish,find a local mill have a good look at it and take pictures and measurements. My opinion on the subject- I had a mill built from the Rake plans, and while it was workable, it left a lot to be desired. I am also about to mount a band mill sawhead on my Swingblade mill, for a dual action mill.

To build a sawmill on your own, with or without a guide, takes proper planning calculations, and most importantly depends on the materials and tools used. The good thing about this guide is that you can also make it a mobile portable sawmill because it’s metal and there is a spot in the build that can accommodate two wheels. This is the last DIY on a sawmill and it’s a cheap DIY project.

Ly/2BMQUjS. Before jumping in to the build let me first explain what a bandsaw mill is and the prep work that went into the few weeks leading up to the guys arriving. Matt is actually a fine woodworker but he learned how to weld and build a mill so he could slab his own material. In the next video, we will continue the build with building out the carriage.

best bandsaw mill plans Related Question:

How much does it cost to build a saw mill?

The cost of a portable mill is about $1,500 for the base mill, plus an optional $500+ for a mechanical jack-hoist to get the logs up on the bed. A stationary mill, with all components but the engine bought new, would cost $5,000 or $6,000, and about half that used — and you still have to install it.

Can you make money with a bandsaw mill?

A portable sawmill can be worth the investment. It can provide a source of wood for your own projects and give you a side business. For a source of lumber, as well as a profitable business, a portable sawmill can be a key piece of equipment on your farm.

How much does a bandsaw mill cost?

New portable sawmills range in price from less than $4,000.00 to over $80,000.00 depending on the amount of production you need.

How much is a bandsaw mill?

Prices and Resale Value The small manual mills start at around $3,000 and go up to around $10,000 depending on the size of the mill. Mid-size sawmills range in price from $6,000 all the way to $20,000.

Who is Matthew Cremona?

Matt Cremona is a full time woodworker who produces videos about woodworking and milling lumber. His furniture projects span the full woodworking process from tree to finish.

Is running a sawmill profitable?

It’s true that owning a sawmill can be a very lucrative business venture, and in the right circumstances it is not only possible but very likely to earn you a significant profit on a regular basis. However, it’s worth keeping in mind that building a business with only profit in mind is not sustainable in the long term.

How long should pine dry before milling?

Depending on the thickness of the lumber and where you live, weather and time of the year, it will take anywhere from 6 weeks to 4 months. Most lumber is in the 1” to 2” thickness and the time above applies to thicknesses. Drying cants, timbers, posts will take considerably longer.

Can you make money selling rough cut lumber?

When you first get a sawmill, the primary ways to make money are selling lumber or cutting for people. However, cutting for people is kind of tricky, because you’ll want to have some experience before you start doing that. If you’re cutting by the board foot and you take your time it doesn’t really matter too much.

How long do portable sawmill blades last?

Some can last under six months, and some can last years! Some of the most important variables to consider are what you are cutting, the condition of the machine and blade, how long you are using the blade, and even how you are feeding the wood through your saw as well.

Where are Wood Mizer sawmills made?

Wood-Mizer is a sawmill manufacturer that also produces sawmill blades. Modern manufacturing facilities in Indianapolis and Batesville, Indiana USA and Kolo, Poland guarantee maximum quality at an affordable price anywhere in the world.

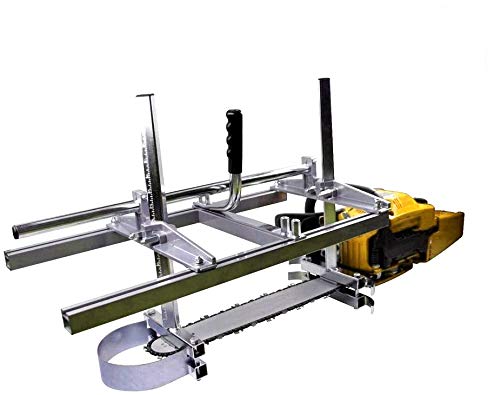

Are chainsaw mills worth it?

A chainsaw mill is one of the most efficient and effective tools when it comes to converting wood into lumber. Lumber is a very effective raw material that can be used for a variety of purposes. Be it for firewood or be it for construction purposes, you can certainly utilize lumber for whatever you need.

What size chainsaw do I need for an Alaskan mill?

Most Alaskan mills require at least 3 inches extra at the end of the bar for attachment. I also recommend going with a saw with an engine size of at least 60cc for smaller logs and softer woods. A minimum of 90cc would be best though.