“To find the correct tension, you can start with the tension scale on your saw, but you will probably need to fine tune the adjustment. With the saw unplugged, increase the tension on the blade until pushing on the side of the blade with your finger using a moderate amount of force deflects the blade about a 1/4” from its normal position. When too much tension is put on the blade, premature blade breakage and poor tracking can occur, but most important, you can damage your machine by trying to make it reach a blade tension greater than the machine was designed to operate at. The answer is yes, so be careful not to over tension your bandsaw blade.

On a machine with screw over spring tensioning, the most common on smaller machines, only really dependable way to set the blade tension is with a blade tension gauge. The machine manufacturer will provide a chart showing how much blade force is generated by any air pressure, and the blade tension in typical blade sizes. Over tightening the blade will shorten the life of the blade wheel rubber, bearings, and blade.

Running your bandsaw blade tension too loose can cause your blade to come off track another dangerous situation. Then you adjust the bandsaw blade tension to reflect what the manufacturer recommends the blade tension should be. The bandsaw blade flutter test, my opinion probably one of the best ways to properly set up blade tension.

We’ve seen various methods for setting bandsaw blade tension, from fancy gauges to plucking the blade like a guitar string. Turn the tensioning handwheel until the tension gauge is at or a little above the recommended tension for your blade width. With the saw running, slowly release the tension-about 1⁄2 turn of the tensioning wheel at a time-until the blade starts to flutter, as shown at right.

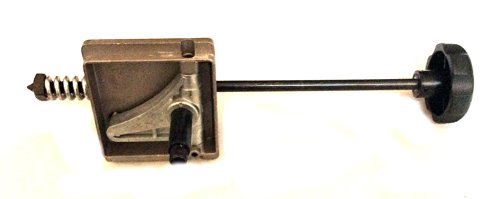

Bandsaw tensioning After I built my home made bandsaw, I wanted to get a better idea of how much tension I was putting on the blade. “Bandsaw blades can take 15,000 PSI of tension. A greater limit is how much force your bandsaw can take. From my measurements, given the limitations of a typical bandsaw, it’s just about impossible to over-tension any but the narrowest of bandsaw blades. 70 pounds is more than my 14” bandsaw is capable of. Home made tension gauge Because clamping a caliper to a bandsaw blade is awkward and can damage the blade, I built myself a simple bandsaw tension gauge using some birch plywood and a dial indicator.

how to build a bandsaw table Related Question:

How high should a band saw table be?

For the small shop furniture maker, go with 14″ as the minimum for a bandsaw, though 16″ is better. Those doing larger work might even want 18″ or 20″ machines. Just make sure you have a minimum resaw height of 12″ for versatility.