I’ve freehanded pieces through the bandsaw, but the cuts aren’t straight, and working unstable round shapes on a bandsaw scares me. Bandsaw blades can drift to the side when using a fence that is parallel to the blade or when using the miter slot as a guide, so I minimized that three ways: I centered the blade on the crown of the bandsaw wheels, used extra blade tension, used a sharp blade, and went with a slow feed rate to minimize deflection caused by pressure and heat. Having made two cuts with the sled I can continue working using the usual fences on the bandsaw or tablesaw.

1) Every log sled relied on the miter slot to make straight cuts. This puts the weight of the log out near the end of the table on an already top heavy band saw. When using my log stabilizer / log sled / log jig, I make my first cut, then flip the log, so the flat side rests on the table.

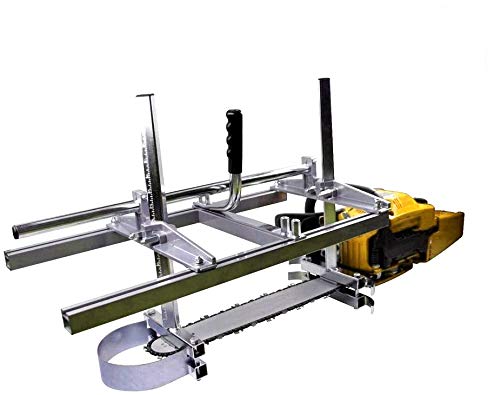

Bandsaw sled for milling small logs At a wood show, I saw somebody selling a neat metal jig for cutting lumber off small logs on the bandsaw. The picture at left shows the sled having just been used to cut the side off a piece of crabapple lumber that I cut off one of the trees in my yard when I pruned it. So after cutting one side off, rotate the log 90 degrees, make another cut, and then make the rest of the cuts with a regular fence.

The first time you run the sled through, it will trim the sled to the perfect width. The wood of the sled and the pipeclamp makes the sled fairly heavy. To make the sled more functional I used a combination square and a pencil to run pencil lines down the entire lenght of the sled.

I’ve wanted to try milling small logs on the bandsaw for a while now, so after our neighbors had a couple of poplar trees taken down it was finally time! To keep the logs from sliding around, I cut a piece of drawer liner and used a little spray adhesive to keep it in place on the MDF. For the first cut on each log, I also used wooden shims where they were needed to prevent the log from rocking. “For these cuts, I used a 3/4” 2-3 TPI Timberwolf blade on the bandsaw which did a good job.

Loading the log onto the sled can be facilitated with a cable winch and a ramp to avoid exertion and injury while handling larger logs;. The Sled serves three purposes: Supporting the log and make contact with the Rollers, Securing the log so it does not shift as it is being fed into the bandsaw blade, and travel through a perfect line. The Log Mill Disassembled The Bandsaw Log Mill in Action Possible Improvements to the Design: Install cross-braces on the legs to make the Table Support stiffer.

bandsaw log milling sled Related Question:

How do you cross cut a log?

The basic technique is to start with a meeting cut through one third of the log from the side that is exposed to compressive stress – that is the side where you expect the guide bar to pinch. Then continue to cut a meeting cut on the opposite side until the log is cut through.

How do you cut thin wood slices?

To cut your wood slices, we strongly recommend you have either a miter saw or band saw. These are the best saw options to use when cutting log slices, as they can make more precise cuts with the uneven nature of a log. They can also cut thicker pieces of wood than other types of saws.

How thick of wood can a band saw cut?

Band saws are the undisputed champ when it comes to cutting curves and slicing through thick material. Many small band saws can slice though lumber a full four inches thick, and bigger saws handle six-inch cuts.

How do you smooth rough cut wood?

The proper way to sand wood is to start sanding with a sanding grit coarse enough to remove the debris and expose the wood grain. Then, sand with a slightly higher grit to remove the scratches caused by the coarse grit. Repeat this process until you reach 220 grit.

What are the disadvantages of quarter sawn lumber?

Quarter-Sawn Lumber produces much less usable lumber than Plain-Sawn lumber, making it more expensive. It is often still sought after becuase it is more stable. It is less likely to cup or twist and there are fewer surface checks and splits. It also wears more evenley.

How much more is quarter sawn oak?

For low/medium fleck quarter sawn you can expect to pay between $4.08 to $24.20 per board foot based on 8” to 16” widths. For higher fleck quarter sawn it is approximately $4.58 to $27.20 based on the same widths. Use your square footage measurements to calculate how much the planks will cost you in total.

What is the smallest diameter log worth milling?

I always tell my customers that anything smaller than 8″ on the small end is usually not worth the trouble. Some customers take it to heart and some will throw in everything down to 4″. I will saw a 6″ log if it’s straight but the 4 and 5 inch stuff usually gets put aside.

How long does it take to mill a log?

The time/cost to saw the logs depends mostly on the log’s size and species. As a very rough estimate, a 12″ diameter 8 foot long log will take around 25 minutes; an 18″ diameter 8′ long log will take around 40 minutes to saw; 24″ diameter will be at least 1 hour.