Learning how to build a bandsaw mill can be quite the undertaking. Read on for some free bandsaw mill plans you can do yourself! As you can probably tell, learning how to build a bandsaw mill won’t be right for everyone.

If you don’t do much welding or fabrication, I wouldn’t recommend building a mill. From contributor R: I was thinking at one time of building my own mill until I came across a Turner mill. I would urge anyone thinking of building a mill to remember Murphy’s law and build to make a mill as safe as possible.

To build a sawmill on your own, with or without a guide, takes proper planning calculations, and most importantly depends on the materials and tools used. The good thing about this guide is that you can also make it a mobile portable sawmill because it’s metal and there is a spot in the build that can accommodate two wheels. This is the last DIY on a sawmill and it’s a cheap DIY project.

A homemade sawmill will provide you with the ability to cut logs into lumber cheaply and efficiently. Take a sawmill along with you so the cut logs can be milled on-site to reduce the number of times the logs have to be moved. The sawmill is not too big, yet it is powerful enough to cut hardwood logs into lumber.

how to build a bandsaw mill Related Question:

How much does it cost to build your own sawmill?

The cost of a portable mill is about $1,500 for the base mill, plus an optional $500+ for a mechanical jack-hoist to get the logs up on the bed. A stationary mill, with all components but the engine bought new, would cost $5,000 or $6,000, and about half that used — and you still have to install it.

How much does a mill cost?

Generally, the less expensive the mill, the lower the production. New portable sawmills range in price from less than $4,000.00 to over $80,000.00 depending on the amount of production you need.

How long should pine dry before milling?

Depending on the thickness of the lumber and where you live, weather and time of the year, it will take anywhere from 6 weeks to 4 months. Most lumber is in the 1” to 2” thickness and the time above applies to thicknesses. Drying cants, timbers, posts will take considerably longer.

Can you make money with a bandsaw mill?

A portable sawmill can be worth the investment. It can provide a source of wood for your own projects and give you a side business. For a source of lumber, as well as a profitable business, a portable sawmill can be a key piece of equipment on your farm.

How much does a bandsaw mill cost?

Prices for a swing-blade sawmill can range from $6,000 to $40,000, with $20,000 about average.

What is a bandsaw mill?

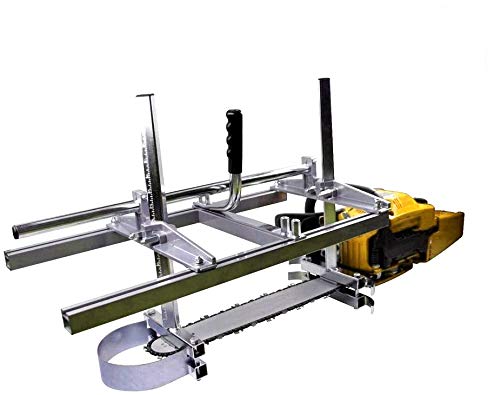

A band sawmill is made up of a saw head with 2 band wheels. They have a flexible steel band blade that tracks around the band wheels. It has a frame with a track that guides the saw head through the log. The operator or sawyer pushes the saw head into the log to cut.

Is it worth it to mill your own lumber?

Milling your own lumber can produce quality material for a fraction of the price of a lumber dealer. In fact, if you purchase your own mill, like I have, you can actually make a profit off of it by selling lumber to other woodworkers and by offering to mill other people’s logs.

Can you build with fresh cut lumber?

Building with green lumber for timber frame construction can save time, money and energy. With green timber, you can begin building right away without having to wait for the wood to dry, or having the added cost for kiln drying, which uses environmentally damaging fossil fuels during the drying process.

How thick of wood can a band saw cut?

Band saws are the undisputed champ when it comes to cutting curves and slicing through thick material. Many small band saws can slice though lumber a full four inches thick, and bigger saws handle six-inch cuts.

Is it better to mill logs green or dry?

Cutting the logs green allows you to control splitting. If the logs are drying, they have either begun to split or are building stresses that will lead to splitting. So saw your logs as close to green as possible. It just happens that wood is easier to cut when green.

Should you let logs dry before milling?

Summary: Logs should be milled for drying as soon as possible, and the ends should be sealed as soon as they are felled. A bandsaw mill will create less waste than a chainsaw mill.

How long should wood rest after milling?

When I bring wood into the shop for a project I usually let it adjust for about two weeks before doing anything to it.