With the Tormek sharpening system, you can use your bench grinder to shape.

Tormek jigs can be used with your bench grinder.

With or without a Tormek machine, you can still use the precise Tormek jig system on your bench grinder to get the shape and angle you want. You can do this quickly and easily.

It comes with a height-adjustable block and all the tools you need to attach it to your work bench.

The method for setting the shape and edge angle is the same no matter which machine you use.

Amazon.co.

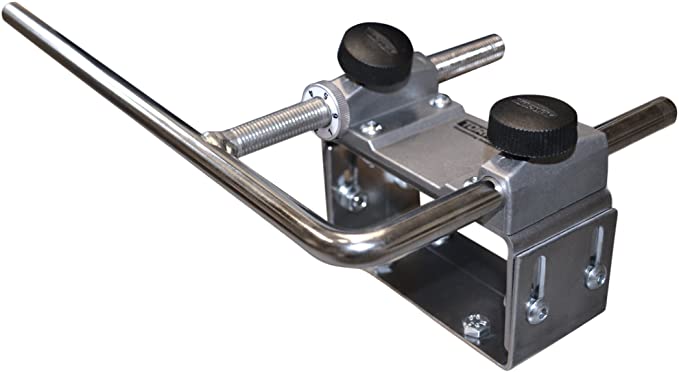

With the help of the BGM-100 bench grinder mounting set from Tormek, you can quickly and precisely sharpen all of your tools. SVD-185 gouge jig, SVS-50 multi jig, or SVD-110 tool rest: This set lets you attach any of these three jigs to your bench grinder. If you want, you can put it on either side of your grinder. Rubber feet make it more stable and lessen vibrations.

Sharpen a wide range of tools with ease.

With the BGM-100 bench grinder mounting set, you can attach a Tormek woodturning jig to your bench grinder and use it to sharpen almost any tool in your shop with the best precision possible. Gouge jigs: SVD-185, SVS-50, and SVD-110 (primarily for turning scrapers, hollowing tools, and thin parting tools).

Mounting a Jig on Your Bench Grinder has a lot of advantages.

It’s often faster to shape tools on a bench grinder than on a lathe. Even though the tool can be hard to control by hand, it can be easy to accidentally remove more steel than you need. To sharpen your tools quickly and precisely, attach a Tormek jig to your bench grinder with this mounting set. You can then control the process more precisely and get better results.

A simple and flexible installation.

You can put the BGM-100 on either side of your bench grinder, either on a wooden platform or directly on the bench. It’s up to you. Set: This set is meant for grinders with wheel diameters of between 6 and 10 inches. Wooden platform must be at least 3/4-inch thick. Using the rubber feet that come with your computer will make it run more smoothly and keep it steady.

People talk about Tormek.

There are many different types of edge tools, and Tormek wants to help you find the best way to sharpen them. It’s based on Swedish traditions of cutting-edge innovation, functionality, and quality. Tormek has come up with a unique sharpening system that has become the standard for modern edge tool sharpening.

Since 1973, Tormek has been very good at coming up with new ways to solve problems. This has led to 13 patents and the widest range of products on the market. It comes with 16 different jigs and attachments, each of which is designed to make it easier to get the best possible sharpness on all kinds of edge tools.

Today, Tormek exports to more than 30 countries around the world. The products are liked by cabinetmakers, carpenters, woodcarvers, and wood turners, as well as chefs who work in restaurants, industrial kitchens, and at home. Another common use for the Tormek system is in businesses that sharpen things for a livin.

Everything that goes into making products and building them is done in Sweden by Tormek. The company is in Lindesberg, a small town in the middle of Bergslagen, which is known for its history of mining. People who make the products work together closely. All of them are experts in their fields and the best. This ensures that the best and most up-to-date manufacturing technology will always be available.

What’s inside the box.

It comes with one universal support, one horizontal base, one height-adjustable block, hardware, four rubber feet, a set of profile labels, and a guide for how to use it.

There is a Manufacturer.

Mounting Kit for the Tormek Bench Grinde.

It was very easy to improve the accuracy and speed of my tool reshaping when I used the TOR-SE77 tool holder with the square edge tool. You need to take your time and practice with cheap blades in order to become good at it. The BGM100 takes a lot of time and thought to set up, so it gets 4 stars. The first time I tried it, I followed the directions to the letter. I set it up, but it was too close to the stone (I kept hitting my fingers on the Delta grinder’s quick release hub) and not really in the right place. Before setting it up a second time, I took my time. I set it up by feeling and figuring out how wide my widest blade will be. With the adjustable height, too, it worked. This was a lot better and safer. NOTE: There is a learning curve with these tools, so if you are new to sharpening and reshaping things (like I am), take your time and practice on something old or not very valuable. I think that if you can afford it, you should get a grinder that can be changed in speed. Good: Delta has a good one. They are also better than the cheap gray wheels that come with the grinder.