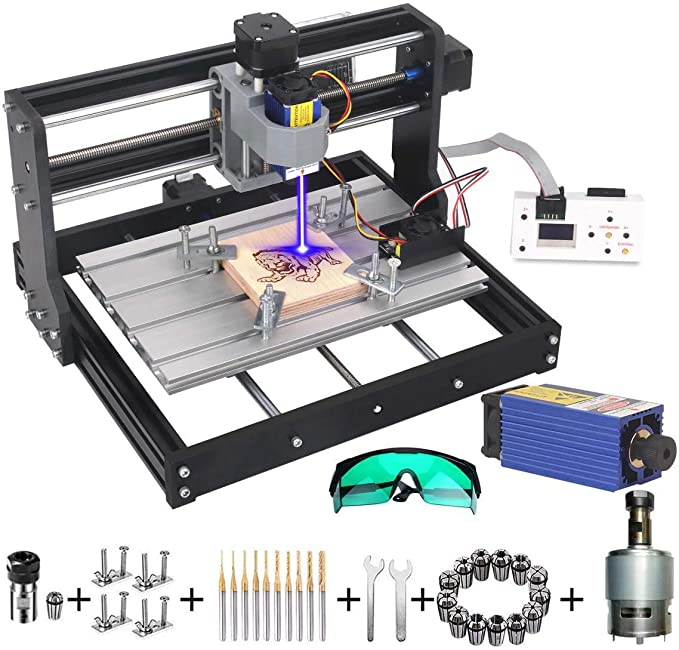

This is the new version of the 2-IN-1 CNC 3018 Pro. cnc 3018-PRO is a better version of the 3018 machine. GRBL is the control software. The working area is 30x18x4.5cm. The spindle has a motor of 775. (12-36V. In this case, 24V: 10,000 r / min. Windows XP, Windows 7, Windows 8, and Windows 10 are all supported. In this video, we show you how to make a plastic body with a profile, make it small, light, and use USB and GRBL control systems.

Ivory, leather and other materials that can be burned can be used with the 7W 7000mW module. It also comes with an adapter that lets you use the module with other devices. There are some things that can’t be used with this: metal, iron, glass, 201/304 stainless steel, jewelry, or silver.

It doesn’t need to be connected to a computer, and you don’t need to download files. Manually move the X, Y, and Z axis to where you want the engraving to start. Manually open or close the spindle, and manually open or close the cooling fan.

Versatile: The MYSWEETY can cut all kinds of plastics, woods, acrylics, PVCs, and PCBs. It can also be used on a wide range of projects and materials.

Assembly instructions are available, but if you get stuck, don’t hesitate to ask us for help with any questions that you might have about the process. Thanks.

Here is a little about me. Programming and operating CNC (Computer Numerical Control) machines has been a job I’ve done for more than 40 years now. A wide range of machines, from small 5-axis machines to machines that can move 50 feet long. I’ve written and published two CNC programming manuals that are used by big businesses to teach their employees how to do their jobs. So I’ve been around the neighborhood a few times.

Now. On to this pretty little machine. To cut plastic, I didn’t want to use a big CNC machining center. I came up with a unique project for myself. When I looked for a desktop CNC engraver/router on YouTube, I looked for a long time and saw a lot of videos about them. There are a lot of sellers to choose from, but there are only a few different options when it comes to the hardware and electronics that come with it. They all, like this one, have to be put together. No way could they sell these at this price point if they put them together and then had to figure out how they could ship them.

In the beginning, you should watch some videos. Then, take your time. A mindless movie was playing in the background, and I was holding my laptop next to me with the CD that came with the project. I spent 1.5 hours putting it together while I watched the movie.

When I looked at some of the reviews for this machine, and every other one, the screws that come with the table are too short. :-. This machine comes with M5x16 socket head cap screws. I also got a set of M5 screws that were 8mm to 20mm long in case I need them. These screws were put in place of the M5x12 screws that came with it. So that didn’t matter right away.

The CD came with the package. It has the instructions on how to put it together and all the software that comes with it. The instructions were easy to follow even though there were only a few words written on the paper. Take a look at the pictures and try to make it look the same in real life. There’s only one dimension that needs to be pretty close to perfect when you build it. You need to put 46.5MM (1.83″) from the back end of the side rails to put vertical legs in the right place. So, that was easy for me. I had a dial caliper with me. It doesn’t matter if you don’t have one. The distance isn’t as important as the fact that both legs have to be the same distance from the back end of the side rails. Use a tape measure and be as precise as you can be, but don’t be too precise. This is important because it affects how square the X axis of the machine is to the table, which affects how well the machine works. PLASTIC is not used for the front, back, or side uprights. They’re made of phenolic resin, which is hard and durable. It’s very durable, and this design makes it a lot easier and more accurate to put together than the other ones. In the end, the structure will be much more strong and will use fewer parts in the making process. As time goes on, there will be less to align and less to loosen up.

Then it was time to check and connect all the wires. This machine came with the CAMTOOL CNC V3.3 GRBL control board and the most up-to-date version of GRBL (Version 1.1). The board shows where everything goes. However, the spindle motor doesn’t say which wire is positive (Red wire) and which is negative (Black wire), so it’s hard to tell which is which (Black wire). So I just plugged the two together and looked at which way it turned when I turned it on. When you look at the spindle motor from the top, it should move in the opposite direction of the clock. Switch the red and black wires, like I did, and everything will work again. Because milling and drilling tools are made to move in the same direction, running them backwards won’t hurt them.

The offline controller was plugged in and given power when it was all wired up and ready to go. It worked out. The first time. It worked out for X, Y, and Z. When the motor started up and shut down, it did that again and again. Pretty cool. Because I know how to write manual GCODE programs, I quickly made up a demo program to show you how. It was put on a micro SD card. I moved it there. Send it: I put it in the controller that was offline and sent it. Huh. It went. Do what I told it to do. But, be careful with what you do. The machine moves in metric units by default. In this case, if you run a program that is in inches (G20) and then move the machine with the offline controller, the machine will do bad things. When you do a jog move, the controller will set itself to a 5mm step. If it’s still set to inches, it moves 5 inches. Keep the power cord close by, just in case you need to unplug it before it goes too far. Keep in mind that at the end of your GCODE program, make sure to switch back to metric (G21).

3 things.

The software you need to make a GCODE program.

software to send your GCODE code to the control software (Or the offline controller).

To make things move, software on the CNC control board reads the GCODES and turns them into moves.

GRBL V1.1 is the firmware that comes with this machine. It will help you translate the GCODE program that is on the controller board. That takes care of number 3 on the list of things you need.

There is software that comes with number 2 to send the GCODES to the controller, so that takes care of number 2. Candle is the name of the person who sends GCODE. The CD has it. There are other free (open source) GCODE senders out there, and you can find them by searching with Google. Do about the same thing. Wait for the machine to do it, then send another line until it is done. Candle also lets you move the machine by hand and set the X, Y, and Z points that tell the machine where to start.

The package doesn’t come with any software that you can use to make a GCODE program. There are a lot of programs that are free but hard to learn. Programs that cost a lot and are also very hard to learn are also out there. A lot of people find Easel very easy to learn. Free, too. In this case, it’s web-based. You can draw what you want and then export the Gcode file. You can keep it at home and send it through Candle. Or, it can be put on a microSD card and sent to the machine with the offline controller, so it can be used.

The offline controller can be a very good thing at the same time. It lets you run the machine without a computer. There must be no connection between a computer and the control board at the same time. Their information will be sent to the control through the same ports, which means they will fight with each other and neither will work. It’s either one or the other. Neither one. A good thing about the offline controller is that you won’t have to keep a laptop or desktop computer near something that can make a mess, like a game machine.

Make a drawing with an easel. Then, convert the drawing to GCODE. Send the GCODE to a Candle or Offline Controller. Turn the GCODE into movements with a control board with GRBL. The project is done.

Then you’re ready to cut something. The bits that come with this package may be good for engrave soft materials, but they’re not the best for other things. I think you should get some real endmills. The machine comes with an ER11 collet holder that is attached to the spindle motor, so you can use it. But it doesn’t come with a set of wrenches. Need a 13mm to hold the spindle and a 17mm to turn the nut that holds it in place. In this case, a few small adjustables will work. It does come with a 1/8″ collet, though. A 1/8″ collet can be used for a lot of different things. Most endmills that are less than 1/8″ in diameter have a shank that is 1/8″ long, so this collet will work with them, too. They come in sizes from 1mm to 7mm, or.04 inches to.275 inches in the United States. You might want to buy a set. There should be at least one for endmills with a 1/4″ shank, or els.

Over all, I think this machine is a great deal. None of these things will be able to be cut with it. The only thing it doesn’t work well with is hard materials like wood and plastic. It’s good at working with other “soft” materials like acrylics and other things. The noise level isn’t too high. Make sure you know that if you need more rigidity or better accuracy, you’ll likely have to pay at least twice as much for a base model from anywhere else. Add to it to make it like this machine.

If you bought a second one of these, the short socket head cap screw issue is now solved. All the screws are in place now. Weavers for the spindle collet holder came with the new machine as well.

There’s no reason to be surprised if your expectations are based on what is possible. Then, look for GRB. Find some YouTube videos about how to put things together. Read a little. It’s a lot of fun to get the clamps off, blow off the chips or dust, and show off something you’ve worked on.

Before you do anything, I hope you know that this thing is just like a fishing pole. There are more things you need to fish with it. There are things like lures, line, and a cool hat. There is also a net, waders, and a boat and trailer..