“John, it is nearly impossible for a system to have no leaks. You should be commended for having a system so tight that the air compressor only cycles on about once a week.” “NFPA 13 under Dry Pipe and Double Interlock Preaction Systems Air Test, section 24.2.2.1 states that 1.5 psi pressure loss per 24 hour period is acceptable. We recommend that a compressor cycle no more than 4 times per hour to ensure maximum compressor life, so you are in very good shape with your system.” If you have questions regarding our fire protection air compressors, their installation, best practices or troubleshooting please feel free to call or email us with them.

Simply put, an air compressor duty cycle is the amount of time a compressor will deliver pressurized air within a total cycle time. If an air compressor has a 50% duty cycle, the compressor can provide air power for half of its total cycle time. If an air compressor has a duty cycle of 100%, the compressor will deliver pressurized air for the entirety of its cycle time.

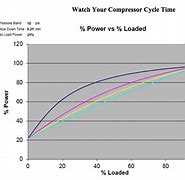

If you have a lubricated screw compressor running in load/unload mode, you should be aware that the compressor cycle times greatly affect the efficiency of your compressed air system. The cycle time is the amount of time it takes for the compressor to load and unload while supplying your compressed air needs. The width of the compressor pressure band also affects cycle time; widening the pressure band from 10 psi to 20 will reduce cycle time by half.

Storage volume must be installed directly between a reciprocating compressor and the connected rotary screw and centrifugal compressors to prevent the reciprocating compressor’s pulsations from damaging the other units. The efficiency of partly-loaded lubricated rotary screw compressors operating in the load/unload mode improves as the storage volume increases. One often hears that VSD compressors aren’t damaged by short cycling, don’t need storage and produce air instantaneously upon starting.

On the face of it, buying an air compressor seems fairly simple – just match the pressure and flow requirements and bingo, you’ll find the right compressor. Put simply, duty cycle is the percentage of time that a compressor can run versus how long it needs to rest before it can start compressing air again. Failure to adhere to the run time and duty cycle of a compressor – the two key pieces of information – can lead to overheating and damage to the motor.

The problem with the duty cycle of an air compressor is, that unlike many other standards in the compressed air industry, there is not an official definition for the duty cycle of an air compressor. Air Compressor Duty Cycle Relationship With CFM. CFM ratings on air compressors are another very important rating to look for when selecting an air compressor, along with the duty cycle. CFM ratings tend to be based on the output of the air compressor pump, and it’s even more important to understand the relationship between the duty cycle and CFM. In order to understand the compressor’s CFM capabilities to deliver continuously as opposed to intermittently, you must multiply the CFM rating of the compressor by the duty cycle percentage.

air compressor cycle times Related Question:

What is a good duty cycle for a compressor?

A 100% duty cycle will generally be one of the requirements for any air compressor used in a factory setting. In most cases, duty cycles are performed at 100 pounds per square inch (psi) in moderate temperatures in the lower 70s, typically 72 degrees Fahrenheit.

How long should a compressor run?

It is typical for a refrigerator compressor to run anywhere between 4 to 8 hours straight before shutting off. In fact, newer refrigerators are expected to constantly run 80-90 percent of their lifetime.

How long can an air compressor run continuously?

How long can you leave a compressor running? Depending on the size and type of compressor, air compressors can be left running anywhere from a few hours to 24 hours a day, seven days a week.

What is a 100% duty cycle?

A 100% duty cycle simply means the compressor will deliver a consistent CFM and PSI the entire time the compressor is in use, which is different than being able to run continuously.

Should an air compressor run all the time?

If you have multiple compressors, your system should be set up so as not to allow constant operation. For screw compressors, the cooling systems are much better, so the compressors can run constantly with no issues. But running constantly usually means the units are not very efficient.

How often should central air cycle on and off?

In mild weather, a correctly sized and functioning AC will run in cycles of about fifteen minutes each. This is approximately two to three times per hour. If your air conditioner runs for less than ten minutes at a time instead, then it’s probably oversized—too big for your home.

How long should Central air run at a time?

Under ideal operating conditions, AC units should run for about 15 to 20 minutes before shutting back off. In mild weather, the cycles might be a bit shorter than this. Keep in mind that running for less than 10 minutes isn’t ideal because the air conditioner can’t dehumidify properly.

How many hours will a compressor last?

On the other hand, rotary screw compressors have an average lifespan of between 35,000 and 40,000 hours. They run at high speeds and tend to be very loud, so they should be kept in a dedicated compressor room when in use.

Can you use an air compressor while its running?

If your operation needs it, they can run 24/7, but like a piston unit they run when a pressure signal turns them on. Unlike most piston compressors, most rotary compressors idle before they shut down completely.

What does 40% duty cycle mean?

Duty cycle is the amount of time it may be operated at a given output without exceeding the temperature limits of its components, and it is measured using a 10-minute cycle. In our example, the welding machine has a duty cycle of 40% at when MIG welding at 285 amps/28 volts.

Can duty cycle be more than 100?

The duty factor for periodic signal expresses the same notion, but is usually scaled to a maximum of one rather than 100%.

How many RPM should an air compressor run?

The sort of industry standard of 800-900 rpm is for a motor matched to the max hp rating of the pump. If the pump cant do the work of a 3hp motor then you can slow down the motor which will extend pump life as well as cut down heat.

How many times should my AC cycle per hour?

Ideally, a properly operating air conditioner should cycle for roughly 15 to 20 minutes, two to three times per hour. If the temperature inside your home is very high, is much higher than the temperature that your thermostat is set at, or the outside temperature is very high, the run time will increase.

Is it OK for central air to run continuously?

An undersized system struggles to cool your home, which is why it’s running constantly. This constant running will reduce pressure in the evaporator (cooling) coil until it freezes over. This is dangerous because the freezing can cause liquid refrigerant to flood back to the compressor and damage it.

Why does my AC come on every 5 minutes?

An AC system may turn on and off repeatedly due to dirty, broken, or failing parts or for various other mechanical or electrical reasons. The term short cycling refers to when an AC system’s cooling cycle terminates prematurely only to turn on again after a short time.