Using Angle Grinders to Cut Metal is one the most convenient ways of metal fabrication as angle grinders are a metalworker’s right hand; You can tackle a wide range of metalworking operations with the right angle grinder equipment and accessories while staying safe on the job. Now that we’ve established the notion of using an Angle Grinders to Cut Metal, let’s examine what the optimum way of operating an angle grinder to cut metal. Having a strong an Angle Grinders to Cut Metal and other difficult materials is a huge benefit for a professional metal worker who conducts a lot of grinding and metal fabrication operations.

Get the most out of your angle grinder by using different types of angle grinder wheels. The most apparent disc and probably the most popular one among different types of angle grinder discs is the grinding disc. Similar to other angle grinder discs, wire wheels are produced in different shapes and sizes because they are used for different purposes.

DIY users approaching projects in the metal fabrication field, where steel cutting is required, always have an initial question on what is the best abrasive product to efficiently cut through both stainless steel and mild steel. A bench mounted, drop saw will fit a 14″ 350mm or 16″ 400mm cutting blade, and this is most suitable for heavier steel work as the chop saw can cut through almost any metal with the correct cutting blade. As stainless steel is one of the harder types of steel to cut, a disc that cuts through stainless steel will cut through all types of metal including aluminium, sheet metal, rebar and other mild steels.

angle grinder metal cutting disc Related Question:

Can you use an angle grinder to cut metal?

An angle grinder is a power tool that can be used for different projects. You can cut metal, aluminium, concrete, bricks, pavers, wood, and other dense materials; you can sand and polish different surfaces to sharpen tools and grind materials.

What kind of disc do you use to cut metal with an angle grinder?

But let’s pretend you’re using a 4-1/2-inch grinder with a flat diamond cutoff blade to cut stainless or mild steel, as most people do. A 1mm or 1.6mm iron-free disc should be used to cut the stainless steel. When cutting thin metal materials like sheet metal, a 1.0mm or 0.8mm cutting disc is recommended.

What disc do I need to cut metal?

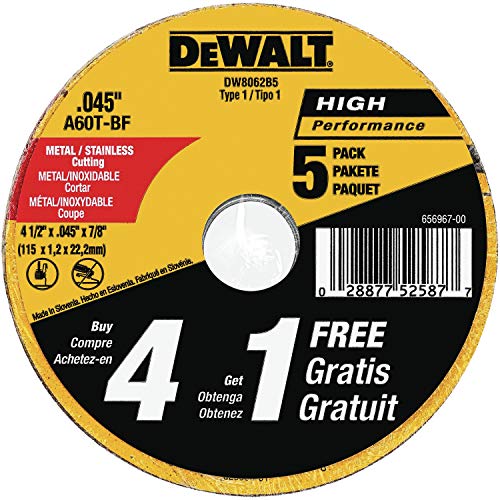

For standard everyday jobs on either stainless or mild steel using an angle grinder, choose a 1mm or 1.6mm thickness in your disc. For projects that involve thin metal such as sheet metal, choose a 1.0mm or 0.8mm thinner cutting disc.

How thick should a metal cutting disc be?

For standard, everyday jobs on stainless or mild steel, opt for a 1mm or 1.6mm disc thickness. For cutting thin sheet metals, choose a 1mm or 0.8mm disc. The beauty of these thinner discs is that they will cut through sheet metal faster, reducing clean-up work.

What can an angle grinder not cut?

The inspiration behind this creation is the natural defense mechanisms used by shells, grapefruit skins, and fish scales that makes them resistant from the attacks of various sea creatures. The material, named Proteus, cannot be cut using either angle grinders, drills, or high-pressure water jets.

What is the difference between a cutting disc and a grinding disc?

Clue is in the title, a cutting disc is thin and used for cutting and a grinding disc is much thicker and used for grinding not cutting.

What are INOX cutting discs?

INOX means stainless steel cutting disc. INOX cutting disc means that the cutting wheel does not contain iron and therefore has the ability to cut stainless steel and mild steel.

Can you use a masonry blade to cut metal?

We recommend using a diamond blade that’s labeled as a ferrous-metal-cutting blade, but many tradespeople use a regular masonry diamond blade with good results.

Can I use a stone cutting disc on metal?

Stone cutting discs will actually cut metal but they will tend to tear up and fall apart as they chop their way through and due to this the flying debris can cause a great deal of harm and damage to yourself, others around you and also to any nearby objects.

Can I put a metal cutting blade on my miter saw?

Although mitre saws were traditionally used for cutting wood, with the correct blade they can make light work of cutting through steel and aluminium profiles at an angle.

What size are angle grinder discs?

The two most common disc sizes are 4.5” (115mm) and 9” (230mm). Grinders with larger discs are particularly well suited to heavy-duty applications, whereas those with smaller discs are ideal for finer work.

What are thick grinding discs for?

Grinding discs are perfect for use on metal or stone. One side of the metal disc is finished with abrasive grains which can be used to grind off rust or paint. Grinding discs can also be employed in the preparation of stone and metal surfaces.

What kind of metal Cannot be cut?

Researchers claim the material, known as Proteus, cannot be cut. In fact, it’s so tough it destroys any tool that attempts to slice into it.

What metal Cannot be cut?

Tungsten carbide rings are made of the hardest metal on earth. This is what gives it its scratch resistance, but this durability also means these rings resist cutting tools. Because these rings are so strong, many people worry about whether or not they can be cut off in case of emergencies like finger swelling.

What material stops an angle grinder?

Instead, this Ferosafe stuff is a graphene composite material specifically designed to resist angle grinders and drills, and it’s made by a British materials manufacturer called Tenmat who have partnered up with Hiplok. Essentially this stuff disintegrates angle grinder blades!