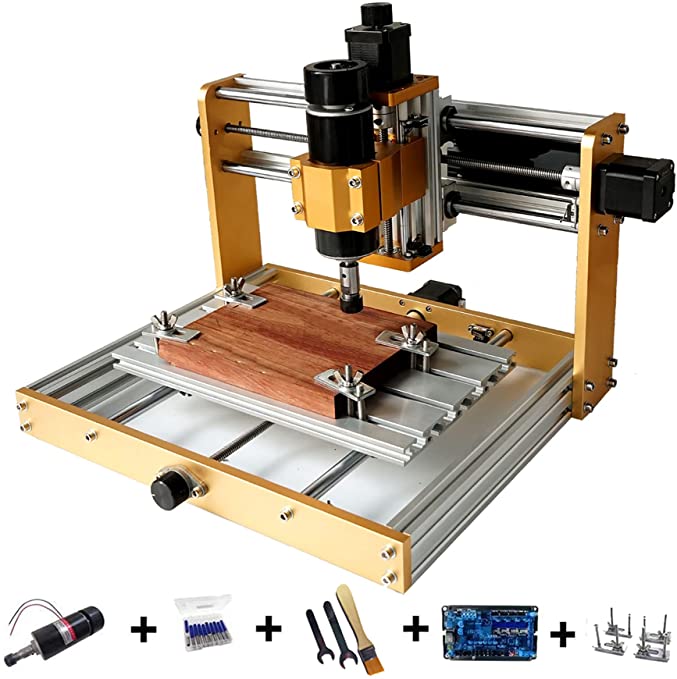

Convenient to use: The straightforward yet durable design allows you to assemble the unit in less than 30 minutes right out of the box. Beginners and wood carving machine enthusiasts alike will benefit from this entry-level CNC engraving machine, which can provide valuable experience.

Strong and stable aluminum alloy construction: The 3018plus body is entirely constructed of aluminum alloy, which is stronger and more stable. The spindle is powered by a 500W motor, as opposed to a 775W motor, which allows you to engrave and cut through more materials and open up more possibilities for you.

Grbl v1.1 is an open-source library that is compatible with all engraving machine control software that is based on the same version of GRBL. We support Windows XP, Windows 7, Windows 8, and Windows 10, and we provide software instructions on a USB flash drive. Assembly instructions are included in the package.

Because the ER11 chuck is designed with a negative differential design, it is easier to install after heating, which is important for the user’s safety when using it. Leave a square slot of 40*40mm in the Z axis to be compatible with the laser engraving module, which has a 52mm diameter.

Pre-drilled holes for the safety limit and emergency stop switch have been pre-installed in the machine body in order to provide you with a more enjoyable CNC experience. It is equipped with holes compatible with Nema17/23 42/57hs stepper motors at the top of the Z-axis for easy installation. Customer service is available online 24 hours a day, seven days a week to answer your questions and resolve your problems.

I just got my package today. I’ll make an attempt to put it together tomorrow and update the review as I go. I’ve unpacked the box and everything appears to be of high quality to me.

It is written on the stepper motors that they are manufactured by Lunyee Industries and are labeled 42BYGH48H-A-18D, KH 2021 03 20. This was referred to as a “strong Nema 17” on one website. I believe the 48 refers to the length of the item, which is 48 mm.

09/13/2.

I’ve finished putting the machine together to a large extent.

Observations.

1) The spindle motor was shorter than the 100v 500W motors advertised on Amazon, but I was able to find versions on a popular Chinese website for a 48v 500W motor that had dimensions that were exactly the same as the spindle motor. Because the collet holder and the motor shaft are so tightly coupled, I have not been able to put it all together. I’ve sent a question to the seller.

In addition, the long M4 screws that were used to attach the spindle assembly to the frame were a few hundredths of an inch too long, and the screws bottomed out on the aluminum mounting extrusions before they could be fully tightened. I was able to resolve this issue by utilizing some of the m5 washers that were provided. In the meantime, I had run out of washers for some of the less important areas.

3) The emergency stop switch that had been promised did not appear in my kit.

09/14/2.

It took a lot of effort to put this thing together. I’ve received a response from the seller. He is going to give me a $10 credit to use toward the purchase of an emergency stop button. In addition, he suggests that I use heat and a hammer to try to get the collet to fit onto the spindle, which I will do. However, as you can see in the picture, it did not work. The part reached approximately 300 degrees Fahrenheit (according to my thermal camera), but I was unable to remove or attach the collet any further with a heat gun or any other means. Right now, it measures approximately 1/4 inch on (ideally, it should measure 3/4 inch). The motor appears to be running smoothly, so it is possible that everything is fine.

Having now successfully connected my router to my computer candle program, I am able to move the cutter around on the table, as well as up and down, as well as turn on the spindle. Take a look at the photos of the completed assembly. The motor is mounted as low as possible, but because of the collet mounting issue, the motor may still appear to be a little higher than it should be. I’m going to try to mill something tomorrow.

09/17/2.

I’ve finished milling a “spoil board” out of MDF, following the instructions in YouTube videos and download files. Once everything was properly set up, the cutting process went smoothly (there is quite a learning curve). The result was less than ideal because the flat cutter left a series of saw tooth ridges on the surface of the wood. According to my findings, the problem was caused by the spindle axis not being perpendicular to the cutting table – as illustrated in the picture. There does not appear to be a way to compensate for this. This would not be a problem for the majority of jobs.

For the time being, I will maintain my three-star rating. if the collet were to be completely mounted on the spindle motor and if the spindle axis was perpendicular, I would give it a five-star rating. For the time being, the first issue is not a concern, but I believe there is a possibility that it will cause problems in the future. If I ever have the opportunity to cut more difficult materials, such as plexiglass or aluminum, I will try to update this review.

10/2/2.

The seller has sent a procedure for adjusting the z axis so that it is perpendicular, and it has been successful. As a result, I’ve raised my rating to four stars overall.