A bandsaw will make many cuts with precision and speed-when equipped with the right blade for the application. Bandsaw blades differ in thickness, width, length, and tooth configuration. Every time you change from one bandsaw blade width to another, you have to reset the saw’s tracking, tension, and blade guides.

Here’s some insights on how to rip boards on your band saw. A band saw can shape curves, saw rough lumber safely, cut joinery, and even rip boards to width. Most woodworking plans mention using a table saw for ripping boards.

Our famous Wood Slicer bandsaw blade cuts smoother and quieter than any other resawing blade on the market. Since noise intensity is halved with each 3dB decrease in sound level, our Wood Slicer Bandsaw Blades will subject your ears to no more than 1/4 of the sound intensity of the noisier blade, and at best can reduce noise intensity to less than 1/16 of what you might usually endure. Unless you’re actually fond of listening to a bandsaw blade scream though thick stock, our blade design will be the best you’ve ever heard on your bandsaw.

We manufacture carving blocks out of basswood and we were having trouble ripping thicker stock on our table saw. We invested in a 3hp bandsaw and we are looking for carbide tipped blades that would be good for ripping and also for making smooth cross cuts. “Be advised, though: Carbide-tipped blades require A LOT of frame strength on the part of the machine in order to get them cutting straight. Not sure what bandsaw you have but there are a lot more bandsaws that won’t tension a 1.0” carbide properly, than will.

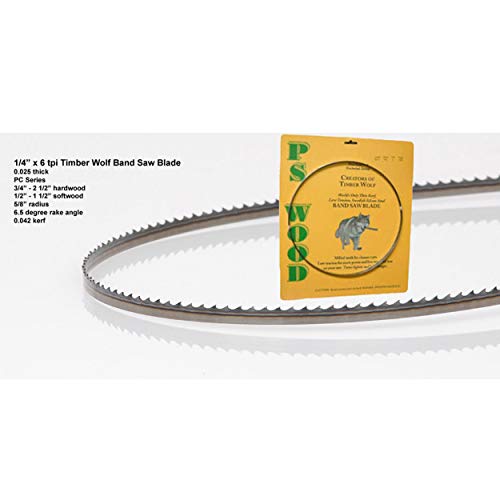

1/2″ x 2/3VPC Series Timber Wolf® band saw blades. 1/2″ x 4PC Series Timber Wolf® band saw blades. 1/2″ x 6PC Series Timber Wolf® band saw blades.

Having the best blade for resawing is crucial if you want the best outcomes. We wanted to put resawing blades in the spotlight, to give you the lowdown on exactly which bandsaw blades are the best. Choosing the best bandsaw blade for resawing presents so many options.

bandsaw blade for ripping Related Question:

What blade should be used for ripping?

Best Blade for Ripping Hardwood. The best saw blade for ripping hardwood is a rip blade. This blade is specially made for cutting through wood fibers, so it will cut through hardwood easily and leave a clean edge.

Can you rip cut with a bandsaw?

A band saw can shape curves, saw rough lumber safely, cut joinery, and even rip boards to width.

Which circular saw blade tooth pattern is best used for ripping?

Flat-top teeth are used on blades for ripping hard and soft woods. Because wood is much less likely to chip and splinter when it is being cut with the grain, a rip blade is designed to quickly and efficiently remove material.

What blade is best for resawing?

Resawing involves making rip cuts in the face of a wide board. So just like you would on the table saw, you’ll want to select a blade with fewer teeth per inch (TPI) than the blades you use for crosscutting or cutting curves. For most 14″ band saws, a 1 ⁄ 2 “-wide blade with 2-3 TPI is a good choice.

How many teeth blade for ripping?

Ripping: 10-inch blades with 24-30 teeth and 12-inch blades with 40 or fewer teeth. Crosscutting: 10-inch blades with 60 teeth and 12-inch with 80 teeth.

Can a cross cut blade be used for ripping?

The Crosscut blade is used when cutting short grain, while the Ripping blade is for long grain. The Combination blade allows one to cut both crosscut and ripping using the same blade.

Will a bandsaw cut 2×4?

your “small” tablesaw is one of the finest in the portable table saw category and should have no problems resawing a 2×4 although you may want to finish the cut with a jig saw by setting the blade slightly less than half the thickness of the 2×4.

Is more teeth on a saw blade better?

The number of teeth on the blade helps determine the speed, type and finish of the cut. Blades with fewer teeth cut faster, but those with more teeth create a finer finish.

What blade is best for cutting plywood?

For this type of plywood we recommend moving up to an 80 tooth blade, or even a 96 tooth blade with a carbide tip. These are designed just for sheet goods and do a much better job than either the 40 tooth or the 60 tooth. The 80 or 96 tooth blade takes smaller cuts so always a better finish.

How many teeth do you need for plywood?

To get the best-quality cuts, invest in an 80-tooth blade designed for sheet goods. The small teeth take little bites to reduce chip-out and are steeply beveled at their edges to score the veneer face. You’ll have to slow your feed rate, but will get a much smoother edge.

How thick can a bandsaw cut?

Band saws are the undisputed champ when it comes to cutting curves and slicing through thick material. Many small band saws can slice though lumber a full four inches thick, and bigger saws handle six-inch cuts.

What size bandsaw do I need for resawing?

To get started with resawing, I recommend a band saw of sufficient power and with a large depth of cut. Any motor smaller than 1hp and depth of cut less than 10″ will limit your effectiveness. (Some 14″ band saws have about a 6″ maximum cutso you’d be limited to a 12″ wide book-matched panel or less.)

How much does a miter saw cost?

A basic compound miter saw starts at $100, while miter saws with sliding blades start at $125. Dual-bevel miter saws start at $200, and professional-level miter saws with special features can cost as much as $800.

Can you put a 12-inch blade on a 10-inch table saw?

The Blade Runner Twelve-inch blades are harder to find, and at a higher price typically at woodworking supply retailers. Theoretically, a 10-inch blade will fit on a 12-inch table saw, but the arbor — or hole in the middle of the blade — is typically smaller.

What is a 24-tooth blade used for?

For most construction work, a 24-tooth general use blade is sufficient. That blade is very aggressive and will help you rip and cross-cut lumber and sheet goods quickly and with a high degree of accuracy. With a 24-tooth demo blade, you’re getting work done quickly, but you won’t get a near-finished edge.