Accura has always been among our top choices because they have been making these guides for a long time and in that time, they have mastered the craft of making guides. This model sports a premium build and has three bandsaw guide bearings. The main job of the guide is to ‘guide’ the blade so that it stays perpendicular.

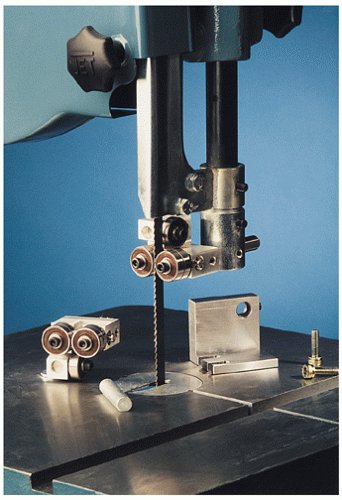

Although Iturra does not recommend using its Band Rollers with blades less than 1⁄8 “, I tested mine with 1⁄8 “, 1⁄4 “, and 1⁄2 ” blades, cutting thick stock and making tight-radius cuts to force the blade against the bearings. These bearing guides showed no signs of wear, a big upgrade from my square-block graphite guides. When cutting arcs and circular shapes-and especially in resawing-the bearings proved much better than my old graphite guides at holding the blade perpendicular to the workpiece with no twisting or deflection.

Bridgewood 18″ Band Saw Guide Upgrade KitBecause of manufacturers variations in the saw, the Bridgewood 18″ saw has two kit options. This provides your saw with reduced blade friction, improved cutting accuracy, and is adjustable for blade widths from 3/16″ to 1 1/4″. P C GAKIT BUF14.”Buffalo14″Buffalo Saw Guide Conversion KitBuffalo Band Saw Aftermarket Parts.”14″ Buffalo Band Saw Guide Conversion kit. “Delta 14″ Hex Micro-Adjust Guide Kit.The Delta 14″ Hex Micro-Adjust upgrade kit updates your saws performance through the use of Tool-Less Micro-Adjustable guides and is for use with Delta 14” saws that have a hexagonal upper guide post.

“The cheap blade guides from my 14” bandsaw were the easiest to adjust. The homemade guides work just as well, and, surprisingly, aren’t any more annoying to adjust than the fancy aftermarket blade guides or the big guides that Ted sent me. A properly adjusted set of blade guides will guide the blade perfectly well, and a fancy aftermarket guides don’t improve on that.

02-11-2013, 8:46 AM #1 Best bandsaw guides I am going to change the guides on mu Grizzly G555LX band saw. Without being able to look, I don’t know if your lower guide and thrust bearing is the same design as a Jet, or a Delta 14″.The Delta guides are closer to the underside of the table than a Jet and are oriented differently. I changed my Grizzly G0555P bandsaw guides to cool blocks.

best aftermarket bandsaw guides Related Question:

How high should the guide be on a band saw?

Make sure the wheels and blade are in good condition. Make sure the blade is positioned properly on the track. Adjust blade guard height to about 3 mm or 1/8 inch to 6mm or 1/4 inch above the top of the material being cut. Wider gaps will place tension on the blade and increase the risk of breaking.

What is the number 1 safety rule of the band saw?

Safety Rules Safety glasses are required. Never clear small pieces while blade is moving. Never adjust saw or setup while saw is running. Never cross arms.

Which way should the teeth face on a bandsaw?

On a typical wood or metal cutting blade the hook or of point of the blade should be pointing down for a vertical blade bandsaw, or for a horizontal blade saw the hook of the teeth should be pointed such that they enter the workpiece first as the blade moves.

What is a blade guide?

6Oct by Lori Balkus. Bandsaw blade guides keep the bandsaw blade on track while cutting through materials. Blade guides should be set above and below the saw table to help reduce vibration by holding the bandsaw blade in place while cutting. This assures a precise and quality cut.

How many teeth does a bandsaw blade have?

The general rule of thumb is: For wood and soft materials aim for 3 – 6 teeth in the workpiece. For metals and harder materials aim for 6 – 24 teeth in the workpiece.

How tight should my bandsaw blade be?

The blade should deflect no more than 1/4 in. A good place to begin is to tension the blade until the meter reads proper tension for the next wider blade. For example, if you’re tensioning a 3/8-in.

Why can’t I cut a straight line with my bandsaw?

Band Saw: Why won’t my band saw cut straight? When the band saw cuts crooked, a dull blade, improper feeding, loose blade tension or not using a work piece guide could be the cause. Use the rip fence or miter gauge to guide the work piece uniformly through the cutting blade to make straight cuts.

What does resaw mean on a bandsaw?

A resaw is a large band saw optimized for cutting timber along the grain to reduce larger sections into smaller sections or veneers. Resawing veneers requires a wide blade – commonly 2 to 3 inches (52–78 mm) – with a small kerf to minimize waste.

Can you rip wood on a bandsaw?

A band saw can shape curves, saw rough lumber safely, cut joinery, and even rip boards to width.

Which side of the line should you always make cuts on?

Always cut to the outside of your mark line because you will have to round off your edges regardless. For thinner wood, a jigsaw can provide better results.

Can a bandsaw blade be turned inside out?

Re: Turning a band blade inside out hi ,just get heavy gloves,an uncoiled blade ,step on the bottom and turn the blade inside out,and it will go right on a turner mill and just reverse the blade to sharpen. Thanks.

What is a skip tooth band saw blade?

Skip tooth blades have widely spaced teeth at a 0 degree rake angle to prevent clogging when cutting soft wood, non-ferrous metals and plastics. Hook tooth blades have a deeper gullet—that is, larger teeth—and a positive 10 degree rake angle. This helps the blade to feed into the material more aggressively.

What are the different types of circular saw blades?

Blade Types: Generally speaking there are four major categories of circular saw blades. They are: Rip Blades, Crosscut, Combination and Specialty blades. Ripping saw blades are designed primarily to achieve a smooth, clean and safe cut when ripping wood or cutting in the same direction as the wood grain.