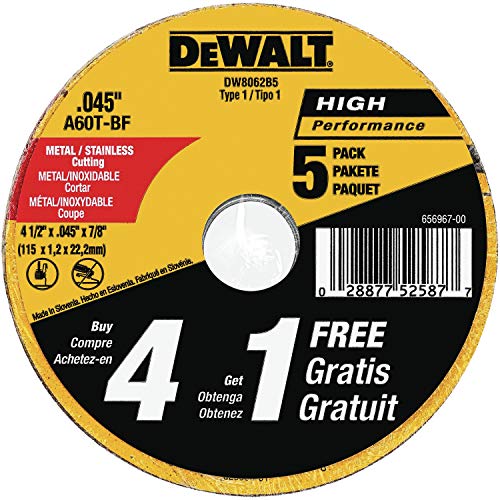

Now there is 2 Wheel Types, the first is Type 1 where the wheel is flat and used primarily for cutting see image below. The only exception for non-ferrous metals with Aluminum Oxide would be copper we would recommend a 36 grit cut off wheel. If your not on a budget and performance is a must a ceramic cut off wheel well surely impress.

You should choose the best angle grinder wheel for cutting metal to maintain your performance and protect you from unwanted injuries and accidents. To reduce metal fabrication costs, you need to choose a sturdy cutting wheel to handle your metal cutting work. I have completed the detailed reviews on the best angle grinder wheel for cutting metal.

DIY users approaching projects in the metal fabrication field, where steel cutting is required, always have an initial question on what is the best abrasive product to efficiently cut through both stainless steel and mild steel. A bench mounted, drop saw will fit a 14″ 350mm or 16″ 400mm cutting blade, and this is most suitable for heavier steel work as the chop saw can cut through almost any metal with the correct cutting blade. As stainless steel is one of the harder types of steel to cut, a disc that cuts through stainless steel will cut through all types of metal including aluminium, sheet metal, rebar and other mild steels.

Get the most out of your angle grinder by using different types of angle grinder wheels. The most apparent disc and probably the most popular one among different types of angle grinder discs is the grinding disc. Similar to other angle grinder discs, wire wheels are produced in different shapes and sizes because they are used for different purposes.

best angle grinder cut off wheel Related Question:

What’s the best cut off wheel for angle grinder?

045 wheels are the best choice for efficient cutting. They should never be used for deburring metal after cutting or grinding. This type of misuse could result in wheel failure resulting in severe injury.

Can you use an angle grinder with a cutoff wheel?

NEVER attach a Type 1 straight or cut-off wheel to this angle grinder. Use for any other purpose is not recommended and creates a hazard, which will result in serious injury.

How do I choose a cut off wheel?

CUTTING WHEEL DIAMETER A wheel’s RPM rating tends to correspond with its diameter and the tool it is designed for. Common cutting wheel diameters range from 2 to 4 inches for die grinders, 4 to 9 inches for angle grinders, and 12 to 20 inches for chop, stationary, or high-speed saws.

How thick of metal can a cut off wheel cut?

Resinoid-bonded abrasive cutting wheels are available in various sizes and thicknesses. The most popular range is 2 to 16 inches in diameter, and common thicknesses are from 0.045 in. to 1⁄8 in. Thinner wheels remove less material during the cut.

What is the difference between Type 1 and Type 27 cutting wheels?

The Type 27 Cut Off Wheel must be used with an appropriate guard and a depressed center back flange. The center hub protects the user from cutting too deeply. The hub also allows for avoiding reinforcement wear and for extra rigidity for additional safety. The Type 27 produces 20% less cuts than the Type 1 on average.

What size cutting disc do I need?

The size of the disc should have a direct bearing on your choice of angle grinder. The two most common disc sizes are 4.5” (115mm) and 9” (230mm). Grinders with larger discs are particularly well suited to heavy-duty applications, whereas those with smaller discs are ideal for finer work.

What grit is best for cutting metal?

If you are going to be cutting ferrous metals such as welds, steel and Iron. You can use your most common abrasive grain which is Aluminum Oxide and any grit range should suffice for these metals. Aluminum oxide cut-off wheel with 60 and 46 grit are ideal for sheet metal with minimum burring.

What is the cutting thickness for an 18cm disc and what can you cut with it?

The 18cm discs can be used for small pieces of wood, thin metal and aluminium, which are 4-5cm thick. The 23 cm discs can cut larger pieces of any material that is 7-8cm thick.

Is a cut off tool the same as an angle grinder?

A cut off tool can only be used for cutting, whereas an angle grinder provides you with cutting, shaping, sharpening, grinding, and other functions. A cut off tool can be easily operated with one hand, while the angle grinder requires both hands.

Can you use a grinding disc to cut?

Do not attempt to cut with a grinding disc or grind with a cutting disc. Each disc should be labeled either “Stone” or “Metal”. The material you work on should only be cut or ground with the disc labeled for that material.

Which bond is used in cut off wheels?

Rubber bonded (R) wheels: For making flexible wheels. Operates at high speeds up to 16000 ft/mm. They are commonly used for snagging work in foundries & for thin cut off wheels.

What are cut off wheels used for?

As the name would suggest, cut-off wheels are made to cut things off. Be it a stubborn bolt, nail, separating a weld that is no longer needed, or simply needs to be separated and redone. In short, cut-off wheels are used to change the shape of metal. Either to cut it off, or to cut out portions of it.

What is the difference between a cutting disc and a grinding disc?

Clue is in the title, a cutting disc is thin and used for cutting and a grinding disc is much thicker and used for grinding not cutting.

What are thick grinding discs for?

Grinding discs are perfect for use on metal or stone. One side of the metal disc is finished with abrasive grains which can be used to grind off rust or paint. Grinding discs can also be employed in the preparation of stone and metal surfaces.

What is INOX cutting disc?

INOX means stainless steel cutting disc. INOX cutting disc means that the cutting wheel does not contain iron and therefore has the ability to cut stainless steel and mild steel.