Kind of like a hollow ground knife blade vs. a concave grind knife blade. Over 90% of my sawing Pine and Red Oak is while using 1″X.045X10 blades. Does that mean that I am right. Certainly not. I run one blade for everything. It’s easy to get tangled up in the blade jungle. Sure, some blades may be more adapted to certain uses, but that does not mean that others will not do the job. Knotty Pine, White Oak, & Hickory favor 4 blades. Over 90% of my sawing Pine and Red Oak is while using 1″X.045X10 blades. Several days ago I cut into a cherry logthat has been down at least 3 years +, it cut well until the blade took a nosedive halfway though and the blade and came off the wheels and jammed.

Here is a helpful guide to understanding different parts of a band sawmill blade and how to choose the best blade profile and material for your sawing application. “E. Tooth Set is the distance the tooth is bent beyond the body or raker tooth of the blade. Tooth set clears a path in the wood for the body of the blade which is measured by kerf or the total amount of wood removed by the blade with each pass. Wood-Mizer thin kerf blades remove less than 1/10” which produces about 20% more boards per log than circle mills or chainsaws. With hundreds of combinations based on profile and material, every Wood-Mizer sawmill blade tooth is precisely set by computer-controlled equipment and completely profile ground tip to tip using super abrasive grinding technology to ensure the highest quality blade performance.

Sawmill range will help you unleash the true potential of your sawmill. Sawmill bandsaw blades is not only ground, using computer-controlled machinery for exceptional cutting performance, but also deep hardened to allow for up to 100% more regrinds per blade than the competition, that’s twice the life. Speak to a member of our helpful team today on +44 1977 705 600 to learn more about how our sawmill bandsaw blades can transform your cutting.

According to the blade manufacture’s they all make the best blade. If you are really serious about the best blade and price is secondary, then go with a carbide tipped blade like the Starrett Advanz carbide tipped blade. As eddiemac said stay with just a few blades the same and you life will be much happier.

Before selecting a blade for an industrial sawmill, it helps to know the different blade parts and how they function. Blade width: Blade width refers to the distance between the body of the blade and the tip of the teeth. Call us at York Saw and Knife Co, Inc., and we’ll help you select the right blade for your needs, or custom-make a blade to meet your specifications.

Lubrication, alignment, blade quality, and other factors that affect how long a bandmill blade will stay sharp in heavy use. Two hours is a good run life for a blade in hardwood, and can drop to one depending on how your blades are resharpened. 025 depending on blade width and thickness, also check the blade flatness.

best bandsaw mill blade for hardwood Related Question:

What is the best blade for a sawmill?

9° Sawmill Blades – Ideal blade for lower horsepower (24HP and below) sawing frozen wood, hardwood, and small diameter logs. 10° Sawmill Blades – Very popular all-purpose blade for sawing mixed hardwoods such as red oak, cherry, walnut, soft maple, and poplar.

How do I choose a band saw blade for wood?

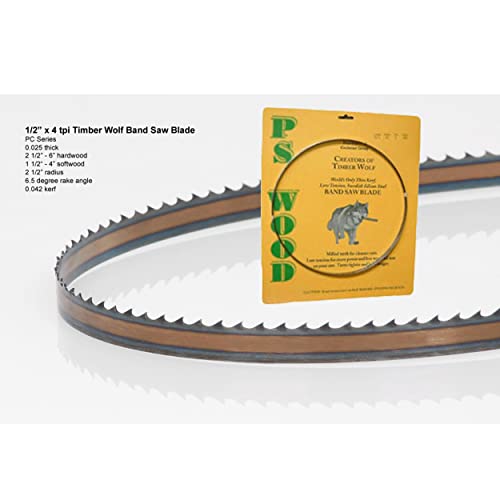

Use coarse tooth blades (2 or 3 TPI) for re-sawing and cutting thicker materials. For general wood cutting duties in typical 3/4″ material, use a 4 TPI blade for coarse, fast cutting and a 14 TPI blade for slower, smoother cutting. A blade in the 6 to 8 TPI range provides good general-purpose performance.

How long does a sawmill bandsaw blade last?

On average your bandsaw blade should last 6 months to as long as a few years depending on what your cutting with it. Make sure to match your blade strength and quality to the project and material your cutting.

What kind of steel are sawmill blades?

Carbon steel is the most common metal used to manufacture sawmill blades and performs well for high production.

What is the best TPI for cutting wood?

If you’re looking to cut wood or other soft materials, you’ll need a blade with a TPI of 6 up to 20. For harder materials like metal, a TPI between 14 up to 36 is more suitable. The number of teeth can be found on the blade.

Why is my bandsaw burning the wood?

A majority of issues with wood burning is because of a dull saw blade. These blades may not be sharp enough to efficiently cut the wood, and thus create enough friction to heat and burn the wood. What is this? Dull blades make it more challenging to cut, which causes friction as you pass the wood through.

Is a wider bandsaw blade better?

The wider blades are stiffer overall (more metal) and tend to track better on the band wheels than narrow blades. When cutting thicker material, the wider blade has less ability to deviate because the back end, when in the cut, helps steer the front of the blade, especially if the side clearance is not excessive.

How many times can you sharpen a sawmill blade?

You should be able to sharpen your blade two or three times before needing to replace it, but sometimes breakage happens. Blade breakage can result from a range of situations. Common causes of blade breakage include: Dull teeth.

Are bandsaw blades worth sharpening?

Since a carbide-tipped bandsaw blade will cost well over $100, spending a third of the cost of the blade (or more) to get it sharp and working like new again can make financial sense. However the majority of bandsaw blades, the Wood Slicer included, are not worth spending money to have sharpened.

How thick of wood can a bandsaw cut?

Band saws are the undisputed champ when it comes to cutting curves and slicing through thick material. Many small band saws can slice though lumber a full four inches thick, and bigger saws handle six-inch cuts.

What’s the best way to cut hardwood?

The best saw blade for ripping hardwood is a rip blade. This blade is specially made for cutting through wood fibers, so it will cut through hardwood easily and leave a clean edge. Rip blades usually have 10 to 40 flat-topped (FT) teeth, which is a comparatively small number, but it will move through the grain quickly.

Can I use metal cutting blade to cut wood?

You can use a metal blade to cut wood. A circular saw blade cut metal in a sluggish rotational speed of 25m/s. They are driven by a motor having high power and an A/C vector drive. They are long lasting and non-reusable.

Do saw blades make good knives?

The biggest advantage of using an old saw is the lack of metallurgy you need to do. The blade is already the right hardness for holding an edge, so you don’t need to treat the steel to make it a good knife. However, blanks cut from the saw are sometimes a little too flexible, but you can work around (or with) it.

Are saw blades hardened steel?

Yes, circular saw blades are hardened steel. This is accomplished by positioning the blade near a source of intense heat. The often-utilized temperature is between 900 and 1,100 degrees Celsius, which is ideal for hardening steel blades.

Are old saw blades worth anything?

The reason is simple: old circular saw blades aren’t worth anything because they’re made with carbon steel. The only way to modify them is by adding some decorative elements but even then they will never become real jewelry pieces.