circular saw blade for metal canadian tire Related Question:

Can I put a metal cutting blade on my circular saw?

Only blades and discs specified for cutting metal should be used. These professional circular saw blades are perfect for cutting through aluminium, copper, lead and other non-ferrous metals; while these diamond cutting discs will make light work of cutting through stainless steel.

What is the best saw blade to cut metal?

Ferrous blades are ideal for cutting metals that contain iron, such as stainless steel or cast iron. Choose a non-ferrous blade when cutting softer metals, like aluminum or copper. For the best results, use a diamond blade that’s rated to cut the type of metal you are working with.

What TPI is best for cutting metal?

Cutting thinner metals, including sheet metal, requires a finer cut. Use 18-24 TPI bi-metal blades. For thicker metals such as steel pipe, angle irons, or tubing, use 14-18 TPI bi-metal blades. For aluminum, an 8-10 TPI blade is best.

Can a compact circular saw cut metal?

Compact Metal cutting circular saw that is powerful enough for cutting of rebar, conduit, sheet metal, tubing and plate.

Can carbide blade cut metal?

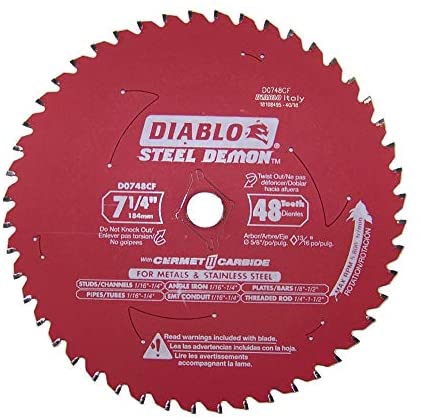

Tungsten carbide, called simple “carbide” in the building trades, is three times harder than steel; and when placed on circular saw blades, reciprocating saw blades and grinder discs, tungsten carbide cuts cleanly through steel.

What is the best tool for cutting metal?

Hacksaw. The original metal-cutting tool, the manual hacksaw, is an easy, inexpensive option for cutting through metal (and a slew of other materials). Ideal for small projects and home improvement needs, the hacksaw is typically one of the first tools a homeowner purchases, thanks to its low cost and versatility.

What type of blade can cut through steel?

Carbide tipped blades cut harder, denser metals like hardened steel, cast iron, alloys including boron steel, and higher grades of stainless steel. These blades are extremely hard, heat-resistant, and impact-resistant.

How do you cut sheet metal with a circular saw?

Clamp the Metal to Workbench: A metal section to be cut must be hung over the edge of the blade. This helps in the uniform cutting of the metal piece. By turning the circular saw, the blade starts cutting the metal at its desired speed.

Can I put a metal cutting blade on my miter saw?

Although mitre saws were traditionally used for cutting wood, with the correct blade they can make light work of cutting through steel and aluminium profiles at an angle.

What is 18 TPI for cutting?

Blades 12-18 TPI are typically used for metal and denser materials as well as finish cuts in wood. The 18-24 TPI range is almost always used for metal cutting. Pro Tip: Always keep 3 teeth in contact with the material being cut.

What does 18 TPI mean?

TPI explained TPI is the number of teeth the blade has per inch. If you’re looking to cut wood or other soft materials, you’ll need a blade with a TPI of 6 up to 20. For harder materials like metal, a TPI between 14 up to 36 is more suitable.

Is more TPI better?

Woodworkers quickly learn that the number of teeth-per-inch (TPI) on the blade has a big impact on the quality of a cut. The general rule of thumb is “the more TPI, the smoother the cut.” The true answer, however, is just a little more complicated than that, as you’ll learn once you understand how saw teeth work.

Can carbide tipped blade cut aluminum?

Cutting aluminum with a circular saw requires a few special steps. Ensure that you have the right blade. A carbide blade works but is more likely to grab the material. If possible, purchase a blade specially designed for cutting aluminum and other non-ferrous materials.

Can I use a circular saw to cut aluminum?

A blade you use for woodworking will work on an aluminum application. However, you will need to ensure that the blade has carbide tips, and it is necessary to be more cautious with metal. That is because the tips can get ahold of the material, which will destroy the cutting piece or the blade.

What is a demolition blade?

Demolition Blades are best for nail-embedded wood. They are thicker for heavier duty applications and range from 6 to 11 TPI. You will often see demo blades with variable TPI to better cut the range of materials encountered in a demolition job.