After cutting about 20 feet the saw took more effort to cut the ridges, threw more sparks and metal chips and shavings were left behind. The blade is clealy dulling I am now 40% through and have cut approximately 60 liner feet of the 24 gauge panels. Great Blade Great blade for metal jobs – would use one again and recommend it to anyone – especially to metal roofing contractors.

“One LENOX blade easily lasts as long as 20 of the blades we used before. They cut like butter. You hardly have to put any pressure on the LENOX blades, and they cut in at least half the time.” WARRANTY. LENOX warrants to the original owner that its products are free from defects in material and workmanship for the following periods from the date of the original purchase: Hand Tools are warranted for the anticipated life of the tool; torches and torch accessories are warranted for three years. This warranty is void if the product is repaired or modified in any way by anyone other than LENOX. LENOX makes no other warranties, express or implied, concerning the product or the merchantability or fitness thereof for any purpose.

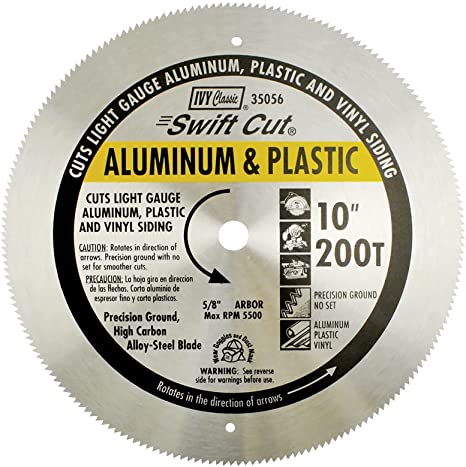

circular saw blade for metal siding Related Question:

Can a circular saw blade cut metal?

It may not be an obvious choice, but fitted with the right blade, a circular saw is a great metal-cutting tool. In our test, it cut through rebar like a hot knife through butter. You can cut mild steel up to about 3/8 in. thick using a ferrous-metal-cutting blade.

What blade is best for cutting metal?

Ferrous blades are ideal for cutting metals that contain iron, such as stainless steel or cast iron. Choose a non-ferrous blade when cutting softer metals, like aluminum or copper. For the best results, use a diamond blade that’s rated to cut the type of metal you are working with.

What tool do you use to cut metal siding?

Tin snips are the most affordable tool for cutting metal panels, and they are extremely easy to find.

Can you turn a circular saw blade backwards to cut metal?

You can run a saw blade backwards and it cuts pretty well. However it is not at all a good idea. The two big reasons not to do this is that saw tips are much more likely to come off if the saw blade is run backwards and that the whole saw blade is much more likely to come apart if it is run backwards.

What is the best tool for cutting metal?

Hacksaw. The original metal-cutting tool, the manual hacksaw, is an easy, inexpensive option for cutting through metal (and a slew of other materials). Ideal for small projects and home improvement needs, the hacksaw is typically one of the first tools a homeowner purchases, thanks to its low cost and versatility.

Can carbide blade cut metal?

Tungsten carbide, called simple “carbide” in the building trades, is three times harder than steel; and when placed on circular saw blades, reciprocating saw blades and grinder discs, tungsten carbide cuts cleanly through steel.

What type of blade can cut through steel?

Carbide tipped blades cut harder, denser metals like hardened steel, cast iron, alloys including boron steel, and higher grades of stainless steel. These blades are extremely hard, heat-resistant, and impact-resistant.

What is the best TPI for cutting metal?

Cutting thinner metals, including sheet metal, requires a finer cut. Use 18-24 TPI bi-metal blades. For thicker metals such as steel pipe, angle irons, or tubing, use 14-18 TPI bi-metal blades. For aluminum, an 8-10 TPI blade is best.

How do you cut sheet metal with a circular saw?

Clamp the Metal to Workbench: A metal section to be cut must be hung over the edge of the blade. This helps in the uniform cutting of the metal piece. By turning the circular saw, the blade starts cutting the metal at its desired speed.

Can I cut metal roofing with a circular saw?

It’s very easy to cut yourself on the metal roofing, if you don’t have some protective gloves on. You don’t want to use the high speed of a skill saw, or any type of circular saw, because it will create too much heat.

Can you cut corrugated metal with a table saw?

You can use a sawing table or a set of sawhorses. Place your corrugated metal on top of your work surface so that there isn’t anything blocking your saw blade directly underneath your cutting line. Switch out your saw blade for any blade designed for metal. Unlock your blade guard and replace the blade if necessary.

How do you cut sheet metal straight at home?

For thin sheets of metal, you can use tin snips to cut through it. To make detailed cuts in sheet metal, use a Dremel blade. Clamp the sheet metal to a work table and press the Dremel blade against it. Move the blade along the intended line until you reach the end of your cut.

What happens if you put a circular saw blade on backwards?

The speed of the blade combined with the backward teeth make a nice, clean cut with very little operator effort, and without the teeth tearing out and distorting the metal.

Which way should the teeth face on a circular saw?

The teeth should be cutting UPWARDS, in a clock-wise direction. You’ll also notice that when your blade is installed correctly, the teeth will be pointing upward. Remember: circular saws (as most saws) cut on the upward stroke.

How do I know if my circular saw blade is backwards?

Correct Circular Saw Blade Direction However, saw and blade manufacturers make it a little easier for you. When you look at the saw’s blade cover there’s an arrow to let you know which direction the motor turns. On the blade, there’s usually a directional arrow as well.