Circular saw blades are renowned for their endurance and strength, so people frequently inquire about the hardening of circular saw blades. The steel blades are heated to between 860- and 1100-degrees Celsius, based on the type of steel used to create the circular blade. Circular saw blades are made from high carbon steel so technically yes circular saw blades are made from spring steel.

Metal cutting saw blades can usually be found in two forms. If you find a very old American made circular saw blade, it may be made out of L6 steel. Cut Metal with Your Circular Saw It may not be an obvious choice, but fitted with the right blade, a circular saw is a great metal-cutting tool.

Choosing the right blade for your circular saw is crucial if you want your circular saw to operate at peak efficiency. I will tell you about the different kinds of circular saw blades and what kind of blade is best for each job. Inexpensive: The circular saw blades are cheap compared to table saw blades.

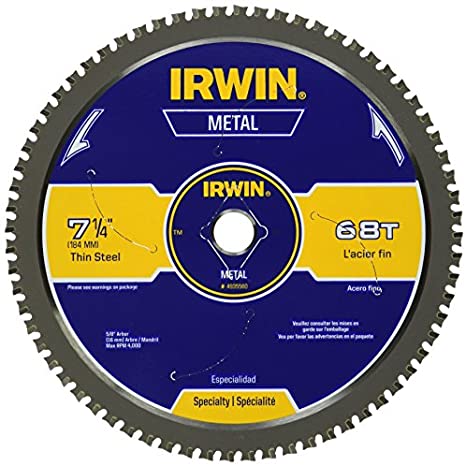

Not only will you need a different blade for cutting metal than you would for cutting wood, but a metal-cutting blade should not be used in the same saw as the type used for wood. If you do decide to use a wood saw on metal, only use a 7 1/4-inch blade and preferably a worm drive blade, which provides extra torque. As always when purchasing a blade for your circular saw, make sure it has the right diameter and arbor size to match your saw.

Manufacturers of circular saw blades use a core hard metal, and then add alloy compounds such as chrome, vanadium, or carbides to ensure the saw blades are wear-resistant, corrosion-resistant, and have a long service life. Steel Types That Circular Saw Blades Are Made Of. There is a variety of steel grades that different manufacturers use to make circular saw blades. From handheld blades and chop saw blades to circular saws blades, the material used in the core may be the same, but the teeth are reinforced with alloys to increase quality and hardness.

circular saw blade metal type Related Question:

What type of metal are circular saw blades made of?

Spring steel is commonly referred to as the steel springs are made out of which can consist of different types of steel such as medium carbon steel, low-alloy manganese, or high carbon steel. Circular saw blades are made from high carbon steel so technically yes circular saw blades are made from spring steel.

Are circular saw blades hardened steel?

This is the entire process of hardening blades, and most circular saw blades have at least hardened teeth. High-quality circular blade are made completely hardened and that’s what you should looking for. You might also find bi-metal blades that have a tough body with an outer rim of hardened steel.

Can I put a metal blade on my circular saw?

Only blades and discs specified for cutting metal should be used. These professional circular saw blades are perfect for cutting through aluminium, copper, lead and other non-ferrous metals; while these diamond cutting discs will make light work of cutting through stainless steel.

What is a saw blade made of?

The whole saw blade is made of High-Speed Steel (HSS). HSS saw blades are mainly used to cut steel, copper, aluminum and other metal materials. If high-strength steels (e.g., stainless steel) are to be cut, the blades made of cobalt HSS (e.g. M35, M42) should be used.

What is L6 steel?

L6 Tool Steel is a versatile, oil-hardening tool steel that is characterized by very good toughness. L6 tool steel is suitable for use as tools, dies, and machine parts, which require a good combination of hardness and toughness.

How good is 1075 carbon steel?

1075 steel is a softer, more pliable grade than 1095, often used to manufacture band knives or blades that require forming. 1095 steel is typically harder than 1075 offering better edge retention than 1075. Recommended for thin gage, disposable blades. Available in Polished or Bright Blue finishes.

Do old saw blades make good knives?

The biggest advantage of using an old saw is the lack of metallurgy you need to do. The blade is already the right hardness for holding an edge, so you don’t need to treat the steel to make it a good knife. However, blanks cut from the saw are sometimes a little too flexible, but you can work around (or with) it.

Does 4140 make a good knife?

Original Becker Knife and Tool Machax’s (pre blackjack) were 4140. They were really tough and never broke. They really weren’t awesome edge holders IIRC.

What is 15N20 steel?

15N20 is a high nickel alloy most commonly used with 1084 or 1095 to create pattern welded or “Damascus” steel. We carry a variety of different thicknesses up to 1/8″ and have found that even 15N20 on its own makes great knife steel. In other industries, it is used for saw blades.

What kind of saw will cut metal?

Circular Saw with Metal Cutting Blade or Metal Circular Saw Roofing, sheet metal, and corrugated metal—basically any metal that generally requires just a simple, straight cut—can be cut by a circular saw with the right blade.

Can carbide blade cut metal?

Tungsten carbide, called simple “carbide” in the building trades, is three times harder than steel; and when placed on circular saw blades, reciprocating saw blades and grinder discs, tungsten carbide cuts cleanly through steel.

Can you turn a circular saw blade backwards to cut metal?

You can run a saw blade backwards and it cuts pretty well. However it is not at all a good idea. The two big reasons not to do this is that saw tips are much more likely to come off if the saw blade is run backwards and that the whole saw blade is much more likely to come apart if it is run backwards.

How do you select a saw blade for different materials?

Typically, thicker metals, plastics or wood sections require saws with bigger blades, while hard materials require saws with larger teeth. The actual number of teeth on the work is crucial, with at least three on each section of material being worked.

What steel is used for hand saw?

The high-carbon steel is top for making great knives that take and keep a good edge. The high-carbon steel in hand saws that are over 25-30 years old is also of excellent quality and will make an exceptionally strong knife that takes and holds a fine edge for a long time.

What is O1 steel?

O1 Tool Steel is the original oil-hardening, “non-shrinking” tool steel that can be hardened to the Rockwell C 65 range from a low austenitizing temperature. O1 is a general-purpose tool steel that is typically used in applications where alloy steels cannot provide sufficient hardness, strength, and wear resistance.