If the base plate is not parallel to the blade, the saw will also want to travel to the side. If your saw was dropped at some point the base plate could easily be out of alignment. Turning to the right would indicate that the base is farther from the blade at the front than it is at the back.

05-24-2020, 12:15 PM #1 Circular Saw insists on turning to the right With or without a jig, with a jig that extends far enough out at the beginning to ensure base plate is flush against it the “Jig” for the entire cut, watching the line… it absolutely insists on turning to the right. If the base plate is not parallel to the blade, the saw will also want to travel to the side. Turning to the right would indicate that the base is farther from the blade at the front than it is at the back.

It is much easier to move the saw across the board than to manhandle the sheets through a contractor saw. Here is a trick… set up 4 sawhorses in a row, lay a sheet of plywood on them, lay a sheet to 1″ styrofoam on that, lay the sheet of plywood to cut on the styrofoam, clamp on the plywood fence jig, set the saw blade to cut through the plywood and about 1/8″-1/4″ into the styrofoam, make the cut. There will be no tear out and the plywood will not fall to the floor.

Measured with a digital caliper, the left edge of the baseplate is 5.116 inches from the saw blade at the rear of the blade and 5.040 inches at the front. “If you make an external base to attach to the bottom of your existing base, you can also make it with a zero clearance slot at the front of the blade to minimize chipping. Just make sure that the clearance hole for the rest of the blade is large enough for the blade guard to operate properly. I made one for my saw out of 1/8” clear lexan, attaching it to the saw base with double sided carpet tape, and I can now make chip free cuts when I’m breaking down sheets of cabinet plywood. Of course like any new saw the default blade it comes with is crap.

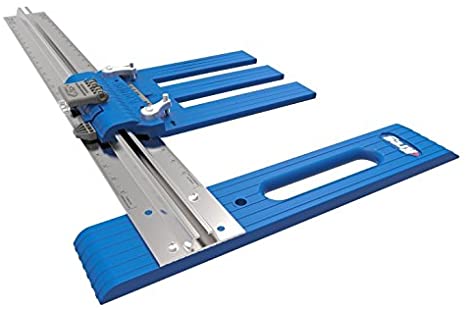

“The fence on my PC circular saw is about 1/16” out of parallel. The basic idea is a straightedge with a base that aligns with the saw blade, but the slick part is that the straightedge has a slot in it that mates with a ‘sled’ that holds your circular saw. What I mean is that the edge of the sole plate on which the saw slides across the wood is not parallel to the blade.

Now, belatedly, I checked that too, and find the base of the CS is itself not exactly parallel to the blade – though it is not as bad as the CSBP. Have to tell you that I had to drill holes in the metal CS base to fix the CSBP – a pain in itself. B ) detach the CSBP from the CS’ base and re-attach, this time keeping it parallel to the blade and ignoring any non-parallel from the CS base. C ) try and re-attach the CS base itself to make it parallel.

circular saw blade not parallel to base Related Question:

Why is my circular saw cutting crooked?

The nuts and screws that hold the blade of a circular saw can become loose when the saw is used for a long time. The blade may also become misaligned. Tip: If the blade is wobbling because of loose nuts and screws or improper alignment, you should fix it appropriately. A properly fixed blade will not wobble as you cut.

Can a circular saw be adjusted?

A circular saw has a depth adjustment lever or knob that releases or loosens to allow for adjustment of the saw’s bottom plate, often called the “shoe.” First unplug your saw, then disengage this lever so that you can freely adjust the cutting depth by raising or lowering the bottom plate.

Why does my circular saw blade stop spinning?

The most common reason your circular saw blade stops spinning is because your workpiece is pinching the blade. This can also cause the blade to kickback. To prevent this from happening you need to support your workpiece properly to allow it to set securely through the entire cut.

Why is my circular saw pulling to the right?

If the base plate is not parallel to the blade, the saw will also want to travel to the side. If your saw was dropped at some point the base plate could easily be out of alignment. Turning to the right would indicate that the base is farther from the blade at the front than it is at the back.

How do you test a circular saw blade?

Make sure the saw blade is set at exactly 90° to the shoe and cut into a piece of wood a few inches. Guide the saw against a square or straightedge. Stop the blade and back the saw out of the cut while keeping it against the edge guide. See if the kerf made by the blade lines up with the marker.

Why is my Mitre saw not cutting straight?

The primary reason why a miter saw might not cut straight is an inability to clamp the material down. The machine is designed to pull the material towards the blade during each cut, and if there’s a malfunction in this process, it might result in inaccurate cuts.

What is the closest you should put your fingers to the blade while it is running?

Do not put your fingers closer than two inches from the blade. 3. Do not place your hands directly in line with the blade while cutting stock. 4.

How do you keep a circular saw guard up?

This can be accomplished by rotating the guard into the saw, and holding onto the black handle with the thumb of the right hand (the trigger hand is the left). Pull the guard back before pulling the trigger.

How far down do you set the circular saw cut depth?

Don’t clamp both sides of a cut. For efficiency and safety, set the blade depth no more than 1/4-inch below the thickness of the board.

How do you cut straight with a circular saw without a guide?

To ensure a straight cut, press the saw firmly against the straightedge as you push it along. Clamp a perfectly straight board or metal straightedge to a sheet of plywood to make cabinet-quality straight cuts.

When should a portable circular saw operator unplug the saw?

12. The saw must be unplugged from the power source when changing the blade, adjusting the depth of cut, or doing any adjustments in the cutting operation. 13. Every student must obtain permission from the instructor prior to using the portable circular saw.

What is the bevel adjustment on a circular saw?

Circular saws commonly include an adjustment that allows you to set the blade angle anywhere from zero to 45 degrees. Using this feature, you can cut a bevel along the length of a board and a miter across the end.

What is it called when cutting with the grain of the wood?

Definitions. Rip cut comes from rip: to split or saw timber in the direction of the grain, and cut: to divide with a sharp-edged instrument.

How shallow can a circular saw cut?

Circular saws turn corners about as well as a freight train, and standard models will cut only about 2 1/2 inches deep. There are ways around the shallow cut—for example, you can flip over a 4×4 and cut from two sides—but the curve limitation has no work-arounds.

Why is my saw getting stuck?

The wood you are sawing is closing the kerf and pinching the blade, Your cut isn’t straight, The set of the saw teeth is not large enough, so the kerf created by the blade isn’t wide enough to allow the saw room to pass without undue friction, or. Your saw teeth are too fine for the wood you’re sawing.