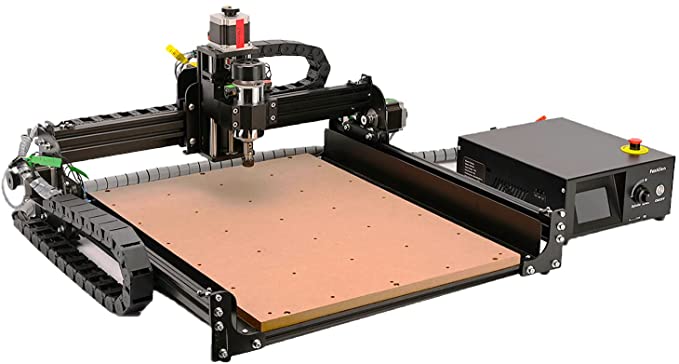

The 4040-XE CNC Router has a 300W spindle and stepper motors that are more powerful and efficient. Max speed is 2000mm/min and the spindle speed ranges from 0 to 100,000.

The control board, power supply, emergency stop, and wires are all put together in a new design box that is simple to use, easy to clean, and safe. The controller has a 3.5″ touchscreen LCD that can also be used as a controller when the game isn’t running. There is 110V at the input.

Many different materials can be engraved, cut, and drilled with this machine. It can work with wood, metal and other types of materials like MDF and acrylic. Home and business will love it.

There is a lot of space that can be engraved, with a size of 15.75″x15.75″x2.56″ (400x400x65mm). It can handle both small and big things. The CNC machine is based on GRBL, which means it can be used with GRBL-control software to run it.

Easy to put together. The main parts are already put together, so it only takes 15-30 minutes to put the whole thing together. Labels on wires make it easier to connect them and make it easier to keep track of them.

Having just spent $1000 on this thing, I wanted to love it, but I can’t be sure it’s safe. First, I’m not a mechanical novice. I won’t brag about how many things I’ve built, but I thought it would be important to at least say that I’ve done this before. Assembling was a piece of cake. Kudos to them for how everything is packaged, with labels on each piece, and so on. This makes it clear where everything should go. They were very easy to understand and very visual. None of that bothers me. The Z-probe works well and is built well. But the devil is in the small things.

If you haven’t used the machine for a few days, there are a lot of big problems.

In this case, the stop switches on the Z axis don’t work because they don’t touch the bracket that should. See the picture. This looks like a design flaw, and it wasn’t something that was done at home. In other words, it came from the factory that way.

In this case, this is not an issue anymore. The screws that hold the Y1 spindle in place were a little too loose. Keep an eye on your motor collar set screws. The lesson was learned.

A few times after running it back and forth, this hasn’t happened again, so we’re going to say 3. ——. Track for the Y axis had a few places where it slowed down a little. Toward the back of the table, there were a few spots that seemed to stick, which made the table move a little. I moved the Y axis forward and back across the whole table a lot, and this seems to be getting better.

No, I wouldn’t. Before you start working with bigger pieces of stock or more expensive materials, make sure you run some tests to make sure everything is working right. Check everything at least three times, even the screws that came from the factory already put together.