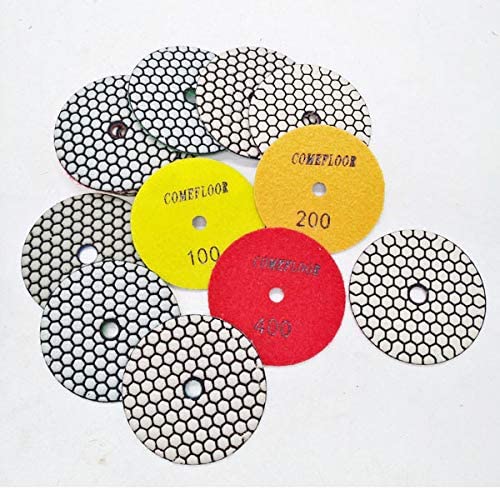

SIZE AND GRIT: The diamond polishing pad measures 4 inches (100mm) in diameter. Diamond polishing pads are available in a variety of grits, including 50#, 100#, 200#, 400#, 800#, 1500#, and 3000#.

GOOD FOR POLISHING STONE: Do an excellent job of polishing the stone by dry means, taking care not to mark or burn the stone’s surface.

VELCRO BACKED TO PREVENT SEPARATION: This product can last for a long time, and the Velcro backing helps to keep it from coming loose from the machine.

HIGH EFFICIENCY AND GLOSS: Excellent for polishing marble, granite, tile, and other hard-to-polish stones with a high sheen. High efficiency and high gloss finishes are achieved in a short period of time.

INSTANT CONNECT AND REMOVE: The velcro backing on the polishing pad makes connecting and removing it from the machine very simple.

Doing your own housework is simple and straightforward.

Size:4.

Description of the Produc.

Coming Soon! ComeFloor Diamond Premium Resin Matte Dry Polishing Pads are made from resin with a high diamond concentration inside, never using Sic as an additive, with aggressive and tenacious properties, superior thermal conductivity, and can only be used by drying metho.

They are designed for a variety of applications, including marble, granite, concrete, terrazzo, porcelain, and engineered stone, among other materials.

Information on the Dimension.

Diameter(Size):4Inch(100mm.

Thickness:3m.

Grit:50#,100#,200#,400#,800#,1500#,3000.

Dry/Wet:Dr.

Characteristics and Advantage.

Long lifespan/Never marks or burns the stone/Never marks or burns the stone.

Light that is bright, clear, and never fades.

High gloss finishes in a short period of time.

Improvements in heat transmittibility performanc.

Machine that has been use.

Another type of hand machine, such as an angle grinde.

Contents of the Packag.

A set of seven pieces.

Each set comes in its own carton box.

How to make use o.

Always remember to wear eye, nose, mouth, and hand protection when working with chemicals.

Never use a high-speed grinder at a speed greater than the rated RPM.

If the stone surface is severely damaged, you can start with grit 50 and work your way up to 3000. Before moving on to the next grit, make sure the entire polished stone surface has the same level of smoothness before moving on to the next grit.

If this is the case, continue polishing with the same grit.

Don’t forget to include any grit in between.

Starting at grit 800, the majority of the stone will be shiny.

It is recommended that the work surface be thoroughly cleaned before use.

Otherwise, it will have an adverse effect on the grinding effect.

What is ComeFloor.

ComeFloor has been in business for ten years.

We manufacture a wide range of diamond saw blades, flexible polishing pads, diamond grinding wheels, abrasive brushes, and other abrasive products, among other things.

Our tools are widely used by stonemasons, marble and granite fitters, concrete cutters, and bricklayers, among other professions.

At the moment, our products are primarily exported to the United States, Canada, Germany, Russia, Brazil, Australia, and other countries.

We strive to provide our customers with the highest quality products at the most competitive prices.

If you are looking at this page, it is likely that you have attempted to achieve the 3000 grit fine, shiny countertop finish. To achieve the desired appearance, one must progress through the grits in a progressive manner. As a general rule, an 800 grit finish has a leather-like appearance. The number 1500 produces a fine matte finish.

There is no quick way to achieve the finer finish that you desire. These diamond grit embedded discs attached to an angle grinder are, quite frankly, the only way to get there short of the ancient Egyptian approach involving many hands and weeks/months of labor and time. You can learn the technique by watching videos on YouTube.

This is about my fourth or fifth set. They have a long shelf life. It is absolutely necessary to polish under flood/flowing water in order to keep the polishing compound lubricated.

Excellent value for money.