The last seen feature, which provides the street address of where your compact drill/driver was last in range of your tool connect-enabled device, helps you save time and money by reducing time and money wasted.

Comparing DEWALT Brushless motors to 18V NiCad brushed motors, the latter provides up to 75% more runtime.

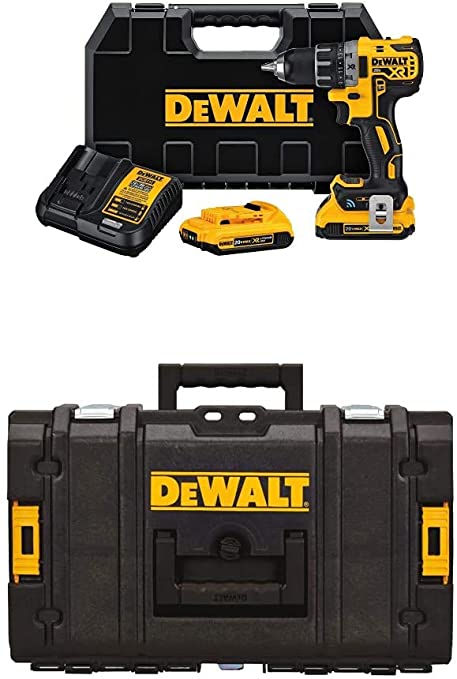

A structural foam box for a strong and long-lasting structure.

Removabl. 2 different-sized cups for small parts organization, as well as drill and bit organizers in the inner lid.

What to do if your drill bit keeps falling out.

A drill bit was loaded into my new Dewalt drill, the chuck was tightened and the trigger was briefly depressed.. and the bit fell out of the hat. I went through this process a couple of times more and got the same result each time.

I was extremely dissatisfied when my brand new drill proved to be unusable. I was debating whether or not to return the drill to Amazon.

Then I remembered reading a blog post that described a method for tightening the drill bit. I couldn’t make sense of the description, but there was still hope.

After experimenting with a few different approaches, I’ve discovered that there is a way to tighten the bit while still ensuring that it remains in place.

Step 1: Insert the bit into the chuck and rotate the chuck counter-clockwise to tighten the bit. Turn the chuck until you hear a loud “click” at the end of the turn. Continue your efforts. Continue to turn the chuck counter-clockwise after you hear the click sound again. You’ll hear some softer clicking sounds during this process. When the bit is snug in the chuck, come to a halt. “(Getting past the initial loud “click” sound is essential to getting this to function properly). It is possible that the bit will not tighten in the chuck if you stop turning right after hearing the first loud “click..

Step 2: Rotate the chuck counterclockwise until you hear (or feel) a softer “click” sound (or both). This will have the effect of something falling into place. Turn the chuck only about an eighth of a turn until you hear the softer clicking sound that indicates the chuck is ready. (This is the second key to ensuring that the bit remains in the drill..

Step 3: Rotate the chuck counterclockwise once more until you hear a loud “click. Once you hear this clicking sound, you should stop turning. It is not necessary to tighten the chuck after you have heard the sound. (This is the third and final step in ensuring that the drill bit remains in the drill..

Step 4: Pull the trigger on the drill to ensure that the bit is securely fastened in position. The majority of the time, the bit will be firmly secured in the chuck and you will be ready to use your drill right away.

Note: On rare occasions, even after following all of the above steps, the drill bit will remain loose. I’m baffled as to why this is happening. Continue to follow the steps outlined above, and the bit will remain in place.

This is the most bizarre method of installing a bit in a drill that I have ever tried, but it does the job.

I’m finally able to use my brand new Dewalt drill!. I’m hoping that this information is useful to someone else.