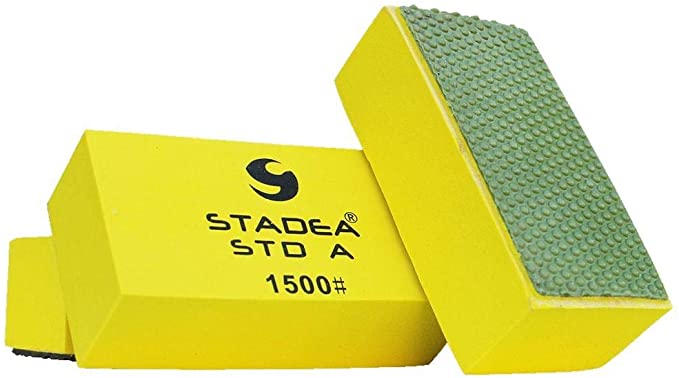

One (1) piece grit 1500 diamond hand polishing pad – STADEA (Series STD A) professional grade pad for glass, marble, concrete, and stone polishing.

Polishing pads with a 1.2 MM thickness and a semi-flexible foam holder, overall dimensions: 4-3/8″ (L) x 2-1/8″ (W) x 1-1/2″ (H.

Made from high-quality diamond powder, this diamond tool is sharp, aggressive, and long-lasting.

Excellent for scratch removal, acid etch stains repair restoration, spot removal manual stone polishing, and other stone care applications.

It is excellent for polishing marble, glass, concrete, granite, terrazzo, travertine, artificial stone, granite marble tile, and natural stone polishing, amongst other materials.

Size.

Pos8 Grit 1500 is a grit that is used in the construction industry.

Polishing, grinding, and restoring/cleaning areas that are difficult to reach with other polishing tools such as wet grinder polishers, angle grinders, and so on are all possible with diamond hand polishing pads. In addition to polishing corners, contoured surfaces such as sinks, and the join of two bullnose surfaces, this tool is also useful for granite polishing, concrete polishing, marble polishing, terrazzo polishing, travertine polishing, glass polishing, and their restoration, among other things. Floor polishing, counter top polishing, stone sculpture polishing, and other applications are possible with these diamond tools. For a small polishing project, it could be very useful and cost-effective. Hand polishing can be more time consuming than polishing with tools such as grinders and other similar devices. Diamond hand polishing pad for Grit 1500 from STADEA STANDARD A (STD A) includes 1 polishing pad for Grit 1500.

Instructions on how to polish marble concrete glass stone by hand are as follows.

1) Put on your glasses, gloves, and apron.

2) Firmly anchor the stone in place.

3) Apply a thin layer of water to the surface and begin polishing with grit 50 in a clockwise direction. Squeeze the water and look at the surface at a 30-45-degree angle for 30 to 45 seconds. Before moving on to the next grit, make sure that the entire polished surface has the same level of smoothness. If this is the case, continue polishing with the same grit. Surfaces with grits greater than 400 are generally scratch-free.

4) Repeat step 3 for each higher grit one by one, starting with grit 50 and working your way up to grit 3000. Don’t forget about the grit in between. Starting at grit 800, the majority of the stone will be shiny. If there are still scratches visible after using grits 800 and 1500, this indicates that step 3 was not followed correctly in the lower grits.

STADEA’s Background Informatio.

STADEA provides industrial diamond tools, power tools, as well as a diverse range of tool accessories to its customers. In many natural stone fabrication shops and artificial stone manufacturing shops all over the world, STADEA wet dry polishing pads (also known as diamond hand polishing pads), diamond hole saw core drill bits (also known as diamond hole saw core drill bits), cup wheels (also known as diamond profile wheels), router bits (also known as tuck point blades), diamond saw blades (also known as diamond saw blades), etc. are used.

STADEA is a registered trademark of ePortal LLC, which is based in Santa Clara California.

I purchased the 200, 800, 1500, and 3000 to finish the edges of some marble tile that I had purchased previously. Because I was working with soft stone, I skipped the 400 and 50 grit sandpapers.. However, given the price of each pad, it simply would not have been cost-effective for me to purchase all of them in order to expedite the process and save myself some time in the future.

Using the four pads I purchased, I was able to polish approximately 14 linear feet in approximately 3 hours. The final finish was almost as good as machine quality, but it took a lot of elbow grease to get there. I wouldn’t recommend using these for anything more than minor touch-ups and small jobs, however.

I would also advise caution when working in close proximity to completed stone. Using the 200 grit pad, I attempted to polish the edge of a tile that had already been installed and managed to score a neighboring tile in the process. It caused enough damage that I had to repolish the existing tile to the same degree that the unfinished edge had been polished previously. This could have been avoided entirely if the bordering tile had been taped down with masking tape in the proper places.

Bottom line: The pads perform as expected, but given the high cost of each pad, I would strongly advise using a machine-based polishing system if your intended job is more involved than a minor fix.