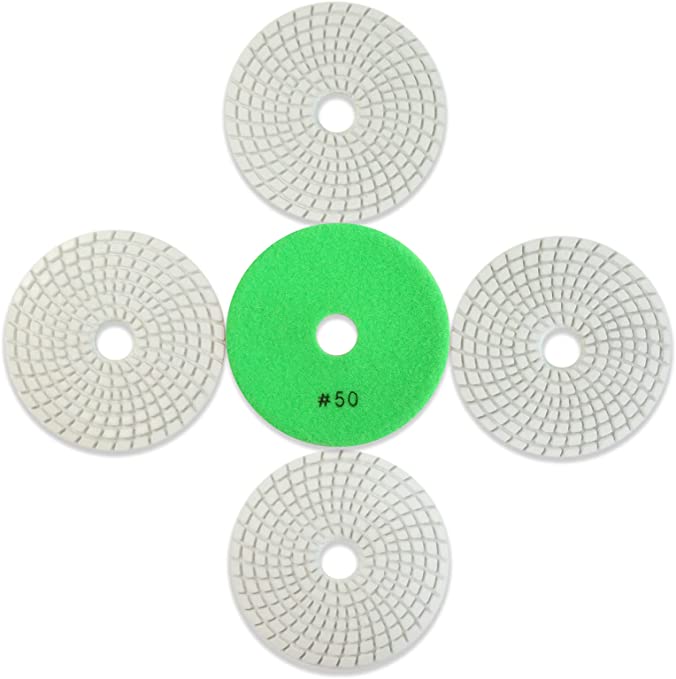

‘Applicable Materials’ are those that can be used. 5 pieces of 4 inch diamond polishing pads, 50 grit, are ideal for profiling, restoration, and renovation of granite, marble, quartzite, concrete, cement floor, terrazzo, tile, and artificial stone, to name a few applications.

A long nylon backing, which is strong and firmly adhered, is used to create the Terrazzo polishing pad 50 grit, which is resistant to tearing and is therefore less likely to be damaged by repeated tearing.

Granite Polishing Pads with Exceptional Performanc. Diamond micro powder and a special resin bonding agent are used to create this 4 inch granite diamond polishing pad with 50 grit. With high grinding power, high polishing efficiency, good flexibility, and a long service life, this machine is an excellent choice.

When it comes to wet or dry polishing, quartz stone polishing pads can be used for both wet and dry polishing. For the best results, we recommend using a wet polishing pad to reduce dust generation during the polishing process and to improve the gloss in a short period of time.

The best RPM is 2200. Designed for use with a professional polishing tool, this cement polishing pad 50 grit is color coded according to grit size for easy identification. It has an optimal RPM of 2200 and a maximum RPM of 6000, making it a versatile accessory. operates between 2500-5000 RPM in order to avoid causing damage to the surface of the ston.

The Polishing Effect Produced by timeriver Diamond Polishing Pads Is Similar to That of a Mirror.

1. Polishing without the use of a dead angle.

It is possible to properly bend a quartz stone polishing pad, and a curved table surface can be used in the shaped table surface, which makes the work much easier.

2. The design of the seam.

The design of the concrete polishing pad incorporates a slit, which makes the pad softer, has higher wear resistance, has a longer service life, has rapid heat dissipation, does not cause color loss, and does not result in a burned abrasive pad.

Timeriver Stone Polishing Tablets are the name of the product.

5 pieces per box; total of 5 pieces.

Diameter of the inner ring: 0.79 inches/2 c.

4 inches/10 centimeters in diamete.

Diamond micro powder is used as a material.

Mesh weight: 50.

Specifications: excellent durability, strong grinding power, and resistance to staining; good softness; high clarity; and good gloss.

Process of grinding.

30# to 150# for rough grindin.

Polishing the flatness of the grinding material and grinding the shaping surface into place are two tasks that are performed by abrasive discs.

200# to 400# for semi-fine grindin.

Even though the rough grinding marks will be removed, a new finer grain will be formed, and the processing surface will be polished to a more flat surface.

500# to 2000# for fine grindin.

After fine grinding, the pattern, grain, and color of the product will be clearly visible, and the surface will be fine, smooth, and slightly glossy, resulting in a product with a distinct appearance.

3000# to 10000# for fine grindin.

After processing, the product leaves no trace visible to the naked eye, the surface becomes increasingly smooth, and the gloss reaches approximately 90 degrees.

Caution.

The sticky discs must be used in conjunction with the water abrasive discs when operating them. Make certain that the discs are tightly adhered to the machine when operating them.

2. When polishing, you must add water to keep the polish from becoming too hot.

3. Polished tiles with a mirror finish are not suitable for processing.

4. When working, it is necessary to wear protective equipment such as labor gloves.