DIY CNC 3018PRO-M firmware updat. In order to ensure that you can safely monitor the engraving process, the Mini CNC Machine is equipped with two 5mm acrylic baffles on either side of the machine. This is an excellent tool for CNC entry. Easily curved text on a variety of everyday materials. Excellent for those who are interested in CNC, as it allows you to engrave the model quickly and efficiently.

CNC Engraving with a Large Work Surface Are. The 3018pro-M has an effective engraving area of 30 x 18 x 4.5 cm (11.8 x 7.1 x 1.8″), which is large enough to accommodate the majority of projects. GRBL is the control software used. Motor for the spindle: 775 spindle (12-36V. 24V:10000 revolutions per minut. System requirements: Windows XP, Windows 7, Windows 8, Windows 10, and Linux.

Using a ‘Offline Controller,’ you will not be required to connect your computer. Manually adjust the location of the X, Y, and Z axes as the engraving starting point, manually open and close the spindle, manually open and close the cooling fan. Notification: Please avoid using your computer and the Offline Controller at the same time, as this will cause the communication to be disrupted.

Control Board: Integrated Driver Chip + Fixed Heat Sink + External Fan + Sturdy Casing to help extend the life of the control board, Self-contained short circuit protection, and is difficult to break or modify.

A wide range of materials can be carved including wood, plastic, acrylic, PCB CCL, soft metals like copper and aluminum, and other similar materials; however, hard metals, jade, and other hard materials are not suitable for carving. However, if you get stuck, please contact us with any questions that may arise. Assembly instructions are included. Download the English manual and software from the links below.

CNC 3018Pro+M Kit is an abbreviation for CNC 3018Pro+M.

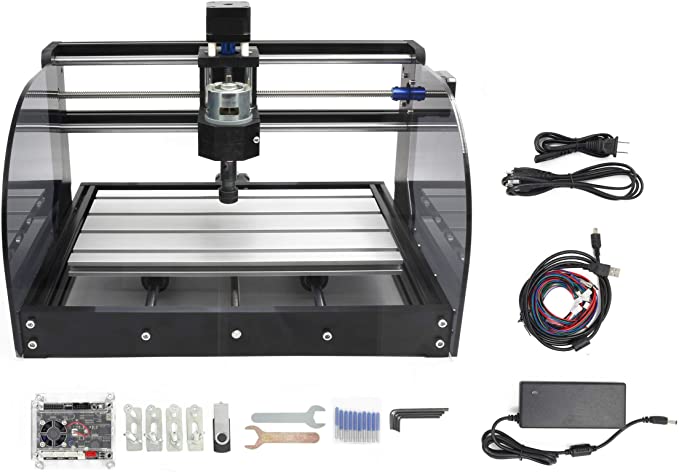

Included in the package are.

A complete 3-axis CNC machine kit (GRBL 3018 Pro Max) is included in the price ( Self-assembly,without laser .

There is one board for the GRBL controller.

1. 1 x Spindle motor with an ER11 collet on the end.

1 x U-Disk (Universal Serial Bus.

10 x Drill bits with a flat botto.

4 x Dinner Plate.

1 terabyte (U) dis.

Allen wrenches in a se.

755 Spindle motor (included).

Specification.

CNC 3018 Pro Max 3-axis laser engraving machine is the name of the item.

30x18x4.5 cm is the size of the working area (Approx.11.81×7.08×1.77 inches.

Mesa dimensions: 30x18CM (approximately 11.81×7.08 inches.

Dimensions of the frame: 42x35x27CM (Approximately 16.53×13.78×10.63 inches.

Fabrication: PA6 Nylon with an aluminum profil.

45mm is a workable thickness (Height 64mm.

750 rpm spindle motor (12-36V); 24V: 10000 rpm spindle moto.

Spindle Chuck: ER11 Collet Spindle Chuc.

Spindle PWM speed: Support power can be adjusted from 0 to 100 percent.

Motor: Nema17 42 stepper motor, 1.3A, 0.25N.m, 1.3A, 0.25N.m, 1.3A, 0.25N..

Power source: 24VDC power adapter with 5.6A current (110-240VAC input voltage.

GRBL1.1f firmware, offline work support, upgrade version of the control board with shell and fan for the best dust proofing, cooling, and service life extension; upgrade version of the control board with shell and fan.

USB connection (Windows XP, Windows 7, Windows 8, Windows 10, and Linux) PC-USB connectio.

GRBL controller is a piece of software.

Processing precision is approximately 0.2mm.

Stainless steel screw with 4mm lead and double copper nut backlash (T8 T-screw).

The GRBL 1.1f Control Board is comprised of the following components.

Specification.

1.Use of a USB connection (USB-CH340.

2.Software: GRBL controller, UniversalGcodeSender (universal Gcode generator).

3.Input voltage ranges from 12 to 24 volts.

4.The Atmel 328P is the master chip (arduino nano.

MOSFET (recommended voltage is 24V, current is within 10A) for the spindle drive chi.

6.PWM speed of the spindle: Supporte.

7.Support stepper motor: 12V, maximum current of 2A or less is recommended within 1.5A of the stepper motor’s maximum current, as well as additional hea. (Any stepper motor 42 or 57 will do..

8th, power interface: 5.5-2.5mm direct current interfac.

It was very simple to put together, and once you get a handle on how the software works, it’s fantastic. I have to make use of two different software packages. I created the drawing in Easel and saved it as a GCODE file. I then downloaded UGS (Universal Gcode Sender) and used it to upload the GCODE (.nc) file to the CNC router, which worked perfectly. At the very least, they are all completely free. I am extremely pleased with my purchase.