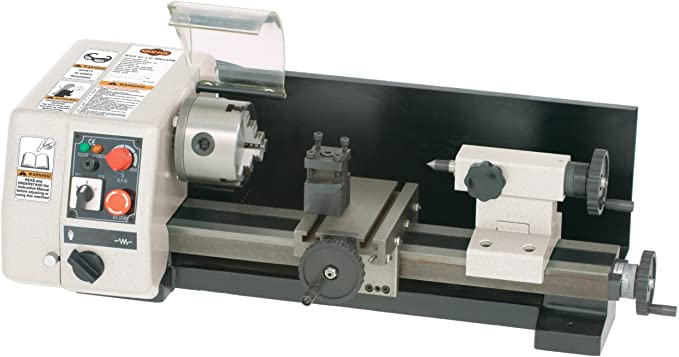

4 hex wrenches, spindle speed range of 100-2000 RPM.

MT #2 spindle taper and MT #1 tailstock taper are both available.

Wrenches with two ends, such as a double ended wrench or a socket head wrenc.

Included are an oil cup and a stand.

3 external jaws and a chuck key are included.

This Model M1015 Mini-Lathe is an excellent choice for anyone looking for a long-lasting, well-designed machine that can be stored in a small space. This Mini-Lathe provides model makers, toolmakers, gun hobbyists, and weekend machinists with a cost-effective way to produce small precision parts, threaded parts, fittings, and dies in small quantities. Made in a factory that is certified to ISO 9001.

I’m considering taking these people to court for the complete fabrication that is this advertisement, and I’m half-hearted about it.

There are ZERO technical specifications for this machine that are valid. Despite popular belief, the spindle’s centerline (i.e. the swing) is NOT 6 inches.

In fact, there isn’t a single imperial fastener on the machine that I was given to work with. In spite of the fact that all labels and reference material state otherwise, the lead screw is NOT 16TPI.

It’s a complete and utter joke, and it’s by far the worst thing I’ve ever purchased from Amazon, bar none.

ANOTHER REVIEW FROM BEFORE.

To be completely honest, writing this review makes me feel sick to my stomach. It does not make me happy to be sitting here and documenting the poor construction quality. I sincerely hope that this is a matter of quality control and that not all of the lathes they sell are constructed at such a low quality level.

First and foremost, the spindle on the unit I received was so badly constructed that it fried the bearings within two months of receiving it. I’m talking about _cooked_. Oh, and it’s FRAUDULENT. There is a *bend* in the spindle, to put it another way. The bearings were completely out of options. The point of using tapered roller bearings if you’re going to weld two pieces of shaft together and hope no one notices is a bit of a moot point.

Second, the 3/8″ spindle bore is intentionally smaller than the standard size. The spindle shaft itself measures more than 20mm in diameter, and the majority of the spindle bore measures at least 1/2″ in diameter, if not 5/8″. For the time being, I’m far too annoyed to actually measure it, but suffice it to say that there is absolutely no reason why it shouldn’t have at the very least a 1/2″ through hole bore.

It’s possible to see in one of my photographs that the actual spindle nose has been chowdered up. I’m not going to bother with a finish pass, I’m just going to let the chatter continue. I understand that I’m not paying for a world-class machine here, but I’ve yet to come across another machine in this price range that is of such poor build quality as this one.

If the gibs had been machined well, or at the very least to a reasonable tolerance, the dovetail ways would have been a nice finishing touch. Due to the fact that both ends of the Z and Y gibs were out by at least 0.010″, actually operating the machine was quite difficult.

The actual speed control circuit and motor used is, to put it mildly, a joke. On top of all of that. Essentially, you’re getting a dremel motor with a crazier speed control. Literally. The motor in my machine is a brushed, 110V direct current motor. Yes, you read that correctly – DC. It is also controlled by a circuit that was created by what I can only assume is a bipolar electrical engineer, which I find interesting.

Do yourself a favor and wait a few more days before purchasing any other machine. Seriously, I wish I’d done it sooner.