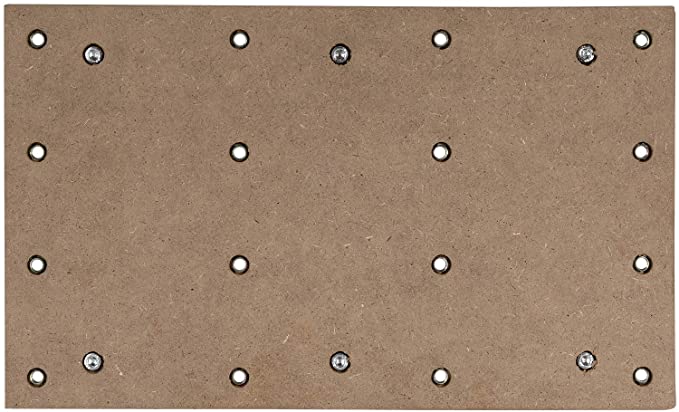

One of the things that goes above the router’s table is a piece of scrap wood called a “spoilboard. It can protect the router table from damage, as well as be a surface that can be used for workholding.

It’s made of MDF (Medium-Density Fibreboard). MDF is very dense, which means it is heavier and more durable. How big are these things? They’re 30 x 18 x 1.2cm (11-4/5″ x 7″ x 1/2″).

All 3018 series CNC router kits will work with this.

When cutting or carving wood, this tool is usually used. In order to keep your CNC table from getting scratched by cutting tools, you cut on the MDF spoilboard. It can make sure that the cutting material stays in place, which means that the cutting will be more precise.

If you have 45mm of total Z axis distance, but you need some of that to move around. You might need 10mm for the spindle to rise before it moves.

There are 45-10-13, or 22mm, that your work piece can be thick. If you need that space because you use the z-probe that is 13-14mm thick, we’ll go with 22-13mm or 9mm for how thick it can be.

So why do all of the 3018 CNC machines have such a small amount of space in the Z Axis? That’s just crazy. I had problems (without this) putting a piece of 3/4″ wood in the machine and having it z-probe. This leaves the machine at Z=13+8 (the height it moves up after probing), or Z=21. When you add in the 18.75mm for the wood thickness, you’re now at 40mm. During the first move, the vcarve moved up, hit the zstop, and died. If you move the z down too close to your work piece, it will move up about 10mm and start the engraving and work. But you can’t leave it where it defaults to.

A lot of the time, this makes it hard to do anything with any thickness on the machine, which would be its main use case (I would think).

In any case, with so little head room, shaving this down to level it, and then putting a 3/4” piece of wood on top, you’re out of space and the machine is hard to use.

I had to give mine back. Maybe if you used double masking tape with CA glue inside to hold it down instead of nuts, it would work better and be less expensive. You’d only need 4 screws to hold it down and countersunk holes to hold it down. Which would save money and be useful, too.

There is a chance that it might work for someone who is in a unique situation.