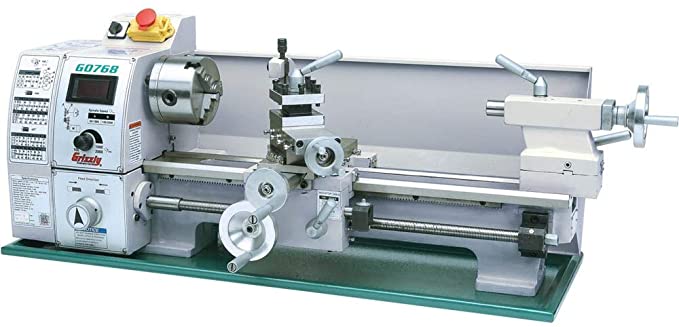

Motor: 600W (3/4 horsepower), 110V, direct current, 10.

Bed 8-1/4″, cross slide 4-5/8″, total swing over: 8-1/4″.

15-3/4″ is the distance between the two centers.

Spindle bore: 0.787″ (20mm), taper: MT#3 Spindle bore: 0.787″ (20mm), taper: MT#.

Spindle speeds range from 50 to 1000 RPM in the low range and 100 to 2000 RPM in the high range.

Latest update: After three years of use, I can still say that I am pleased with it; however, some circumstances have arisen that make it necessary for me to purchase a larger lathe to accommodate my needs. At low speeds, the motor’s torque is not particularly impressive. It is not noticeable when cutting smaller parts because the motor is in a favorable part of the torque / speed curve for the motor at that point in time. I’ve had difficulty cutting larger pieces at slower speeds because there isn’t enough low-end torque available.

The rigidity of the lathe is not particularly high.. I’ve had instances where the compounds slide has come loose, causing a great deal of chatter. After everything is tightened up, it cuts like a dream for a short period of time. However, after machining some 4″ diameter 416SS, it appears that everything has become more loose. To be clear, I made the parts to exacting tolerances of 4.000″, so when she is tight, she runs exceptionally well.

Despite this, I am still pleased with the lathe in general and would recommend it to anyone who does not have space for a larger lathe. If you have the space, you’ll want to invest in a larger lathe. I just don’t have the time right now.

The original review was published on April 25, 2017. I’ve had my lathe for a month now, and I couldn’t be more satisfied with it. The main reason I chose this particular model was that I did not have the necessary equipment to lift or the space to accommodate a larger lathe. For the same price, I looked at the G4000, which had a significant increase in weight and a significant reduction in features (no variable speed, no cam-lock tail stock, no reverse threading) while having only a slight increase in the amount of movement it could make. In a perfect world, I would have been able to deal with the weight and size of the G0602, but unfortunately, that was not the case. My wife and I were able to easily lift this lathe from its extremely well-constructed crate and place it directly on the bench without exerting excessive effort.

The lathe is a good size in terms of overall dimensions. My surprise at how large a piece I can fit into the lathe without having to go to extremes has been gratifying. 7X14 lathes have proven themselves in this department, and the extra space on the G0768 makes it even easier to complete the task at hand. The lathe had done an excellent job of cutting through some extremely hard stainless steel with an HSS bit that had been properly sharpened. Because of the high speed of the lathe, I have been able to make excellent use of the inexpensive carbide cutters (2000 rpm without modification). When one is a beginner machinist, the variable speed is a godsend because it allows you to get out of trouble very quickly and change to a more appropriate speed in a flash. My carriage has been rammed, and the belts slipping have helped to mitigate the damage ( percent -p).

The fit and finish of the lathe are both excellent in every respect. In the process of dismantling the lathe and cleaning the ways and slides, I discovered that there was very little grit as I had anticipated. You have been forewarned that the bottom of the slides is as sharp as a razor; proceed with caution.

This lathe is ideal if you require a lighter lathe that can be moved more easily up and down stairs or into and out of vehicles, such as a truck. This is also an excellent first lathe, although the less expensive 7×14 lathes would be a better choice because, once you get into machining, you will quickly find yourself wanting a larger lathe, no matter what size you start with at the beginning. If you decide that machining is not for you, you won’t have lost much money in the process. If weight and space are not important considerations, there are larger lathes available for not much more money that would be more suitable over the long term, such as the G0602.

It is a great machine for those who are just getting started in their machining careers because it has some excellent features and can be customized in a variety of ways. I recently purchased a milling slide for this lathe and I am dreading the prospect of drilling and tapping holes into my cross slide and cross slide chuck. With a vertical milling head, it’s the same lathe as the G0768, and the cross slide from that model is compatible with the G0768. In the G0769, the s cross-slide has t slots milled into it to hold the work in place while milling is performed. It will be extremely useful to have these t-slots to hold my milling slide, which will allow me to mill small items on the G0768 without the hassle and expense of using the G0769’s milling head.

The G0768 is an excellent candidate for conversion to CNC. I’ve seen a number of kits designed specifically for this purpose, but I doubt I’ll be installing one until I’m more comfortable with manual machining techniques.

For the record, the service provided by Grizzly was outstanding. Upon arrival, the lathe was carefully packed in a sturdy crate (which was immediately claimed by my wife lol). Saia’s delivery was flawless in every way. My wife accepted the delivery from a lift gate truck driver who had previously coordinated with her the precise time at which it was to be dropped off. The driver helped her by unloading the crate and putting it in the garage. He was extremely professional and courteous throughout the entire process.

While I was thoroughly inspecting every component of the lathe, I discovered that the second set of jaws for the three-jaw chuck did not fit correctly. I contacted Grizzly’s technical service department, and they promptly sent me a replacement set at no charge. The second set was delivered in a short period of time. Grizzly also carries a complete set of spare parts for the lathe, which you may not consider necessary at first (as I did), but which will become necessary if you decide to make modifications to your machine but are afraid to do so for fear of damaging your equipment. If I wanted to add some other types of tool posts to the compound slide, it would have necessitated significant modifications that would have prevented me from reverting to the original tool-post holder in the future. Grizzly has the replacement in stock, which means I can use my existing compound slide to machine the new one without sacrificing my ability to revert to the original configuration if the modifications don’t work out as planned (or as needed). When I’m making significant changes to the machine, it gives me a great deal of peace of mind.

The precision with which the lathe operates is impressive. Using my dial indicator over an 8″ piece of precision ground steel, I get absolutely no change in my dial indicator linearly. Without truing up the chuck, I get approximately 0.002″ of run out. The tool-post, compound-slide, and cross-slide are all extremely rigid, and there is no play on the dial-indicator, which is much better than I had anticipated. I am very pleased with this product. It is possible to tell when you have accidentally cut another thousandth of an inch more than was intended because the dials on the slides are accurate. Your part is one thousandth smaller than it should be because of this (ask me how I know lol).

The face-plate is extremely attractive. I was able to mount flanges without any issues, and the machine runs extremely straight.

The tail stock is one of my favorites. It is fully adjustable in all directions, but it did not require any adjustments because it was shipped from the factory in perfect condition. The cam-lock action is a must-have feature. This lathe has an excellent tail-stock, which I didn’t realize how much it would have to be moved before I started. When I checked the lathe out, I discovered that the dead centers were perfectly aligned with one another and required no adjustment.

Cons: I’m sorry, but I don’t have any to share. Because the compound angle adjustment requires pulling the compound slide all the way back, it is a hassle to get to the two cap-screws that lock the angle. In order to correct this, Teleger Music has already produced a video showing how to modify the compound slide (another modification I will perform on my newly acquired compound slide once it arrives; see how comforting it is to have spare parts readily available.

Due to the fact that you have to shimm the tools, the tool post is inconvenient (as are all of them). A quick change tool post, also known as a QCTP, has been ordered; however, the first one I ordered was an AXA, which will not fit properly. The 0XA QCTP is a good fit, but it will necessitate some modifications to the compound in order to be installed.

The motor appears to be underpowered, but I know that this is due to my poor tool selection. When I use a properly sharpened tool, I am able to cut through hard stainless steel with no problem at all. When using carbides, I can turn faster, but the lathe slows down by about 20%, but it still makes the cut on the first pass.

Even though the chucks are accurate and true, they are not smooth. To make them run more smoothly, I will be cleaning them up and optimizing their performance.

Overall, this is one of the best purchases I’ve made in a long time, if not the best. I’ll be posting videos of the unpacking and some of the maintenance items in the near future. I would be delighted to answer any questions you may have.

By the way, I have no affiliation with Grizzly, and I only purchased the lathe after much deliberation and deliberation.