How to change angle grinder blade is important know-how that every user should have to operate their tool safely and properly. If you don’t have any available factory or improvised keys, you can still change your angle grinder blade by hand. Learning how to replace a blade on an angle grinder is crucial know-how for every user as this replacement will eventually happen one way or another.

An angle grinder disc can be removed without the tool by pressing in the spindle lock to lock the disc and turning the wheel in an anti-clockwise direction. Now that we have covered how you can remove a disc without the pin wrench, let’s also go over how to remove a disc with the proper tool and how to put a new disc on the angle grinder. There you have it, all the possible ways to remove a disc from an angle grinder without the use of the tool that comes with the grinder.

We show you several ways of how to change an angle grinder wheel. Slip your new angle grinder wheel on, and reverse the process. My favorite way to replace an angle grinder wheel involves switching out the stock flange with a Hilti Kwik-Lock flange.

If you’ve bought your angle grinder second-hand and the spanners are missing, there are other ways to change the disc without the factory-made spanners. Turn the pronged spanner in the opposite direction of the disc direction arrow, located on the bottom, while using the wrench spanner to keep the disc from turning. Use the vice grips to keep the disc from spinning, and insert the screwdriver into one of the holes between the disc and the angle-grinder motor, meant for the spanner prongs.

The first sign that your angle grinder blade needs replacement is if it has worn down to the point where it is taking you significantly longer to cut through something than when the blade was new. Let’s go through a simple step by step process on how to change an angle grinder blade right now. If you don’t have the factory spanners to replace the blade, there are ways of replacing the blade on your angle grinder without them.

how to change cutting disc on angle grinder Related Question:

Can you change the blade on an angle grinder?

The blade of your angle grinder is held in place by a locking nut. Changing the blade requires this nut to be loosened and removed. This is usually done using a special two-pronged wrench. A wrench that fits the size and shape of your angle grinder’s locking nut should have been in the box when you purchased it.

When should I replace my angle grinder disc?

Always replace a cutting disc if it shows any signs of damage. This includes, but is not limited to visible cracks and chips or any signs of bending or twists to the wheel. Cut off wheels should be replaced when they hit their expiration date. This can be found imprinted on the metal center of the disc.

What tools use to remove the angle grinder disc?

A pin wrench is the required tool that comes with an angle grinder and is used to remove a disc. This wrench resembles a pitchfork and has two knobs on the end that you insert into the drive bolt to loosen the nut holes that attach to the disc.

How do you remove an angle grinder blade?

Use your screwdriver to remove the blade guard before you remove the blade. This will make it easier to get the blade off. Loosen the screw that holds the blade guard in place, or push the release latch on the blade guard to remove it.

Which way should an angle grinder spin?

Every right-angle grinder is marked with a directional arrow on the head of the grinder that indicates the direction the wheel is rotating when in use. For optimal performance, it’s important to orient the cutting wheel so it rotates into and pulls itself into the workpiece rather than rotating away from the workpiece.

What is cutting disk?

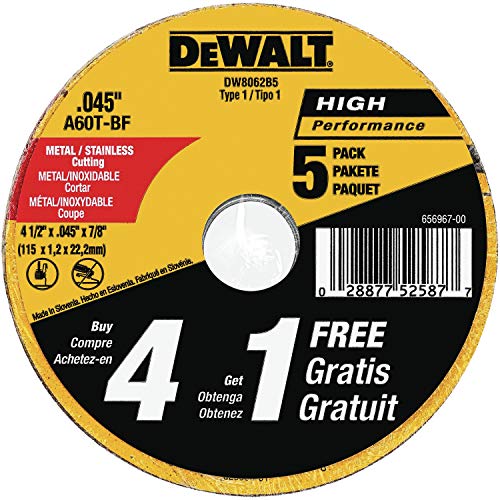

Often cutting discs, also known as cut-off wheels, are made from a solid abrasive disc. These discs are often used for cutting metal; they are composed of an abrasive mix of grit and adhesive that is formed into a thin, rigid disc with fiber webbing running through it for strength.

Can you put a cut off wheel on a grinder?

While die grinders may look similar to cut-off tools, they are not. They are unguarded tools without flanges and should NEVER be used with cut-off wheels. It is simple to remember: if the tool does not have a guard, do not use a cut-off wheel.

How long do grinding discs last?

1 – Cutting and Grinding Discs Have Expiry Dates. This date is generally printed on the centre ring and is at a maximum three years from the manufacture of the disc. On smaller discs which lack a ring, this date may be printed on the label or even the disc itself.

Can you use a cut off wheel on an angle grinder?

Usages. You can use cut-off discs for cutting metal bars, metal tubes and small pieces of metal sheets and plates. You can also cut out welds with them. For shortening the length of various bolts, it is also a good idea to use an angle grinder and a cut-off wheel.

Is there anything an angle grinder can’t cut?

The inspiration behind this creation is the natural defense mechanisms used by shells, grapefruit skins, and fish scales that makes them resistant from the attacks of various sea creatures. The material, named Proteus, cannot be cut using either angle grinders, drills, or high-pressure water jets.

What is a metal cut off disc?

Cutting wheels (aka cut-off discs) are an abrasive tool used for fast cutting of materials like metal, concrete, and stone. Their portability allows the operator to move around freely with it and maneuver their tools from different angles to easily cut a material.