Usually, lumber and logs that lie within a diameter range of 16 to 18 inches are able to be cut under a bandsaw mill. At this stage, we will take you through a 7 steps guide on how to cut lumber with a bandsaw mill. Once done with steps 1 and 2 of how to saw lumber with a bandsaw, it’s time to make the first cut on your lumber.

There are a handful of techniques that woodworkers use for processing lumber with a bandsaw mill. You have to saw the log at opening face almost half path. So that’s some basic techniques and approaches to safely use a bandsaw mill for lumber production.

The height where I made my first measurement won’t change as I raise the small end of the log. I don’t own a bandsaw mill but I figure my opening cut is going to be not much different so…. “Log 12″SED flaring to 18”. The main reason I do the horns first is because many times the log turner will get under center of the log making turning a pain for me, I like to get what I call the trouble out of the way first, I have in mind what direction I am going, but the next two cuts will ultimately determine how I get there.

You can save time by properly preparing your logs before they go on the mill. Trim the bell of a butt log as close to the diameter of the rest of the log as you can. If you are cutting logs from the trees in someone’s yard, then grab your metal detector.

It’s surprisingly easy to mill short, small logs into furniture-grade boards, right in your own workshop, all without special equipment. “I’ve had good results using two methods for milling lumber from small logs in my shop. The simplest involves a hydraulic wood splitter – the kind used to turn logs into firewood. Clear, straight-grained, easily-split species of wood are easy to cleave into board-like billets. Most firewood splitters handle blocks up to 24” long, so when you find a good log, cut blocks to this length, even if you’re making your firewood shorter. “Regardless of how you mill your micro lumber, drying involves the same process used with other kinds of rough lumber. No matter how long it’s been since your logs have been cut, the wood is still too wet for woodworking if those logs have not been sawn into boards. That’s why you need to promote air circulation on all sides of every board, and a household fan really speeds progress. Stack your lumber with 1/2”-thick strips of scrap lumber between each piece, then direct air flow over the pile.

how to cut logs on a bandsaw mill Related Question:

How do you cut wooden logs?

To cut your wood slices, we strongly recommend you have either a miter saw or band saw. These are the best saw options to use when cutting log slices, as they can make more precise cuts with the uneven nature of a log. They can also cut thicker pieces of wood than other types of saws.

How thick of wood can a bandsaw cut?

Band saws are the undisputed champ when it comes to cutting curves and slicing through thick material. Many small band saws can slice though lumber a full four inches thick, and bigger saws handle six-inch cuts.

How high can a bandsaw cut?

The resaw capacity is the maximum height (thickness) that can be cut. For the small shop furniture maker, go with 14″ as the minimum for a bandsaw, though 16″ is better. Those doing larger work might even want 18″ or 20″ machines. Just make sure you have a minimum resaw height of 12″ for versatility.

What are the three main ways to cut a log?

What many don’t know though is that there are three different method to cut wood to produce different results from the log and those are sawing, slicing, and using rotary.

How long do you cut logs for sawmill?

Care should be taken to cut the felled tree into lengths of highest possible value. Standard sawlog lengths usually run from 8 to 16 feet, with intermediate cuts at two-foot intervals.

What does chop your own wood and it will warm you twice mean?

“Chop your wood and it will warm you twice”. This saying is the starting point of many of our products. Figuratively, it means that if you work towards something, the journey itself can be rewarding. Literally, the act of chopping wood for a fire will make you warm up just as much as the fire will.

Should you let logs dry before milling?

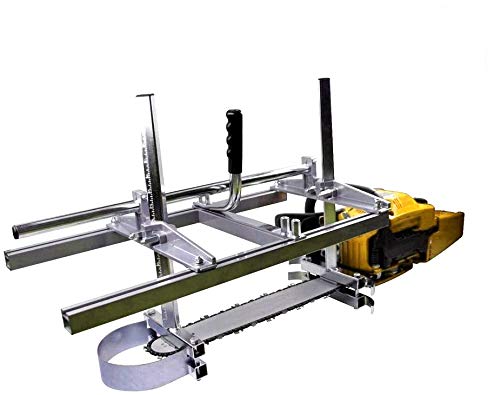

Summary: Logs should be milled for drying as soon as possible, and the ends should be sealed as soon as they are felled. A bandsaw mill will create less waste than a chainsaw mill. Logs can be sawn for grade, quarter sawn, or flitch cut.

How long does wood need to dry before milling?

Depending on the thickness of the lumber and where you live, weather and time of the year, it will take anywhere from 6 weeks to 4 months. Most lumber is in the 1” to 2” thickness and the time above applies to thicknesses.

Is it better to cut wood wet or dry?

Wet Wood Vs Dry Wood But wet wood is actually much easier to cut than dry wood. With dry wood lacking moisture content, more friction is created as the chainsaw chain comes into contact with the wood fibers. This friction results in the chain slowing down.