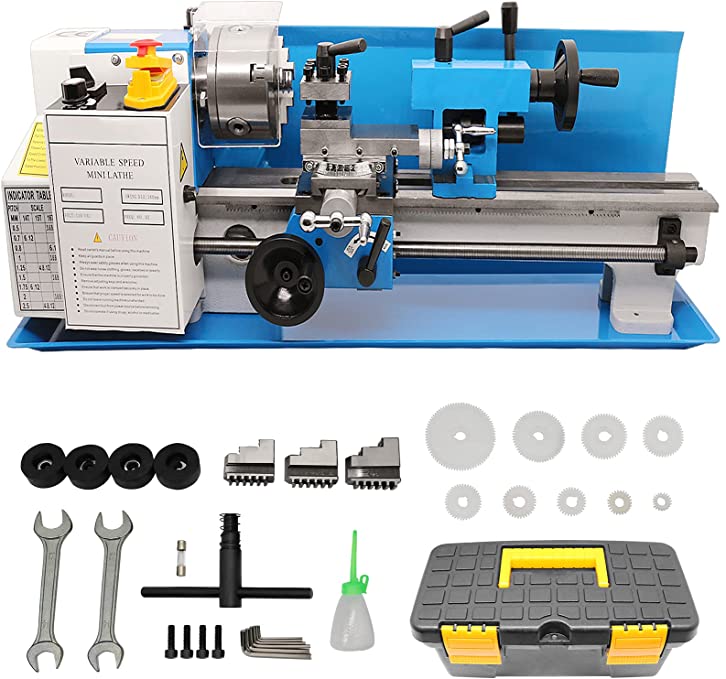

The construction is excellent, and the power is tremendous. The mini metal lathe is constructed of high-quality iron and is powered by a powerful 550-watt lathe motor. The use of high-grade iron in the construction makes it more durable when turning, drilling, threading, and cutting operations are performed. The use of two rails allows for smooth and durable movement. Design of nylon gears.

VARIABLE SPEEDS- The MT4 Spindle has a variable speed range of 0-2500RPM, and two speeds are available to meet the needs of different metal working applications. Low speed ranges from 0-1250RPM to 100-2250RPM. High speed ranges from 100-2250RPM. The metal lathe is equipped with a safety switch and an emergency power off feature; to turn off the power, simply tap the red cover on the safety switch.

The precision design of power metal lathes allows for a large center distance of 350mm (13.78″) and a swing over bed of 180mm (7.09″), as well as a large spindle bore of 21mm (0.82″). A precise self-centering 3-jaw is provided, which can be used to hold a variety of round or square cylindrical materials with stability. The metal lathe is designed to be used both forward and backward.

“PROFESSIONAL COMPOUND REST” is a 4-way quick change tool post that allows you to use up to four common turning tools at the same time. With a slight turn, you can unlock the lock and swap out the tool. Tool post adjustments are made by turning blade adjustors with accurate scales clockwise or anticlockwise on their respective shafts.

EASY TO USE- By releasing the fix handle, you can move the tailstock forward and backward; the MT2 dead center can be adjusted by releasing the quill lock and turning the tailstock handwheel.

It is possible to move the Cross Slide freely by moving both the horizontal blade switch to the left and the turn handle.

To fix the handle and dead center, the two holes on the top and side of the handle can be rotated with a wrench to the desired positions.

TLDR.

Price is one of the advantages.

Drawbacks: Fit and finish, as well as overall qualit.

Early Recommendation.

A mounting bolt on one of the mounting bolts was over torqued or cross threaded, and it could not be removed because it was in a crate. Despite using locking pliers to remove the remaining stem, the bolt head sheared and could not be removed. It will be necessary to drill it out. The tail stock was loose and slid around, but it did not appear to be causing any damage to the vehicle.

The overall quality of the fit and finish is poor. Paint has been sprayed all over the place ( see pictures). There is a lot of burs on the castings that has not been ground off. Labels are applied incorrectly.

As measured on the outside of the chuck, the 3 jaw chuck is 5-6 thousandths of a thousandth out of true right out of the box. I’m not sure how true it runs on the part at the moment because I don’t have any precession ground stock to compare it to.

The included tool holder is a piece of trash, but I intend to replace it as soon as possible with a quick change.

There is a significant amount of backlash in the dials, and the main left-right position dial moves the cross slide far more than I would have liked it to ( I will likely make a gear reduction for this.

Overall, it appears to have been constructed with QC second/thirds in mind for the various Sieg type clones. It will almost certainly necessitate disassembly cleaning and the use of stripper to remove excess paint, at the very least. It is likely that some new bearings and modifications will be required to make the machine more precise. If you don’t mind a lot of work, you can turn it into a very fine machine with a couple of days of effort and an additional $50-$100 in parts to tighten up the tolerances on the components. (It’s a 3-3.5 star out of the box, but a few minor upgrades will elevate it to a 4-4.5 star rating. The manufacturer simply scrimped on parts and quality control)