02-17-2019, 5:42 PM #1 I just got my first bandsaw a Rikon 10-324 and need it pick up some blades. Looking at cheaper blades till I get a feel for how I will use the new bandsaw Then buy better blades next time. JKJ. 02-19-2019, 11:42 AM #11 I’m sure there are other bandsaw blade comparisons online but this might help with comparing Timberwolf to sawblade.com blades.

If you can arrange it, have a close look at the weld before you buy from Olson. Maybe I just got unlucky but I bought 3 Olson blades when I first got my bandsaw and they were truely awful due to misalligned welds. If I’ve still got them I’ll take a picture of the weld on the Olson 1″ blade.

Michael Fortune wrote an article in Fine Woodworking suggesting that you use only one bandsaw blade for nearly everything. Of course before I read that article, I was more than satisfied with my Lenox blade, but I found this Olson blade, so I thought I’d give it a shot. My Lenox blade still cuts smoother and straighter, so I think it is a better choice for the primary blade on the saw, but this blade might be particularly useful for cutting up logs or other rough work.

olson bandsaw blade reviews Related Question:

Where are Olson band saw blades made?

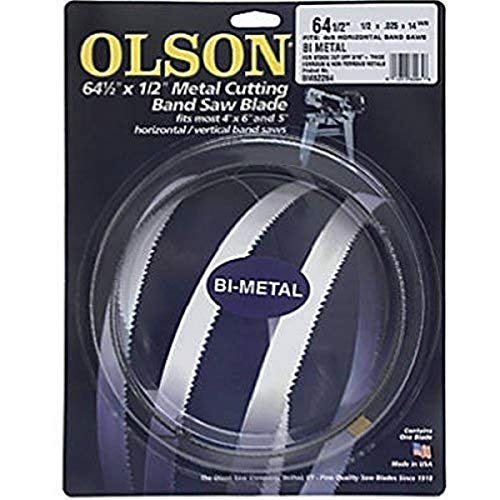

This reliable blade is for cutting non-ferrous metal. Made in the U.S.A.

How long should a bandsaw blade last?

On average your bandsaw blade should last 6 months to as long as a few years depending on what your cutting with it. Make sure to match your blade strength and quality to the project and material your cutting.

Is a wider bandsaw blade better?

The wider blades are stiffer overall (more metal) and tend to track better on the band wheels than narrow blades. When cutting thicker material, the wider blade has less ability to deviate because the back end, when in the cut, helps steer the front of the blade, especially if the side clearance is not excessive.

What is a hard back bandsaw blade?

The Hard-Back Carbon Steel bandsaw blade is designed with higher performance standards in mind and based on the materials this particular blade is able to cut. Hard-Back Carbon Steel Blade’s back and teeth are heat-treated, creating a higher tensile strength that allows for straighter cuts at faster speed rates.

Where are Olson scroll saw blades made?

Olson Saw Company continues to manufacture in Bethel CT, making a wide range of band and scroll saw blades, band saw and power scroll saw accessories, handheld saw frames and other wood working accessories.

Is more TPI better?

Woodworkers quickly learn that the number of teeth-per-inch (TPI) on the blade has a big impact on the quality of a cut. The general rule of thumb is “the more TPI, the smoother the cut.” The true answer, however, is just a little more complicated than that, as you’ll learn once you understand how saw teeth work.

How do I choose a bandsaw blade?

Use coarse tooth blades (2 or 3 TPI) for re-sawing and cutting thicker materials. For general wood cutting duties in typical 3/4″ material, use a 4 TPI blade for coarse, fast cutting and a 14 TPI blade for slower, smoother cutting. A blade in the 6 to 8 TPI range provides good general-purpose performance.

Are bandsaw blades worth sharpening?

Since a carbide-tipped bandsaw blade will cost well over $100, spending a third of the cost of the blade (or more) to get it sharp and working like new again can make financial sense. However the majority of bandsaw blades, the Wood Slicer included, are not worth spending money to have sharpened.

How many times can a bandsaw blade be sharpened?

It often makes sense to replace a dull blade with a new one, but you can sometimes get the best value out of merely sharpening an old blade instead of replacing it altogether. You should typically be able to get two to three sharpenings before you need to change your blade completely.

How many times can you sharpen a sawmill blade?

You should be able to sharpen your blade two or three times before needing to replace it, but sometimes breakage happens. Blade breakage can result from a range of situations. Common causes of blade breakage include: Dull teeth.

How tight should my bandsaw blade be?

The blade should deflect no more than 1/4 in. A good place to begin is to tension the blade until the meter reads proper tension for the next wider blade. For example, if you’re tensioning a 3/8-in. blade, I would set the scale to 1/2 in.

What is a 3h bandsaw blade?

Description. These are excellent-quality steel bandsaw blades that excel at ripping thick stock and resawing, and are also suitable for roughing blanks for carving or turning. The coarse 3 tpi hooked teeth power through hard woods and difficult grain, and have deep gullets for clearing sawdust.

What type of bandsaw blade is best for resawing?

Resawing involves making rip cuts in the face of a wide board. So just like you would on the table saw, you’ll want to select a blade with fewer teeth per inch (TPI) than the blades you use for crosscutting or cutting curves. For most 14″ band saws, a 1 ⁄ 2 “-wide blade with 2-3 TPI is a good choice.

What’s the difference between bandsaw blades?

Bandsaw blades differ in thickness, width, length, and tooth configuration. Length varies by machine, but the size of your saw’s wheels typically determines thickness and width: Smaller machines (9–12″ wheels) need thinner blades to prevent breaking the welds. They also accept only narrow blades, often 1⁄ 2 ” or less.

Can you cut stainless steel on a bandsaw?

Bi-Metal blades are able to cut hard materials like Stainless, D-2, and dye’s. A bi-metal saw blade won’t easily fail due to its high-speed edge performance.