Produced from Fine Grain Cast Iron (FC25); lead screw with a trapezoidal threa.

Jaw deflection is less than 0.002″ at 2,000 lbs. clamping pressure; jaw surfaces are square to 0.002″ tolerance.

Replaceable jaw plates; solid iron construction with a stress-relieved desig.

By using a magnetic insert, it is possible to attach punches or other tools to the end of the ram.

Description of the Produc.

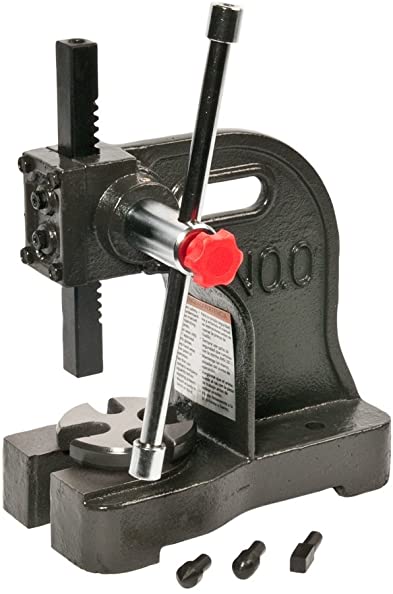

Arbor presses such as the Palmgren 12 ton Arbor Press provide the heavy force required for riveting, squeezing, punching, bending, and other pressing operations. The anvil, which is made of machined steel and can be removed, provides accurate work support in four slot positions. The depth stop is securely clamped to the ram and can withstand the full force of the ram. The depth of the ram stroke is precisely controlled by a fine adjustment screw with a lockable locking mechanism. 3 x 3 x 3 inches are the dimensions of the rugged steel ram, which is driven by a machined piston. With the help of a magnetic insert, it is possible to attach punches or tools to the end of the ram. With one end solid and the other end featuring a hole and magnet to hold bits and tools, the ram can be used in either direction. The rugged strength provided by the cast-iron construction is ideal for more demanding jobs. There are predrilled holes for mounting on a bench or pedestal, and the base has been machined to accommodate the three bit set that comes with the kit. The bit set includes three bits: a pointed bit, a round bit, and a square end bit, as well as a steel anvil that can be removed. The removable anvil has a diameter of 3 12 inches and is made of steel.

The Manufacturer’s Statemen.

With a 4′ Palmgren cradle style angle vise, you can quickly adjust the angle of your work between 0° and 90°. Width of the jaw: 4. Jaw Opening: 4′ Jaw Depth: 1-1/2′ Jaw Depth: 1-1/2. The base measures 7-3/8′ x 7-9/16′. Produced from Fine Grain Cast Iron (FC25); lead screw with a trapezoidal threa. At 2,000 lbs. clamping pressure, there is less than 0.002′ jaw deflection. Strong cast iron construction with stress-relieved design; jaw surfaces that are square to 0.002. Jaw plates that can be replace. Pin stops are placed every 15? to allow for quick angle set-ups. Vises can be secured at any angle thanks to a heavy-gauge steel cam locking mechanism. Scale indexed in 1? steps from 0? to 90? from 0? to 90. The fixed jaw is grooved both horizontally and vertically to hold round stock securely in place.

It’s a straightforward arbor press. This 0.5 ton baby isn’t going to change the world; it’s just a simple rack and pinion + lever advantage tool that’s typically used for joining or moving press fit metal components. For example, arbors, shaft-bearing bearings, and so o. Users who are creative can come up with a slew of other applications in which controlled downward force is required rather than brute hammering. A sturdy bench or stand must be used in conjunction with it in order to apply full force. For some applications requiring additional clearance, a hole in the bench beneath the anvil may be required. It’s a clever system. If you want to drive railroad spikes, you shouldn’t buy a tack hammer..

This tool is completely satisfactory in terms of construction and materials, as well as for use within its intended capacity. The rack can be used with either a solid or a hole end. A depth stop clamp for the rack is included, but it is not visible in the picture. It is never intended for the holding magnet in the hole end to be subjected to press force. The supplied tools should be placed against the square rack end rather than against the magnet. When designing tool holders, keep your intended application in mind.

In its class, it offers good value at a reasonable price. I recommend it for all hobbyists and/or small prototype machine shops, whether they are large or small. Any other light pressing operations that can be thought of are also possible.