Cut Cedar, Walnut, and Oak into Lumber that is of the Best Quality.

Mill-Cut Beams or Lumber from 0.5″ to 13″ thick and 36″ wide are made by this company.

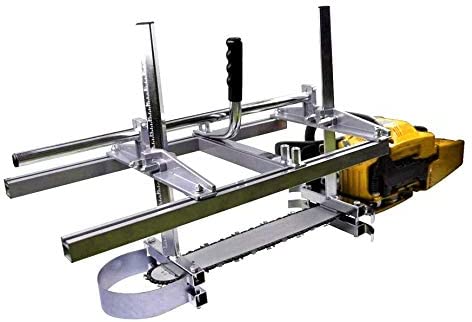

Attaches to the saw without having to drill a hole in the metal bar.

Sizes: 14″ to 36.

Portable Chainsaw Mill: CARMYRA made a 36″ Chainsaw Mill that can be taken with you.

CHAINSAW BAR 14 INCHES TO 36 INCHES CAN USE IT.

This is a high-quality product that comes with a 30 day money back guarantee.

A fast and easy installation. 7.5KGS Chainsaw Mill Portable Chainsaw Mil.

NOTE: The chainsaw and guide bar are not part of the package.

Bar length from 14″ to 36.

It’s made of aluminum and steel.

1PC Chainsaw Mill + 1SET Putting Tool + 1PC USER MANUA.

Effective and versatile 36″Mil.

Lumber planks are cut. Height and width can be changed.

Attaches right to your chainsaw bar.

I bought this mill so I could make wood for wood shop projects. You can’t buy slabs that are thick enough for what you want to do at the store near you, so you decided to make your own instead. This mill does a great job.

With a 32-inch bar, I have it on my Stihl 461. My friend told me to buy a ripping chain for milling. I did, too, and he thinks you should too. For example, the standard chain should have a cutter angle of about 30°, but the ripping chain only has one that is only 10° wide. Flat or angled files are also used to sharpen it, instead of a round file. A milling machine should not be used for general cutting.

There are no step-by-step instructions for how to put it together, but it comes with a diagram that shows how to put it together. Half an hour went by. Making it on the saw is easy. Keep in mind that you should clamp it where the sprocket/tip meets the bar, not the screws that hold the sprocket in place. Make sure you don’t do this because it will make your bar break and cost you money. There’s a 32″ bar that I can use for about 25 inches. In theory, I could get an inch more by taking the powerhead’s dogs off. That would be a lot of work for very little benefit though.

Milling should be done slowly. Make sure you support the slab with wedges or shims to keep the weight of the slab off of the bar. Let the saw do the work and don’t try to hurry it.

To make the first cut, I made a rail out of some 1x4s and 2×4 scraps. With screws on the bigger end, I first attach this to the log. Then I use a level on the end of the log to measure to the line I’ve drawn. On the smaller end, I shim up the rail to the same line as the other log end. I then set the mill to cut at that thickness, and I start with the first cut. For the next cut, the mill rests on the last one without the rail. YouTube videos show how this works.

All in all, I’m happy with this little mill. It is very good at cutting any thickness. My jaw dropped when I saw how heavy it was. It is very easy to use and very light. If you want to cut your own wood, I think this mill is great.