The technology to create durable band saw blades kept band saws from being a practical tool for the next many years. Woodworking band saw blades are generally made of carbon steel. While we primarily cut wood, band saw blades are available that cut many different materials.

Bimetal blades are made with a high-speed steel tooth structure attached to a flexible alloy steel backing material. Food grade stainless steel blades can be made from 420 stainless steel the preferred grade is either 440B or a proprietary grade. These blades last up to 10 times as long as traditional milled saw blades.

Selecting a band saw blade involves many variables, but blade type and tooth configuration largely depend on the material being cut. Unfortunately for most band saw users, no single blade can cut every material encountered in daily shop life. Tracking cost per cut over time, including blade cost, labor, downtime, and other wastes, is a good way to judge the success of a new blade that is put on the saw.

The backing for carbide tipped blades is made of a flexible spring steel. High speed steel tooth tips combined with flexible alloy steel backing material results in band saw blades that are the most cost effective choice for most metal sawing applications. The reason is simple: old circular saw blades aren’t worth anything because they’re made with carbon steel.

In this guide, we go through the complete process-selecting the right blade, breaking it in and using it, and looking after both the blade and band saw itself-to help you get the most out of your band saw and blades. Carbide band saw blades are ideal for cutting materials such as high-nickel alloy steel , HASTELLOY, titanium, MONEL, and INCONEL since they are able to withstand greater amounts of heat and maintain their edges for longer when used to routinely and continually cut especially hard metals. We supply band saws from leading manufacturers like HYD-MECH and are a Certified Master Distributor for original Lenox saw blades in both Canada and the US. Contact us today to discuss your needs, or shop for Lenox bi-metal band saw blades online!

As a general rule bimetal blades will cost about 2.5x a standard flex-back blade and last about 3-4x longer in metals, saving time and money. “Carbide tipped saw blade teeth are very hard and often used to cut exotic alloys and metals including inconel and titanium. They are also popular when cutting large aluminum or fiberglass cross sections to save time and prolong blade life. Because carbide tipped blades usually have a wide tooth spacing they are only designed to cut fairly large solids(3″+ min. A diamond grit band saw blade will cost about 2-3 times the price of a carbide grit blade but will last about 5-10 times longer on the correct applications.

what are bandsaw blades made of Related Question:

What type of steel are bandsaw blades made of?

Carbide (or carbide-tipped) band saw blades are ideal for cutting materials such as high-nickel alloy steel , HASTELLOY, titanium, MONEL, and INCONEL since they are able to withstand greater amounts of heat and maintain their edges for longer when used to routinely and continually cut especially hard metals.

What material are saw blades made of?

Tempered, high-grade tool steel, alloyed with certain other metals, is the main material used to manufacture the saw blade. Handles used to be made solely of wood, but modern tools can also be made with molded plastic.

Are bandsaw blades spring steel?

How are band saw blades made? This material consists of two kinds of metal: The alloyed spring steel creates the body of the band saw blade strip, a high speed steel wire is welded to the top of the body. When teeth are milled into the bimetal strip, the High Speed Steel material creates the tips of the teeth.

Are saw blades hardened steel?

Steel needs to be hard enough to cut through things like tree trunks. To cut through things, the hardness of the saw blade will play a pivotal role. Table saw blades are hardened to ensure that they cut through things with relative ease. You can make the table saw edges using various kinds of steel.

Can a bandsaw cut hardened steel?

Carbide band saw blades provide high wear resistance and toughness when cutting a variety of applications such as: case hardened steels, spring steels, high speed steels, nickel based alloys, case hardened steels, composite graphite, high nickel alloys, titanium, inconnel, and other exotic metals.

What’s the difference between bandsaw blades?

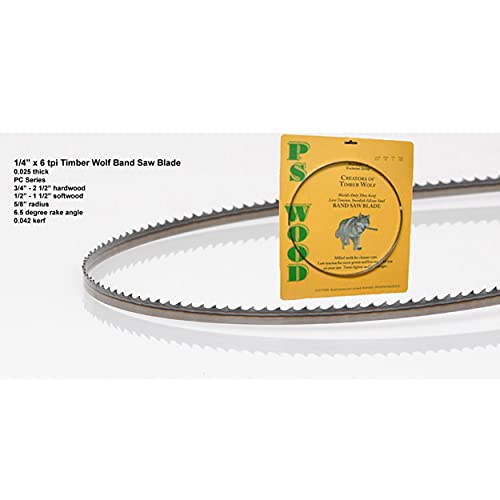

Bandsaw blades differ in thickness, width, length, and tooth configuration. Length varies by machine, but the size of your saw’s wheels typically determines thickness and width: Smaller machines (9–12″ wheels) need thinner blades to prevent breaking the welds. They also accept only narrow blades, often 1⁄ 2 ” or less.

What metal is used for saw blades?

Saw blades are made from many different materials. Steel saw blades are relatively inexpensive and suitable for cutting wood. Most band saw blades are made of steel. High-speed steel (HSS) saw blades are harder than regular steel blades and stay sharp for longer periods of time.

What kind of metal is a hand saw made of?

Tempered, high-grade tool steel, alloyed with certain other metals, is the main material used to manufacture the saw blade. Handles used to be made solely of wood, but modern tools can also be made with molded plastic.

What are bimetal bandsaw blades made of?

Bimetal band saw blades are aptly named because they are made from 2 different metals – a flexible carbon steel backer and a much harder tooth edge which is attached to the backer. Usually this tooth edge is made from M42 Cobalt steel which is why you will often hear the term M42 Saw blades in reference to bimetal.

Can you cut metal on a wood bandsaw?

Band saws are not suitable for cutting very thin sheet metal; a rule of thumb suggests the metal to be cut should be thicker than the depth of 3 band saw blade teeth, however they are excellent for cutting thin walled profiles such as box and angle.

What band saw blade for stainless steel?

When cutting Stainless steel, it is recommended that either a Carbon or bi-metal saw blade be installed. Carbon saw blades are an economical choice and used to cut different types of non-ferrous materials. This type of blade cuts soft materials like wood, plastics, and brass.

Are saw blades already hardened?

This is the entire process of hardening blades, and most circular saw blades have at least hardened teeth. High-quality circular blade are made completely hardened and that’s what you should looking for. You might also find bi-metal blades that have a tough body with an outer rim of hardened steel.

What are the three main types of bandsaw blades?

There are three basic tooth styles in bandsaw blades: regular, skip and hook. Regular tooth blades have proportionally spaced teeth and are ideally suited for general-purpose cutting and contour sawing. Regular blades are ideal for cutting thin materials with a fine finish.

Can you cut hardened steel with a hacksaw?

If a clean cut is desired when cutting through hardened steel, or if the steel’s hardness must be retained, a fine toothed hacksaw will work wonderfully, though the process is long and will require a great deal of intense effort.

What is a bimetal bandsaw blade?

Bimetal blades are metal cutting blades. They are used on band saws to cut carbon steel, tool steel, structural steel, stainless steel, pipes and tubes, die steel, angles and flat stock, and mixed metal applications.