If you have an unusual, custom, unique or vintage band saw you can choose from 2 new sizes:CB51010BL 1″ x 1″ x 1″ Cool Blocks or The SLAB CB-SLAB 6″ x 1-3/4″ x 1/2″ Customizable to fit various saws. To modify for your specific band saw: After carefully measuring the size of your saw’s guide blocks, saw each Cool Block to that exact size using a very sharp, thin kerf blade. CB-SLAB Contains 1 slab 6″ x 1-3/4″ x 1/2″ To modify for your specific band saw: After carefully measuring the size of your saw’s guide blocks, saw each Cool Block to that exact size using a very sharp, thin kerf blade.

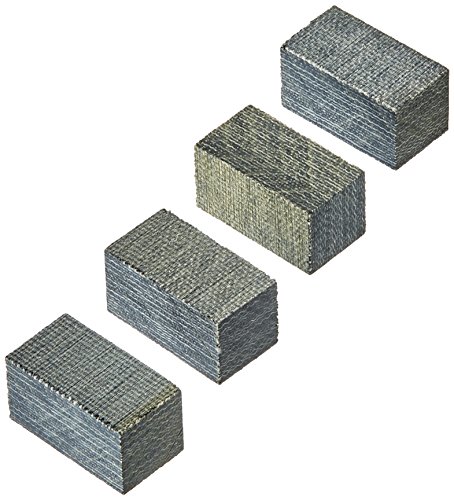

Bandsaw Cool Blocks Blade Guide Cool Blocks blade guides are made of a special, non-metallic material that lubricates your bandsaw blades as they cut, keeping them cool and reducing the chance of premature breakage. Since they won’t damage blade teeth, you can really snug them down for added stability when working with smaller blades. Cool Blocks improve the cutting performance of any blade width, but are required for blades 1/16″ to 1/8″ wide for tight radius work.

Cool Blocks are made to replace the original metal guide blocks which came with many older bandsaws. Cool Blocks are NOT designed to replace roller bearing blade guides. Cool Blocks eliminate friction and heat caused by metal to metal contact so blades run smoother, cooler and far quieter than with metal block guides.

Cool Blocks are designed to replace the metal guides that come installed on your bandsaw. Made of phenolic resin embedded with graphite to reduce friction on the blade, they stay cooler than metal blocks, reducing metal fatigue and extending blade life. Although the blocks are designed to fit specific bandsaws, they may fit other models; check the size of your blade guides.

Shipping & Returns Learn more about policies and international shipping. Learn More Customer Care Talk to a friendly customer care representative to help with your purchase. 1-800-225-1153 Talk to an Expert Get advice on the latest products and help with your projects.

what are bandsaw cool blocks Related Question:

What are bandsaw cool blocks made from?

Cool Blocks are made of a non-metallic composite material– Graphite Impregnated Phenolic Laminate with three synthetic dry lubricants.

What cools the blade on the vertical bandsaw?

These saws are often equipped with a built-in air blower that cools the blade and blows off shavings from the cutting area, ensuring good operator visibility.

What is resawing on bandsaw?

Bandsaw Resawing from the beginning: resawing is cutting a sawn plank of wood into thinner planks on a bandsaw. Thus the cut runs through the plank’s width, which distinguishes bandsaw resawing from ordinary bandsaw rip cuts where the blade runs through the stock’s thickness.

Where are Olson scroll saw blades made?

Olson Saw Company continues to manufacture in Bethel CT, making a wide range of band and scroll saw blades, band saw and power scroll saw accessories, handheld saw frames and other wood working accessories.

Do I need coolant on a bandsaw?

Cutting fluids are important for metalworking bandsaws. They lubricate and cool saw blades and flush heat and swarf in the cutting zone. This extends blade life and increases the band speed the blade can be run at.

What is skip tooth bandsaw blade?

Skip tooth blades have widely spaced teeth at a 0 degree rake angle to prevent clogging when cutting soft wood, non-ferrous metals and plastics. Hook tooth blades have a deeper gullet—that is, larger teeth—and a positive 10 degree rake angle. This helps the blade to feed into the material more aggressively.

What is the best TPI for cutting metal?

Cutting thinner metals, including sheet metal, requires a finer cut. Use 18-24 TPI bi-metal blades. For thicker metals such as steel pipe, angle irons, or tubing, use 14-18 TPI bi-metal blades. For aluminum, an 8-10 TPI blade is best.

Can I put a wider blade on my bandsaw?

An 18-inch diameter wheel can use a 0.032-inch thick blade that is 3/4 inch wide. In general, thicker and wider blades will be the choice when sawing dense wood and woods with hard knots. Such wood needs the extra strength of a thicker, wide blade to avoid breaking. Thicker blades also deflect less when resawing.

Can any bandsaw resaw?

Just about any bandsaw will do acceptable resawing. For example, all the cuts made in this story were done on an inexpensive, 14-in. bandsaw with a 3/4-hp motor. All we did to the saw was add a riser block to increase its capacity.

How many teeth does a bandsaw blade have?

The general rule of thumb is: For wood and soft materials aim for 3 – 6 teeth in the workpiece. For metals and harder materials aim for 6 – 24 teeth in the workpiece.

What is a blade guide?

6Oct by Lori Balkus. Bandsaw blade guides keep the bandsaw blade on track while cutting through materials. Blade guides should be set above and below the saw table to help reduce vibration by holding the bandsaw blade in place while cutting. This assures a precise and quality cut.

Are Olson scroll saw blades good?

Olson Saw Pin End Scroll Saw Blades are an excellent blade collection for any scroll saw user. This collection of a dozen standard in two sizes and six skip tooth blades is both easy to use and versatile, tackling hard and softwood, plastic, and even non-ferrous metal with ease.

What is an Olson saw?

Olson Saw is a brand of Blackstone Industries, LLC. Visit our Company Websites: Blackstone Industries, LLC. Foredom Electric Company. Foredom is the world’s leading manufacturer of flexible shaft power tools and is also known for precision bench-top power tools and a wide selection of quality rotary accessories.