When cutting material up to 1/8-inch thick, use a blade with 10 teeth per inch, such as a 10-inch x 100 tooth or 12-inch x 120 tooth blade. For material up to 1/4-inch thick, use eight teeth per inch. For thicker sheets of aluminum, use a blade with just six teeth per diameter inch.

The task might seem intimidating unless you have the best circular saw blade for cutting aluminum out there as an average one might fail to cut it. Back to menu Best Circular Saw Blades for Cutting Aluminum FAQ. In this section, I answer some of the most popular questions that arise when people go shopping for aluminum-friendly blades to use on their circular saws. Carbide is one of the toughest materials found in circular saw blades and will work perfectly well, provided that the blade’s overall design was made with a view for aluminum cutting.

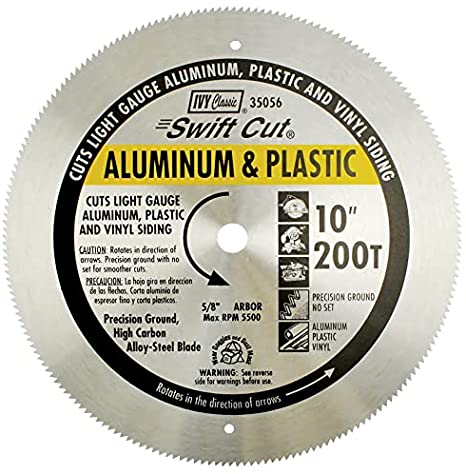

It is why many hesitate at using a wood blade to cut aluminum which is a strong metal compared to wood. You can cut aluminum on a chop saw with a non-ferrous metal cutting blade. You can use a circular saw to cut aluminum with a non-ferrous circular saw blade or a fine carbide-tipped wood blade.

For cutting aluminum, your best bet would be for a blade suited for non-ferrous materials. This blade is designed for cutting non-ferrous tubing, plates, and profiles with 1/4″ maximum wall thicknesses, and there are other blades designed for cutting thicker and thinner aluminum materials. Freud and Diablo are my preferred miter saw blade brands, but I would trust Oshlun too as a 3rd brand choice.

what circular saw blade to cut aluminum Related Question:

What is the best blade for cutting Aluminium?

For cutting aluminum, your best bet would be for a blade suited for non-ferrous materials. These blades typically have “TCG” triple chip grind tooth profiles, which work best on aluminum and plastic materials. Something like the Freud LU77M010 (more info, $62 via Amazon) is what I’d pick.

What is the best TPI for cutting aluminum?

For aluminum, an 8-10 TPI blade is best. As far as the best brand of metal cutting blade, we like MK Morse. If you are cutting cast iron, stainless steel, and high-strength alloys, or for jobs like auto dismantling and fire & rescue, look for a carbide-tipped blade that is at least 8 TPI.

Can I use a steel cutting blade on aluminum?

Ferrous metal blades can be used for cutting all types of metal construction products including steel siding, roofing, steel studs, and other construction steel. Non-ferrous metal blades are designed for cutting products such as aluminum, aluminum trims, copper and brass.

Can a carbide blade cut aluminum?

You should be able to use a carbide-tipped abrasive cutoff wheel for non-ferrous metals like brass, aluminum, copper or lead. Carbide-tipped blades last up to 10 times longer than regular steel ones.

Can Diablo blade cut aluminum?

Diablo’s Aluminum saw blade series is ideal for corded and cordless saws when on-the-job cutting non-ferrous metals such as aluminum extrusions, copper pipe, brass plate, etc.

What is the best tool to cut aluminum?

Tin Snips. Like a pair of scissors, tin snips are an inexpensive handheld tool that cuts straight, or if the blade is curved, can cut curves and circles. Tin snips are ideal for cutting soft metals like aluminum and copper, and are especially useful for cutting sheet metal, gutters, metal roofing, and studs.

How do you cut thick aluminum?

Use a wood-cutting saw with carbide-tipped blades to cut most aluminum. Select a fine-toothed blade and don’t cut aluminum with a wall thickness of more than 1⁄4 inch (0.64 cm). If possible, choose a saw blade that creates narrow kerfs (the notch or slot made by the saw).

Can I cut metal with a circular saw?

Cut Metal with Your Circular Saw It may not be an obvious choice, but fitted with the right blade, a circular saw is a great metal-cutting tool. In our test, it cut through rebar like a hot knife through butter. You can cut mild steel up to about 3/8 in. thick using a ferrous-metal-cutting blade.

What is 18 TPI for cutting?

Blades 12-18 TPI are typically used for metal and denser materials as well as finish cuts in wood. The 18-24 TPI range is almost always used for metal cutting. Pro Tip: Always keep 3 teeth in contact with the material being cut.

What blade is best for cutting metal?

Ferrous blades are ideal for cutting metals that contain iron, such as stainless steel or cast iron. Choose a non-ferrous blade when cutting softer metals, like aluminum or copper. For the best results, use a diamond blade that’s rated to cut the type of metal you are working with.

How many teeth does it take to cut aluminum?

When cutting material up to 1/8-inch thick, use a blade with 10 teeth per inch, such as a 10-inch x 100 tooth or 12-inch x 120 tooth blade. For material up to 1/4-inch thick, use eight teeth per inch. For thicker sheets of aluminum, use a blade with just six teeth per diameter inch.

Can I cut Aluminium with an angle grinder?

An angle grinder is a power tool that can be used for different projects. You can cut metal, aluminium, concrete, bricks, pavers, wood, and other dense materials; you can sand and polish different surfaces to sharpen tools and grind materials. Angle grinders can be used with different types of discs for different jobs.

How do you cut aluminum sheets cleanly?

Bench-mounted tools, such as shears or band saws, cut aluminum sheet relatively slowly and with varying amounts of accuracy. An air-powered sheet metal nibbler or a nibbler head attached to a power drill can cut through galvanized, corrugated aluminum sheet, as well as flat sheet up to 16 gauge.

Does tungsten carbide cut aluminum?

Applications: These tungsten carbide tipped blades are designed to cut aluminium, including bar, die-castings, extrusion and sheet. They are thus ideal for the manufacture of aluminium window frames and many other manufacturing and fabrication tasks. They will also cut wood and plastics.

Can hand saw cut aluminum?

A thin, slightly flexible blade runs across the open portion of the hack saw’s frame. The blade’s teeth vary in size and spacing according to application. Small, closely spaced teeth create fine cuts, usually through soft or thin metal materials, such as copper or aluminum.