Get the most out of your angle grinder by using different types of angle grinder wheels. The most apparent disc and probably the most popular one among different types of angle grinder discs is the grinding disc. Similar to other angle grinder discs, wire wheels are produced in different shapes and sizes because they are used for different purposes.

The secret to successfully using an angle grinder is choosing the right type of cutting disc. Consider how much wood you want to remove and how fast to define the correct cutting disc for your needs. The angle grinder size is determined by the size of the disc, not the length of the tool itself.

This guide to cutting wheels covers the differences between various types of cutting wheels and explains how to choose the right wheel for a given application. CUTTING WHEEL MATERIALS. Cutting wheels typically contain a few different materials – primarily the grains that do the cutting, the bonds that hold the grains in place, and the fiberglass that reinforces the wheels. These cutting wheels are ideal for cutting applications in the metal fabrication, construction, and rail industries, and some of the specialized models can provide precise rail cutting, burr-free cutting, and stud cutting for heavy-duty applications.

Here are seven types of angle grinder discs and their different uses. “In this guide, you’ll learn about seven of the most popular angle grinder discs and their primary uses. This guide will also highlight what many of these discs are made from, which in turn will help you evaluate whether that type can be safely used on your targeted material.” “Diamond discs come in several forms. However, most diamond discs on the market today are cutting discs by nature. Not only that, but diamond discs provide top-tier cutting capacity for jobs that involve extra-dense metal stock.”

An angle grinder is a handheld power tool that can be used for a variety of metal fabrication jobs that include cutting, grinding, deburring, finishing and polishing. An angle grinder tool with the right disc can replace numerous tools and make the most tedious, labour intensive jobs quicker and easier. Whether you are preparing carbon steel for painting or finishing a weld seam , grinding wheels and flap discs are essential accessories for the angle grinder.

what is a angle grinder cutting wheel Related Question:

What is the difference between a grinding wheel and a cutting wheel?

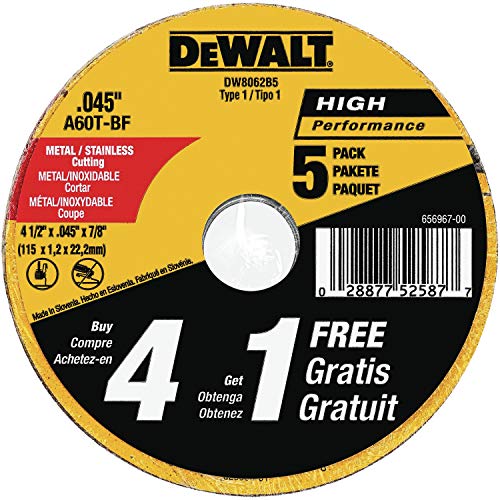

The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. . 045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “Kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”).

What are cutting wheels?

Cutting wheels, or cut-off wheels, differ from grinding wheels in their function and structure. Where grinding wheels use an abrasive to grind large pieces of material off a workpiece from a shallow angle, cutting wheels typically make narrow, precise cuts at 90-degree angles.

Is it safe to use a cut off wheel on an angle grinder?

NEVER attach a Type 1 straight or cut-off wheel to this angle grinder. Use for any other purpose is not recommended and creates a hazard, which will result in serious injury.

Why I shouldn’t use a cutting wheel to grind with?

Cutting-off wheels are thin by design and do not have adequate lateral strength for side grinding. The fiberglass reinforcement is in the wheel to add strength. Using the side of the wheel can damage the fiberglass. This reduces the strength of the wheel and can lead to breakage.

Whats the difference between a cutting disc and a grinding disc?

Clue is in the title, a cutting disc is thin and used for cutting and a grinding disc is much thicker and used for grinding not cutting.

Do cut off wheels expire?

Cut-off wheels and grinding wheels should not be used past their expiration dates, and that’s if they’ve been properly stored and handled. Mishandling or storing discs in certain conditions might lead discs to be discarded earlier.

What part of a cutting wheel should not be used?

Cutting Wheel Safety DON’Ts: Never use a wheel that has been damaged, cracked, or dropped. Don’t use arbor bushings other than those supplied by the wheel manufacturer. Don’t use your wheels to cut any material that they are not specifically designed for. Never use your cut-off wheel to cut wood.

What is the difference between an angle grinder and a cut off tool?

A cut off tool can only be used for cutting, whereas an angle grinder provides you with cutting, shaping, sharpening, grinding, and other functions. A cut off tool can be easily operated with one hand, while the angle grinder requires both hands.

How thick of metal can a cut off wheel cut?

Resinoid-bonded abrasive cutting wheels are available in various sizes and thicknesses. The most popular range is 2 to 16 inches in diameter, and common thicknesses are from 0.045 in. to 1⁄8 in. Thinner wheels remove less material during the cut.

What is Type 27 cut off wheel?

A Type 27 Cut Off Wheel is often referred to as a depressed center wheel. The mounting hardware is in the depressed center, allowing for flush cutting. The Type 27 Cut Off Wheel must be used with an appropriate guard and a depressed center back flange. The center hub protects the user from cutting too deeply.

Whats the difference between grinding and cutting?

Cutting Is a slicing action. Grinding is more of a mashing/grating/pulverising action. You grind food when you chew with your molars. You slice through food using a sharp implement like a knife or scissors.

Can I put a cut off wheel on a drill?

Metal cut-off kits come with some metal cutting discs and a ¼” rounded mandrel that can fit into a pneumatic air die grinder, In a pinch, you can easily fit the mandrel into your drill and use it as a cutter. Cutting discs are extremely versatile. Many backyard mechanics use them to cut off rusted bolts.

What is an angle grinder good for?

An angle grinder is a power tool that can be used for different projects. You can cut metal, aluminium, concrete, bricks, pavers, wood, and other dense materials; you can sand and polish different surfaces to sharpen tools and grind materials. Angle grinders can be used with different types of discs for different jobs.

Can an angle grinder cut steel?

So can an angle grinder cut metal or even dense steel? Yes, it most definitely can. At the end of the day, using an angle grinder to cut metal can be highly effective and extremely safe as long as you have the right equipment and safety tools with you.

Can you use an angle grinder on wood?

Using your angle grinder on wood can be just as, if not more dangerous than metal. Some of the new angle grinder attachments are specifically designed for cutting wood and have many sharpened steel teeth, just like a chainsaw.