Next you need to figure out the width of the blade that will work for the type of cut you plan to make. Once you determine length, width and teeth per inch, you need to figure out what type of tooth configuration is right for the cut type and material you are cutting. There are three main types of bandsaw blade teeth: regular, hook and skip.

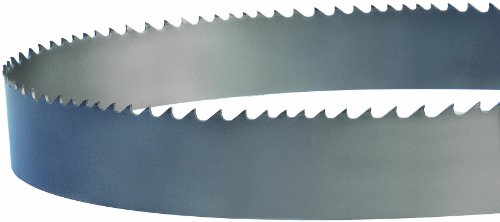

PRODUCT DETAILS. “SuperCut Premium Carbon Tool Steel Blades will cut almost anything that can be filed with a standard hand file, including wood, metals, mild steel, and plastic, provided your blade speed is correct for the material being cut. Made from the toughest alloys, with a high silicon content. They feature precision milled, heat-treated teeth and a flexible back. They are our most versatile blade, suitable for all types of wood, metals, mild steel, and plastics.(Most metal products should be cut with a blade speed of under 200feet per minute.) And of course, they all come with our standard warranty on each weld, even the 1/8” scrolling blade. Plastics are generally cut at slower blade speeds to keep the plastic from melting back together behind the blade as it cuts. Soft metals are cut at speeds of 200 to 1000 fpm, as long as a good release agent is used on the blade to keep the metal from sticking in the blade gullets.

We are going to write this post on the band saw blade types and also their sizes. There are so many blades that are available for the bandsaw. Today we’re focusing some of useful and most used top six bandsaw blades.

SKIP TOOTH. Very similar to the hook tooth but characterized by a straight 90 degree, this tooth has a sharp angle at the junction of the tooth and gullet. Also known as vari-tooth or broach tooth this tooth has varying set angles and gullet depths. RAKER SET. RAKER SET has one tooth set to the right, one tooth set to the left and one tooth is straight.

what is a raker bandsaw blade Related Question:

What is a raker tooth bandsaw blade?

A raker blade has an odd-numbered tooth sequence with a uniform set angle. A basic, three-tooth sequence is left, right, and straight, or unset. The straight tooth is the raker tooth.

What is a raker set blade used for?

RAKER SET. RAKER SET has one tooth set to the right, one tooth set to the left and one tooth is straight. This is used for most production cutting of thick, solid metal sections on horizontal saws.

What’s the difference between bandsaw blades?

Bandsaw blades differ in thickness, width, length, and tooth configuration. Length varies by machine, but the size of your saw’s wheels typically determines thickness and width: Smaller machines (9–12″ wheels) need thinner blades to prevent breaking the welds. They also accept only narrow blades, often 1⁄ 2 ” or less.

What type of bandsaw blade is best for resawing?

Resawing involves making rip cuts in the face of a wide board. So just like you would on the table saw, you’ll want to select a blade with fewer teeth per inch (TPI) than the blades you use for crosscutting or cutting curves. For most 14″ band saws, a 1 ⁄ 2 “-wide blade with 2-3 TPI is a good choice.

What are the three main types of bandsaw blades?

There are three basic tooth styles in bandsaw blades: regular, skip and hook. Regular tooth blades have proportionally spaced teeth and are ideally suited for general-purpose cutting and contour sawing. Regular blades are ideal for cutting thin materials with a fine finish.

How many TPI does a bandsaw blade need?

A coarse tooth blade (2, 3 TPI) should be used for resawing wood and cutting thicker stock up to 8″. A fine toothed blade (18 to 32 TPI) should be used for thinner metals and plastics under 1/4″. For general cutting of 3/4″ wood 4 TPI will provide a fast cut and 14 TPI will cut slow, but leave a smoother finish.

What is a bimetal bandsaw blade?

Bimetal blades are metal cutting blades. They are used on band saws to cut carbon steel, tool steel, structural steel, stainless steel, pipes and tubes, die steel, angles and flat stock, and mixed metal applications.

How do I know what size bandsaw blade I need?

In inches, determine the radius of each wheel, by measuring from the center to the outside of the wheel. Apply the following formula: (R1 x 3.1416) + (R2 x 3.1416) + (2 x C) = Saw blade length. Put a strip of tape on the floor to mark a starting point.

Is a wider bandsaw blade better?

The wider blades are stiffer overall (more metal) and tend to track better on the band wheels than narrow blades. When cutting thicker material, the wider blade has less ability to deviate because the back end, when in the cut, helps steer the front of the blade, especially if the side clearance is not excessive.

How long should a metal bandsaw blade last?

On average your bandsaw blade should last 6 months to as long as a few years depending on what your cutting with it. Make sure to match your blade strength and quality to the project and material your cutting.

What is 14 TPI for cutting?

8-14 TPI blades are capable of cutting wood and the occasional nail. Demo blades fall into this category. 14-24 TPI is the range of metal cutting, PVC cutting and finish cut blades. The blades cut slowly, but leave being a very smooth edge.

How many teeth do you need to resaw a blade?

Typically, a wide 3-tooth-per-inch (tpi) blade provides the perfect blend of aggressive yet smooth cut and sawdust evacuation that resawing requires.

What size bandsaw do I need for resawing?

To get started with resawing, I recommend a band saw of sufficient power and with a large depth of cut. Any motor smaller than 1hp and depth of cut less than 10″ will limit your effectiveness. (Some 14″ band saws have about a 6″ maximum cutso you’d be limited to a 12″ wide book-matched panel or less.)

What steel are bandsaw blades made of?

The three main types of bandsaw blades for cutting metal are carbon steel, high-speed steel, and alloy steel. Carbon steel blades are used for cutting softer metals like aluminum, copper, bronze, brass, and other nonferrous metals.

What type of steel are band saw blades?

The three main choices for blade type in metal cutting applications are carbon steel, bimetal, and, more recently, carbide-tipped.