Angle grinders are one of the most dangerous tools in any workplace and used incorrectly, can and do result in horrific injuries and even death. How to Protect Yourself Both of these risks can be significantly reduced by ensuring guards and handles are properly fitted and used, the correct disc for the job is fitted, and appropriate PPE and suitable clothing is worn at all times when operating grinders. Allow the grinder to run to speed before cutting or grinding.

Because the risk of projectiles can only be minimised and not eliminated, as an angle grinder safety measure to stop injury, you must wear PPE to protect you from the risk of projectiles, especially eye and head protection. You might not be able to stop this, so you should make sure you are in a safe environment to use an angle grinder. In this post, we focused on angle grinder safety issues and different types of angle grinder accidents.

This happens when the angle grinder grabs of jams on the material when cutting, and is more likely to happen if you are using the wrong wheel, or cutting at the wrong speed. Angle grinders are a dangerous tool, and you should wear gloves, eye protection, and hearing protection when you use them. It’s also better to be safe than sorry, so make sure that there isn’t any flammable material near you when using the angle grinder.

Angle grinder accidents are one of the most dangerous hazards for people that use these types of tools. The User should be able to identify them respectively to avoid angle grinder accidents. So that 7″ angle grinder wheel, rated at 7,000 rpm may not be used in a 4.5″ angle grinder which rating is 11,000 rpm.

Mount Prospect, Ill., December 4, 2006 – Two new upgraded small angle grinders from Bosch Power Tools and Accessories – 5-inch 1803EVS and 6-inch 1806E – feature the industry’s first Electronic Kickback Protection technology, which shuts the tool off should the wheel get in a bind situation. Bosch Electronic Kickback Protection provides users with enhanced confidence without sacrificing grinding efficiency and productivity. Restart Protection prevents the startling effects of an unexpected grinder activation, as well as prevents grinders from skating across the floor causing damage to the tool or injury to those nearby.

what is angle grinder kickback Related Question:

How do I stop my angle grinder from Sparkping?

The best way to cut iron or steel without sparks is to use a hacksaw rather than an angle grinder. Attaching a carbide grinding bit to a rotary tool such as a Dremel, for example, limits the amount of sparking and helps remove any small pieces of metal your grinder may miss or cannot reach.

What are most angle grinder injuries from?

In 2008, nearly 25,000 were injured nationwide while using angle grinders (U.S. Consumer Product Safety Commission). The majority of these injuries occur from an abrasive blade shattering, diamond-blade segment loss, or the angle grinder kicking back.

How common are grinder accidents?

‘The Royal Society for the Prevention of Accidents’ Accident Surveillance Systems data ranked angle grinders as the third most dangerous tools, with 5400 injuries recorded annually [2]. The vast majority of these injuries are caused by a shattering of the abrasive wheel [3].

What can you not do with an angle grinder?

Angle Grinder Use Angle grinders generate sparks. When required obtain a hot work permit before use. Keep work area clear of debris and flammable materials. Do NOT use in areas where there is grain dust or other combustible dust accumulation.

What causes grinder kickback?

Kickbacks. Kickback happens when the angle grinder suddenly thrusts back towards the operator as a result of it grabbing or jamming on the materials being worked on. They are common and kick back injuries have included severe cuts and injuries to hands, arms, legs, and the groin region, as well as facial injuries.

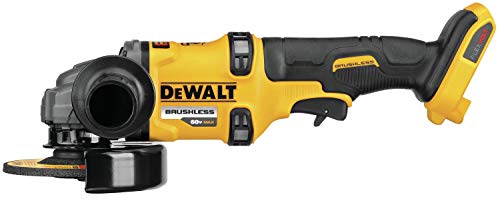

What is an angle grinder good for?

An angle grinder is a power tool that can be used for different projects. You can cut metal, aluminium, concrete, bricks, pavers, wood, and other dense materials; you can sand and polish different surfaces to sharpen tools and grind materials. Angle grinders can be used with different types of discs for different jobs.

Can angle grinders start fires?

Cutting metal with an angle grinder causes a lot of sparks, however, the sparks that result are not that serious of a fire hazard. The reason being that the sparks emitted (generally) do not get hot enough to ignite, therefore, the chances of an accidental fire occurring are quite low.

Can a angle grinder cut wood?

There are several reasons why some users attach a circular saw blade to an angle grinder. The blade of an angle grinder is a grindstone that is used to polish or sharpen metal and stone; it cannot be used for cut- ting wood because it may burn and singe the wood by friction.

Can an angle grinder cut skin?

Angle grinders can cut through stone, concrete, metal and other strong materials, so they have no trouble cutting through human flesh and bones.

Is an angle grinder safe?

They most often spin anywhere from 9000RPM to 11000 RPM, just inches away from your body, face, and hands. So, when you are using an angle grinder wire wheel, grinding disc, or cutting disc, any of them can easily cause severe damage to you or those around you if handled improperly.

What are the potential risks and hazards from using an angle grinder?

Main Hazards The most common causes of injury to operators and nearby workers from angle grinders are lacerations from attachments that break and become projectiles, and lacerations from angle grinder kickbacks.

What PPE is needed for angle grinder?

Wear safety glasses or goggles, or a face shield (with safety glasses or goggles) to protect against flying particles. Gloves, aprons, metatarsal safety boots, hearing protection, and respiratory protection may be required, depending on the work. Ensure the floor around the work area is clean.

Should you use gloves with angle grinder?

“Gloves should be well-fitted and provide good dexterity and the best possible protection against cut or abrasion and heat,” he said, adding that vibration resistant properties are also of benefit, specially on angle grinders that don’t have Milwaukee’s built in anti-vibration features.

How do I clean my angle grinder?

Keep your equipment clean. After each use of the grinder, disconnect power and brush or wipe off dust and sludge (if grinding wet or using a built-in misting system). Tip back the grinder, remove tooling and wipe off the heads. Inspect plates and shroud, make sure screws and bolts are in place and tightened.

How do I choose an angle grinder disc?

depends on the type, shape and thickness of the steel that needs to be cut. For standard everyday jobs on either stainless or mild steel using an angle grinder, choose a 1mm or 1.6mm thickness in your disc. For projects that involve thin metal such as sheet metal, choose a 1.0mm or 0.8mm thinner cutting disc.